Additional information: Dyeing of acrylic, polyester &polyamide

Back to Dyeing of acrylic, polyester & polyamide

DYEING OF SYNTHETIC POLYMER FIBRES

1. DESCRIPTION OF TECHNIQUES, METHODS AND EQUIPMENT

- Polyamide fibres

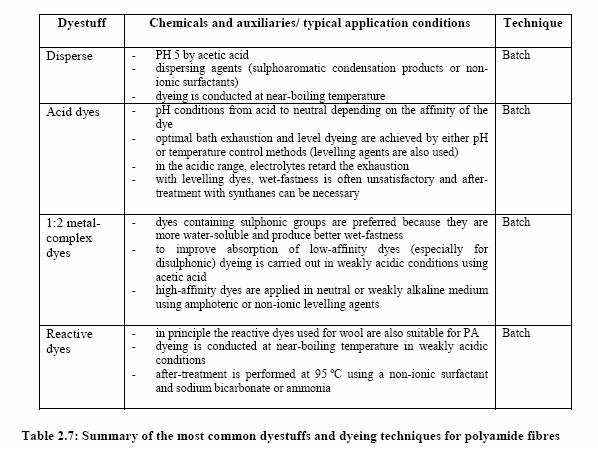

Polyamide fibres (PA 6 and PA 6,6) are easily dyed with various types of dyes. Due to their hydrophobic characteristics, they can be dyed with disperse dyes (non-ionic), whereas thanks to the presence of the groups NH-CO and NH2 – in the polymer chain, acid, basic, reactive and 1:2 metal-complex dyes (ionic) can also be used. However, in practice acid levelling dyes are increasingly used.

Before dyeing, fabrics must generally be pre-fixed to compensate for material-related differences in affinity and to reduce the sensitivity to ceasing during the dyeing process. Pre-fixing can be performed in a stenter frame.

- Disperse dyes

Disperse dyes used for polyamide fibres are mainly azo compounds and anthraquinones. They are applied especially for lighter shades.

The material is dyed in acidic conditions (pH 5) by acetic acid. A dispersing agent is always added to the liquor.

- Acid dyes

As with acid dyeing of wool, with increasing dye affinity, the hydrophobic interaction in the initial phase must be repressed to achieve uniform absorption. This means that for high-affinity dyes the liquor must be sufficiently alkaline at the start and then slowly decreased to optimise exhaustion. The level of acidity of the liquor is regulated either by dosing with acids during dyeing or by adding acid-donors (e.g. ammonium sulphate, sodium pyrophosphate or esters of organic acids) at the start of the process.

Optimal exhaustion and uniform dyeing can also be achieved by controlling the temperature profile.

Auxiliary agents: aionic, cationic, non-ionic surfactants) are normally used to improve the levelling effect.

The wet-fastness of dyeing with acid dyes on polyamide fibres is often unsatisfactory. After- treatment with syntans (synthetic tanning agents) is often necessary. The syntans are added to the exhausted bath or to fresh liquor at pH 4,5 by formic or acetic acid. The material is treated at 70 – 80 °C and is then rinsed.

- Metal-complex dyes

Among 1:2 metal-complex dyes, molecules containing sulphonic groups are the most suitable for polymer fibres.

The absorption of the dye increases with decreasing pH. Dyeing conditions vary from weakly acidic by addition of ammonium sulphate and acetic acid to neutral or moderately alkaline for high-affinity dyes. For high-affinity dyes amphoteric or non-ionic levelling agents are usually added.

- Reactive

In principle, the reactive dyes used for wool are also suitable for polyamides. The dyeing process is carried out in weakly acidic conditions (pH 4,5 -5). The process is started at 20-45°C and then the temperature is increased near to boiling. Non-ionic surfactants and sodium bicarbonate or ammonia are used in the after-treatment step.

