Canned fruit

Back to Information about fruits & vegetables

I. GENERAL DESCRIPTION:

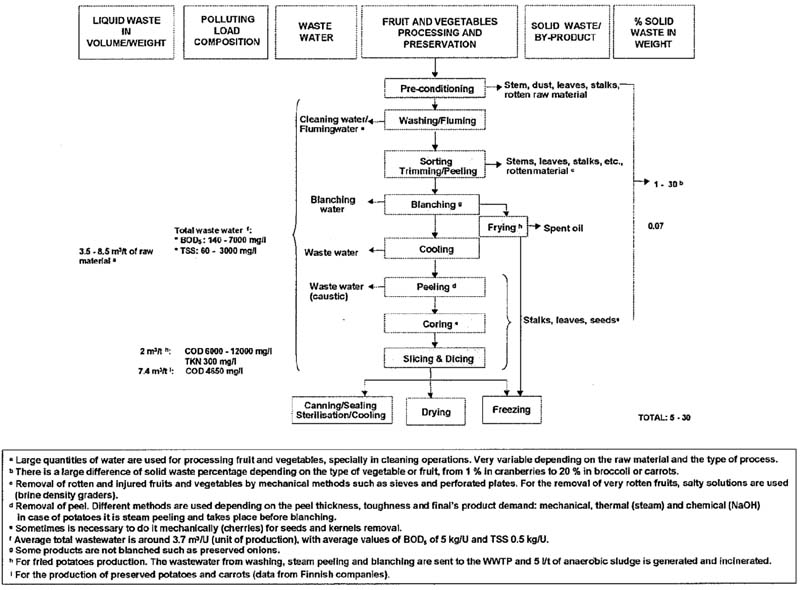

- 1. General Flowsheet of canned fruit production

Figure 1: Fruit and vegetable processing and preservation LITERATURE: BAT for Food, Drink and Milk Industries, June 2005

- 2. Description of techniques, methods and equipment

- (BAT for Food, Drink and Milk Industries, June 2005)

In typical canned fruit processes, the fruit is ideally used as soon as possible after delivery, although it often has to be stored for a time under chilled conditions, e.g. apple. The fruit is first washed, then sorted and possibly trimmed, then graded or cored before peeling. A variety of methods are used for peeling, including abrasive, caustic, steam or mechanical peeling. Peeled fruit may be blanched or transferred to tanks containing materials such as brine or ascorbic acid solutions to prevent browning. If necessary, the fruit may be sliced. Products such as orange segments are subjected to acid and caustic soaks to remove entrained gases, a process known as exhausting. Filling under vacuum conditions avoids the need for exhausting. The container is then sealed, heat processed and cooled. For fruit, a pasteurizing treatment with a temperature under 100°C is sufficient.

- 3. Temperature ranges and other parameters (table)

- (BAT for Food, Drink and Milk Industries, June 2005)

- 4. Benchmark data

No information is available.

- 2. NEW TECHNOLOGIES

No information is available.