Difference between revisions of "Cleaning of bottles and cases in wine & beverages production"

| (3 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | + | Back to [[Subsection DA food|EFFICIENCY FINDER OF FOOD INDUSTRY]] | |

| + | |||

| + | === GENERAL DESCRIPTION === | ||

| + | |||

Water is an essential part of the production of soft drinks and is used at every stage of the life cycle, from irrigating fields in the production of ingredients, to cleaning in the manufacturing stage, as an important ingredient too, and finally it is released as wastewater (BSDA, 2011). Water not in product can account for as much as 70% of overall water use in soft drinks manufacturing (DEFRA, 2013). | Water is an essential part of the production of soft drinks and is used at every stage of the life cycle, from irrigating fields in the production of ingredients, to cleaning in the manufacturing stage, as an important ingredient too, and finally it is released as wastewater (BSDA, 2011). Water not in product can account for as much as 70% of overall water use in soft drinks manufacturing (DEFRA, 2013). | ||

| + | |||

Water use ratio (total water used relative to the volume of soft drink produced) is one of the sector’s main environmental key performance indicators. As an average figure, soft drinks bottling uses a little over 2 litres of water per litre of finished product. The ratio depends on several factors such as the type of products, the type and size of packages, and the efficiency of the production operation. In Europe, this ratio typically ranges from 1.2 to 2.8 litres of water per litre of produced drink. | Water use ratio (total water used relative to the volume of soft drink produced) is one of the sector’s main environmental key performance indicators. As an average figure, soft drinks bottling uses a little over 2 litres of water per litre of finished product. The ratio depends on several factors such as the type of products, the type and size of packages, and the efficiency of the production operation. In Europe, this ratio typically ranges from 1.2 to 2.8 litres of water per litre of produced drink. | ||

| + | |||

According to Beverage Industry Environmental Roundtable this ratio had an average value in 2011 of 2.02 l water/l product, ranging from 1.48 to 3.95 l/l (BIER 2012). There are also some geographical variations, for example the average value for the Spanish sector in 2011 was of 1.80 l water/l product (ANFABRA, 2012). | According to Beverage Industry Environmental Roundtable this ratio had an average value in 2011 of 2.02 l water/l product, ranging from 1.48 to 3.95 l/l (BIER 2012). There are also some geographical variations, for example the average value for the Spanish sector in 2011 was of 1.80 l water/l product (ANFABRA, 2012). | ||

| + | |||

Sorting, inspection and thorough washing and disinfection are necessary in returnable glass bottles with the aim of reducing microbiological contamination of the container and to eliminate any foreign objects and to remove old labels, ink jet coding, etc. | Sorting, inspection and thorough washing and disinfection are necessary in returnable glass bottles with the aim of reducing microbiological contamination of the container and to eliminate any foreign objects and to remove old labels, ink jet coding, etc. | ||

| + | |||

A typical treatment for returned glass bottles includes several steps with increasing and decreasing temperatures along the process. For instance the treatment could be the following: pre-warming of bottles to 30°C with rinsing water, pre-rinsing with warm water at ca. 55°C, immersion of bottles in warm caustic solution (about 1.5% and 60°C) and rinsing with warm water, repeating immersion and rinsing at some 80°C, rinsing at decreasing temperatures (at ca. 80°C, 60°C, 50°C, 30°C) and final rinsing with clean treated water. In non-returnable glass bottles, a rinser replaces the washer (Steen and Ashurst, 2006). | A typical treatment for returned glass bottles includes several steps with increasing and decreasing temperatures along the process. For instance the treatment could be the following: pre-warming of bottles to 30°C with rinsing water, pre-rinsing with warm water at ca. 55°C, immersion of bottles in warm caustic solution (about 1.5% and 60°C) and rinsing with warm water, repeating immersion and rinsing at some 80°C, rinsing at decreasing temperatures (at ca. 80°C, 60°C, 50°C, 30°C) and final rinsing with clean treated water. In non-returnable glass bottles, a rinser replaces the washer (Steen and Ashurst, 2006). | ||

| + | |||

In canning lines cans are usually sprayed with filtered water to remove any possible debris in their internal walls. Cans are emptied by gravity, so usually long production lines are needed in order to ensure all the rinse water drains from the can. Water is usually filtered and recycled within the line. It has to be taken into account that the side walls are prone to denting so special care in can handling is required (Steen and Ashurst, 2006). | In canning lines cans are usually sprayed with filtered water to remove any possible debris in their internal walls. Cans are emptied by gravity, so usually long production lines are needed in order to ensure all the rinse water drains from the can. Water is usually filtered and recycled within the line. It has to be taken into account that the side walls are prone to denting so special care in can handling is required (Steen and Ashurst, 2006). | ||