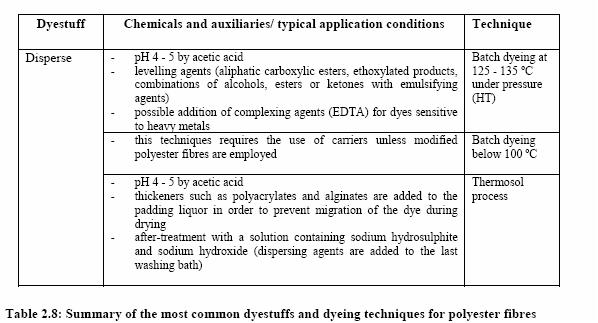

- Polyester fibres

Articles made of pure PES are dyed almost exclusively using batch dyeing techniques and among these, dyeing under high-temperature conditions is the most commonly applied.

Dyeing polyester fibres under atmospheric conditions (below 100°C) was also frequently done in the past with the aid of carriers. Since these substances are ecologically harmful, dyeing below 100°C is no longer in use today for pure PES, unless carrier-free dyeable fibres are employed.

Concerning high-temperature dyeing, the process is usually carried out in acidic conditions (pH 4-5) with addition of acetic acid under pressure at 125-135°C. In these conditions levelling agents are necessary to prevent excessively rapid absorption.

Provided that alkali-stable dyes are used, dyeing in alkaline medium (pH 9-9.5) is also possible. This technique has been developed in order to counteract the migration and deposition of oligomers typical of PES fibres. In fact, olgomeric components (cyclic trimers of ethylene terephthalate are especially harmful) tend to migrate out of the fibre during dyeing, thus forming with the dye agglomerates that can deposit on the textile or on the dyeing equipment. To achieve level effects, ethoxylated products are used as levelling agents.

The termosol process is another applied technique, although it is primarily used for PES/cellulose blends. The dye is padded on the textile together with an anti-migration agent. A drying step at 100-140°C is carried out. Then the dye is fixed (200-225°C for 12-25 seconds).

For light shades, the material needs only to be rinsed or soaped after dyeing. For dark shades, in order to ensure high light fastness, an after-celaning step is normally necessary. This usually consists of an alkaline reductive treatment followed by post-rinsing in weakly acidic conditions.

PES fibres can be dyed with cationic dyestuffs, provided that acidic components (e.g. sulphated aromatic polycarboxylic acid) are used as co-monomers during the manufacturing of the fibre (creation of anionic sites).

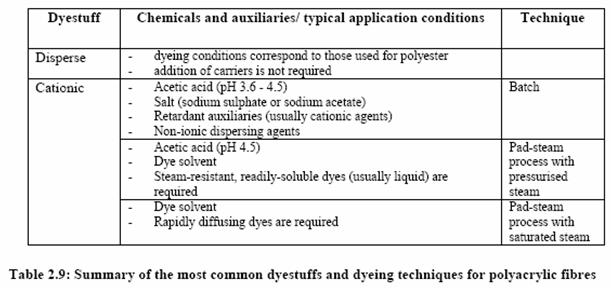

- Acrylic fibres

So called PAC fibres are hydrophobic and contain anionic groups in the molecule. As a result, they can be dyed with disperse and cationic dyes. With the introduction of cationic comonomers in the polymer, the fibre can also be dyed with acid dyes.

Batch dyeing is commonly applied for cable or stock (package dyeing), yarn in hank form or packages and for fabric. Piece dyeing can be performed on beam, overflow, paddle (for knitwear, ready-made bath sets), or drum (socks).

Stock, cable and top can be also dyed on special machine, using the pad-steam process, preferably with pressurised steam to obtain short fixing times. Piece goods, especially upholstery material (velour), are also dyed according to the pad-steam process, but in this case fixing is carried out with saturated steam. This implies longer fixing timers, which means that rapidly diffusing cationic dyes and dye solvents are required.

- Disperse dyes

Disperse dyes are used to produce light to medium-deep shades. The dyeing techniques correspond to those used on polyester fibres. However, dyeing can be performed at temperatures <100°C without carriers. Furthermore, due to the good migration properties of disperse dyes, levelling agents are not required.

- Cationic dyes

Typical recipes used in batch dyeing include an electrolyte (sodium acetate or sodium sulphate), acetic acid, a non-ionic dispersant and a retarding agent. Dyeing is conducted by controlling the temperature in the optimum range for the treated fibre. Finally the bath is cooled down and the material is rinsed and submitted to after-treatment.

