Chocolate

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about chocolate, cacao & coffee production

1. GENERAL DESCRIPTION:

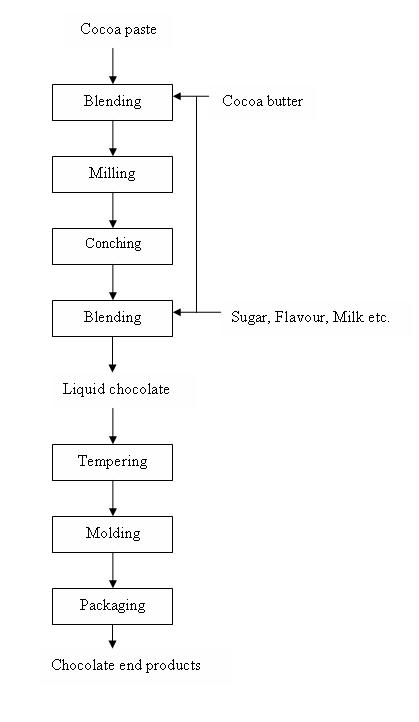

- 1. General Flowsheet of chocolate production

Figure 1: Flowdiagram for choclate production, Literature: Hirschberg, H.G.: Verfahrenstechnik und Anlagenbau, Chemie, Technik und Wirtschaftlichkeit

- 2. Description of techniques, methods and equipment

For chocolate production cacao paste is blended with additives such as sugar, cocoa butter and milk powder and then grinded in roller mills. In the following process step, which is called conching, the chocolate is kept in a liquid state by frictional heat. Conching produces cocoa and sugar particles smaller than the tongue can detect and the prior uneven and gritty texture of the chocolate becomes more plasticized. During the process the temperature rises slowly which leads to an evaporation of volatile matters. Afterwards the liquid mass is tempered for several hours to get a solid structure. The production process ends with the molding and packaging of chocolate bars and other end products.

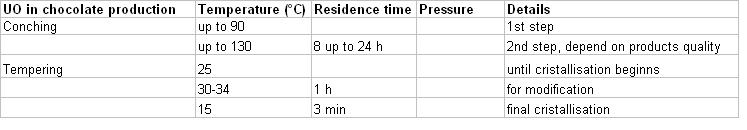

- 3. Temperature ranges and other parameters

Table 1: Parameters of the process steps, Literatur: Schuchmann, H., Schuchmann, H.: Lebensmittelverfahrenstechnik

- 4. Benchmark data

2. NEW TECHNOLOGIES:

- a) Changes in the process

- b) Changes in the energy distribution system

- c) Changes in the heat supply system

Reference: Hirschberg, H.G.: Handbuch Verfahrenstechnik und Anlagenbau, Springer Verlag, Berlin Heidelberg 1999

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about chocolate, cacao & coffee production