Additional information: Dyeing of fibre blends

Back to Dyeing of fibre blends

1. DESCRIPTION OF TECHNIQUES, METHODS AND EQUIPMENT

Natural/synthetic fibre blends are becoming more and more important in the textile industry because this allows combining the favourable technological properties of synthetic fibres with the pleasant feel of natural fibres.

Dyeing of blends fibres is always longer and more difficult as an operation compared to pure fibre dyeing. Despite these disadvantages, dyeing tends to be placed as close as possible towards the end of the finishing process. In fact this enables the dyer to satisfy the requests of the market without the need to store large amounts of material already dyed in flock or yarn form in all available shades.

When dyeing blend fibres, the following methods can be applied:

- the two fibres are dyed in the same tone (“tone on tone”) or in two different shades using the same dyes

- only one fibre is dyed (the colourant is not absorbed by the other ones)

- the different fibres are dyed in different tones

For “tone on tone” dyeing, it is sometimes possible to use the same dye for the different fibres. When dyes of different classes have to be employed, the dyeing process is easier to control when the selected colourants have affinity only for one fibre and not for the other one. In reality, however this situation is exceptional and the dyeing of fibre blends remains a complex operation.

Blend fibres dyeing can be done in batch, semi-continuous and continuous processes. Batch processes include:

- dyeing in one bath and one step (all dyes are added in the same bath in one single step)

- dyeing in one bath and in two steps (dyes are added to the same bath in subsequent steps)

- dyeing in two baths (dyes are applied in two steps in two different baths)

The most common fibre blends will be discussed in the following section.

- Polyester-cellulose blends

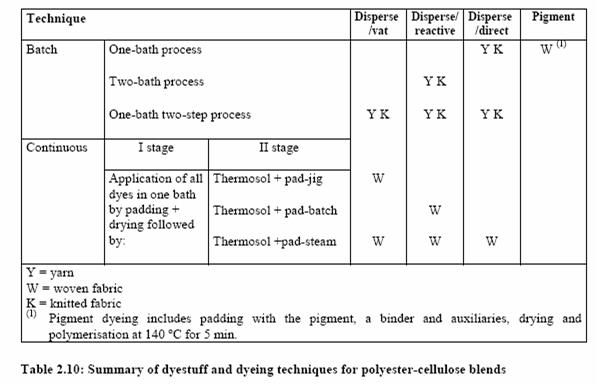

In dyeing PES-cellulose mixtures, disperse dyes are used for the polyester component, while the cellulose portion is usually dyed with reactive, vat and direct dyes. Pigment is also commonly used for light shades.

Disperse dyes stain cellulose fibres only slightly and they can easily be removed by subsequent washing or, if necessary, by reductive after-treatment. Most of the dyes used for cellulose stain PES only slightly or not at all.

PES-cellulose blends are commonly dyed in continuous processes. Nevertheless, for yarn and knitwear, batch dyeing is of major importance.

In batch dyeing, the application of dyes can be done in one or two steps in one bath or in two different baths in subsequent stages. The disperse dye is generally applied at high-temperature (HT) conditions without the use of carriers.

In the one-bath/one-step procedure, special auxiliaries, so-called acid donors, are used, which lower the pH when the temperature is increased. In this way, it is possible to fix the reactive dyes in alkaline conditions and then reach the optimal dyeing conditions (pH 5-6) for disperse dyes by increasing the temperature. Alternatively, it is advantageous to operate at pH 8-10 using alkali-stable disperse dyestuffs, which also avoid oligomer problems.

The one-bath/one-step procedures are preferred, being more economic, but present more difficulties. For example, the presence of salt increases the tendency of disperse dyes to stain the cotton fibre of the blend. Recently developed low-salt reactive dyes are claimed to show good performance and high reproducibility in this application.

In continuous processes the dyes are usually applied in one bath. The fabric is subsequently dried and disperse dye is fixed to the PES component by the thermosol process. Afterwards, the second dye is developed according to the procedure typical of each class, using in general pad-steam, pad-jig or pad-batch processes.

- Polyester-wool blends

Polyester-wool blends are widely used, especially for woven goods and knitwear. The most frequently found ratio is 55:45 PES:wool.

Wool cannot be dyed at the high temperatures typical of the HT dyeing process for PES fibres and PES-cellulose blends. The dyeing time should also be as short as possible as that the wool is not damaged. For large productions it is therefore preferable to dye wool and PES separately in top, blending the two fibres at the yarn manufacturing stage. However quick changes in fashion and short-term planning frequently do not allow separate dyeing.