Continuous processes commonly applied are:

- pad-steam process (fixation with pressurised steam at more than 100°C) – this process has the advantage of reducing fixing time. Pad liquor typically contains a steam-resistant cationic dye, acetic acid and a dye solvent.

- pad-steam process (fixation with saturated steam at 100-102°C) – this process requires a longer fixing timer. Rapidly diffusing cationic dyes and dye solvents, which exhibit a carrier effect, are required.

When dyeing with basic dyes, special levelling agents (also called retarded agents) are widely used to control the absorption rate of the colourant on the fibre, thus improving level dyeing.

2. NEW TECHNOLOGIES

- a) Changes in the process

1.) Use of non-carrier dyeable PES fibres

The polymer industry has long shown an interest in the entire series of aromatic polyester polymers made from the homologous series of n-methylene glycols. Among these polymers, PET based polyester fibres are the most important ones in the textile industry. They show excellent mechanical properties and resistance to heat, but their high degree of crystallinity makes them non-dyeable below 100°C unless dye carriers are applied.

The environmental concerns raised by the use of these hazardous substances and the proposed techniques to counteract this problem are described in the previous section. An additional option to consider is the use of non-carrier dyeable PES-fibres, such as polytrimethylene terephthalate (PTT) polyester fibres.

Polytrimethylene terephthalate remained an obscure polymer for a long time not because it lacked good physical and chemical properties and potential applications, but because the high cost of synthesis of the starting monomer (1,3-propanediol) has prevented the resulting fibre from being brought to market. PTT polymers are of renewed interest today thanks to Shell’s recent breakthrough in a lower-cost synthesis process.

Fibers made from polytrimethylene terephthalate can be dyed or printed using standard disperse dyestuffs without the need for any special processing steps or carriers to accelerate the dyeing process.

Main achieved environmental benefits

The following environmental benefits are achieved in the dyeing pocess compared to standard polyester fibres (PET type):

- emissions of carriers in the workplace and in the environment are completely avoided

- a lower amount of energy is consumed compared with PET dyed under high-pressure –high-temperature (HT) conditions (PTT is dyed atmospherically at 100°C with excellent dye exhaustion and colourfastness).

Operational data

Disperse dyes are the recommended dye class for PTT, especially for dark shades. Basic dyes may also be used, but only for light shades.

Dyeing equilibrium for a medium shade is obtained in 30 to 60 minutes, depending on the dyes selected. To achieve a good dye utilization without compromising productivity, 30 to 45 minutes holding time at 100°C is recommended.

The recommended dyeing conditions are pH 7 and 100°C (PTT at 100°C was dyed with the same or slightly deeper shade than PET at 130°C).

Source: BAT in textile industry, 2003

2.) Rapid Dyeing

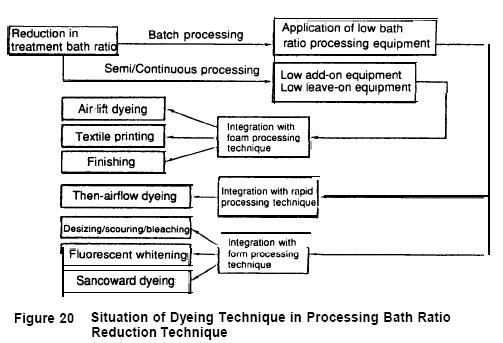

Rapid dyeing which can drastically reduce the dyeing time and achieve remarkable time savings can also achieve great energy conservation effects when applied to polyester. In order to attain these effects, it is necessary to select dyes with assistants and provide appropriate dyeing equipment. Combined with the foam processing technique, the rapid dyeing technique may also have a potential of leading up to the development of new practical dyeing techniques. Figure 20 shows the position of the dyeing technique in the overall processing bath ratio reduction technique.

(Kazuo Shiozawa: Textile Wet Processing Technologies, p.50, Chijin Shokan, 1991)

Source: “Output of a Seminar on Energy Conservation in Textile Industry”, The Energy Conservation Center (ECC), Japan, 1992; Internet: http://www.unido.org/userfiles/PuffK/textile.pdf#search=%22Output%20of%20a%20Seminar%20onEnergy%22

- b) Changes in the heat supply system

No information is available.

- c) Changes in the energy distribution system

No information is available.