Biomass pyrolysis in food production

Back to EFFICIENCY FINDER OF FOOD INDUSTRY

Biomass pyrolysis

The pyrolysis of biomass is a thermal treatment at a temperature of approx. 500°C which results in a production of liquid products that can be used as secondary energy carrier or as chemical products. The main advantage of pyrolysis is the possibility of generation of liquid energy resources that can be used in fuel oil burners and diesel engines. Pyrolysis of biomass can be defined as a process by which the biomass is converted into liquid fuels, pyrolysis-gas and biochar in the absence of oxygen. In contrast to the gasification where syngas and ash are the main products, the technology of biomass pyrolysis is used for the production of liquid and solid energy carriers.

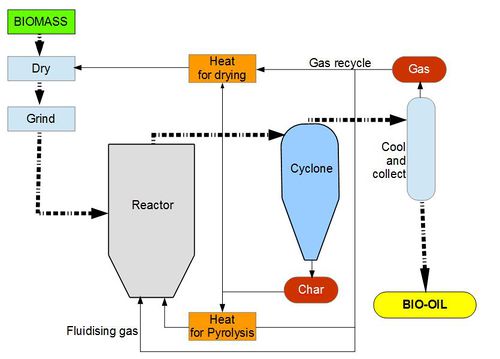

Figure 10: Pyrolysis process of biomass.

The investment cost of a pyrolysis plant are relatively high for small units and decrease significantly for larger ones. This is a result of a great economy of scale effect related to the pyrolysis and biomass pretreatment parts of the electricity generation system. The influence of the plant size on the investment cost is substantial for plants of up to 5000 kW electrical output and continues to decrease with increasing plant output performance.

Although biomass pyrolysis in an attractive option for the conversion of biomass and wastes into clean energy, the technology has not been brought to market maturity.

Table 8: Technical specifications of biomass pyrolysis plants

| Biomass pyrolysis plant parameters | |||||

|---|---|---|---|---|---|

| Typical performance range | Up to 20 MW | ||||

| Energy output | Bio-oil (liquid fuel which can be used as substitute of fuel oil and diesel) | ||||

| Fuel | Solid biomass, waste | ||||