When dyeing polyester-wool blends, disperse dyes are used for polyester and anionic (acid and metal-complex dyes) for wool.

Only disperse blends are typically dyed according to the following batch processes:

- at boiling temperature with carriers

- at 103-106 °C with little carrier

- at 110-120°C with the addition of formaldehyde as a wool protective agent and with low amounts of carriers or none at all (HT conditions)

Because of the environmental concerns associated with the use of carriers, the first dyeing technique is avoided when possible. In this respect, carrier-free dyeable fibres are also available, which can be dyed at boiling temperature without the use of carriers.

The one-bath process method is preferred in practice; the two-bath process is applied when deep shades and high fastness are required. The material isa first dyed with disperse dyes. A reductive intermediate treatment may be applied before dyeing the wool part. In both dyeing methods, after dyeing, an after-treatment is applied to remove any disperse dye attached to the wool, if the dye used for wool can withstand it. The material is treated with ethoxylated fatty amine in weakly acid liquor at 60°C.

- Polyamide-cellulose blends

Since PA fibres have an affinity for almost all dyes used for cellulose, different possibilities are available for dyeing this blend:

- direct and disperse dyes (pH 8)

- acid or 1:2 metal-complex dyes (pH 5-8)

- vat dyes (exhaust and pad-steam process are used)

- reactive dyes

Application conditions are those typical of each class of dye. They have already been described in the specific sections.

- Polyamide-wool blends

Blends with polyamide/wool ratios varying from 20:80 to 60:40 are used. This blend is particularly important in the carpet sector. More detailed information is therefore reported in the specific section dedicated to this sector.

As general information about the dyeing processes suitable for this type of blend, both fibres have affinity for acid and 1:2 metal-complex dyes. However, since PA is more accessible to the dye than wool, it is dyed more deeply, particularly in the case of light colours. To counteract this effect, special levelling agents (also called PA reserving/blocking agents) are used (mainly aromatic sulphonates). These auxiliaries have a relatively high affinity for the PA fibre and retard the absorption of the colourant on this part of the blend.

Dyeing is performed in the presence of acetic acid and sodium sulphate. Due to limited fastness of acid dyes, 1:2 metal-complex dyes are required for dark shades [186, Ullmann’s, 2000].

- Acrylic-cellulose blends

PAC-cellulose blends are used for household textiles (drapery and table linen) and imitation fur (“peluche”, in which the pile consists of PAC fibres and the back is made of cotton). The percentage of PAC in the mixtures varies between 30 and 80%.

PAC can be dyed with cationic or disperse dyes, while direct, vat or reactive dyes can be used for cellulose component.

The following methods are the most commonly used for dyeing this blend:

- continuous dyeing with cationic and direct dyes according to the pad-steam process (to avoid precipitation of cationic and anionic dyes present in the pad liquor at relatively high concentrations, combination of anionic and non-ionic surfactants are added to the solution)

- batch dyeing (usually according to the one-bath, two-steps method) with cationic and vat dyes or with cationic and reactive dyes

- Acrylic-wool blends

Among synthetic fibres, PAC fibres are the most suitable for obtaining blends with wool that keep a wool-line character. This makes this blend widely used, especially for knitwear and household textiles. The blending ratio of PAC to wool varies from 20:80 to 80:20.

Metal-complex, acid and reactive dyes are the dyestuffs typically used for the wool part, while PAC is dyed with cationic dyes.

Cationic dyes stain the wool fibre. As a matter of fact cationic dyes attach first to wool and then migrate to PAC fibre at higher temperature. Even if well-reserving dyes are selected, dyeing must be conducted for a sufficiently long time (from 60 – 90 minutes) in order to obtain good wool reserve [186, Ullmann’s, 2000].

PAC-wool blends can be dyed using the following exhaustion methods:

- one-bath one-step

- one bath two-step

- two-bath

The first one allows shorter dyeing times and lower consumption of water. However, it is not always applicable because the simultaneous presence in the dye bath of anionic and cationic compounds can produce the precipitation of the formed adducts on the fibre. Precipitation can be prevented using dispersing agents and selecting adequate dyes.

When dyeing with the one-batch, two-step method the use of reserve agents is not necessary. In fact, wool absorbs the cationic dye and slowly releases it, acting as a retarding agent (exerting a retardant effect on PAC).

2. NEW TECHNOLOGIES

- a) Changes in the process

No information is available.

- b) Changes in the heat supply system

No information is available.

- c) Changes in the energy distribution system

No information is available.

Back to Dyeing of fibre blends