| + | |||

PET bottles are usually blow moulded directly onto the filling line. Bottles have to be rinsed prior to filling because the risk of bottle contamination within the silo exists, although nowadays many lines tend to remove any silos. The rinsers inject filtered water into the bottles and then rotated into a vertical upturned position to drain water. For some products a cleaning agent and sterile water are also used afterwards (Steen and Ashurst, 2006). | PET bottles are usually blow moulded directly onto the filling line. Bottles have to be rinsed prior to filling because the risk of bottle contamination within the silo exists, although nowadays many lines tend to remove any silos. The rinsers inject filtered water into the bottles and then rotated into a vertical upturned position to drain water. For some products a cleaning agent and sterile water are also used afterwards (Steen and Ashurst, 2006). | ||

| + | |||

According to WRAP´s report on water efficiency for UK Drinks sector (2012) other than water in product, cleaning is usually the largest use of water in a drinks manufacturing plant. The report includes data from studies in the UK which show the specific uses of water in soft drinks manufacturing plants. Rinsing and washing of packages operations sum up to 18% of total water consumption | According to WRAP´s report on water efficiency for UK Drinks sector (2012) other than water in product, cleaning is usually the largest use of water in a drinks manufacturing plant. The report includes data from studies in the UK which show the specific uses of water in soft drinks manufacturing plants. Rinsing and washing of packages operations sum up to 18% of total water consumption | ||

| Line 19: | Line 29: | ||

| − | + | === APPLICATION === | |

Soft drinks | Soft drinks | ||

| Line 27: | Line 37: | ||

| − | + | === TYPICAL PARAMETERS === | |

| − | [[File: | + | [[File:SoftDrinkSector2.jpg]] |

| + | |||

| + | Source: Ganji et al; 2002 | ||

| + | |||

| + | |||

| + | === SOURCES === | ||

| + | |||

| + | * ANFABRA (Asociación Nacional de Fabricantes de Bebidas Refrescantes Analcohólicas), 2012. Memoria 2012. [pdf] ANFABRA. Available from: http://www.refrescantes.es/contents/docs/4000/20121122171310.4178.baja_anfabra_memoria2012_2.pdf. [7 July 2013]. | ||

| + | |||

| + | * BIER (Beverage Industry Environmental Roundtable), 2012. Water use benchmarking in the beverage industry. Trends and observations 2012. BIER. Available from: http://www.bieroundtable.com/files/BIER%20Water%20Use%20Benchmarking%20Report%202012.pdf [7 July 2013]. | ||

| + | * BSDA (British Soft Drinks Association), 2012. The Soft Drinks Industry Sustainability Strategy. Progress Report 2012. London: BSDA. Available from: http://www.britishsoftdrinks.com/PDF/BSDA%20Sustainability%20Progress%20Report%202012.pdf [16 June 2013]. | ||

| + | * DEFRA (Department for Environment Food and Rural Affairs), 2013. Evidence to support the development of a sustainability roadmap for soft drinks: final report.London: DEFRA. Available from: http://randd.defra.gov.uk/Default.aspx?Menu=Menu&Module=More&Location=None&Completed=0&ProjectID=17458 [18 October 2013]. | ||

| − | + | * European Commission, 2006. BREF Reference document on Best Available Techniques in the Food, Drink and Milk industries Steen, D.P. and Ashurst, P.R. eds., 2006. Carbonated Soft Drinks: Formulation and Manufacture. Oxford: Blackwell Publishing Ltd. | |

| − | + | ||

| − | + | * UNESDA, Union of European Beverages Associations, 2009. Environmental Responsibility: Active Innovation. Available from: http://www.unesda.org/sites/default/files/pdf/Environmental_Responsibility.pdf [16 June 2013]. | |

| − | + | * WRAP (Waste & Resources Action Programme), 2012. Water efficiency. Case Study: UK Drinks sector Quantifying water savings opportunities in the UK drinks sector. WRAP. Available from: http://www.wrap.org.uk/sites/files/wrap/Water%20guidance%20FINAL%20010512%20AG.pdf [16 June 2013]. | |

| − | |||

| − | + | ===== Case Studies ===== | |

| − | + | *[[Media: BPE_Hütt_Brewery.pdf |Hütt Brewery]] | |

| − | |||

| − | + | Back to [[Subsection DA food|EFFICIENCY FINDER OF FOOD INDUSTRY]] | |

Latest revision as of 22:49, 3 December 2014

Back to EFFICIENCY FINDER OF FOOD INDUSTRY

GENERAL DESCRIPTION

Water is an essential part of the production of soft drinks and is used at every stage of the life cycle, from irrigating fields in the production of ingredients, to cleaning in the manufacturing stage, as an important ingredient too, and finally it is released as wastewater (BSDA, 2011). Water not in product can account for as much as 70% of overall water use in soft drinks manufacturing (DEFRA, 2013).

Water use ratio (total water used relative to the volume of soft drink produced) is one of the sector’s main environmental key performance indicators. As an average figure, soft drinks bottling uses a little over 2 litres of water per litre of finished product. The ratio depends on several factors such as the type of products, the type and size of packages, and the efficiency of the production operation. In Europe, this ratio typically ranges from 1.2 to 2.8 litres of water per litre of produced drink.

According to Beverage Industry Environmental Roundtable this ratio had an average value in 2011 of 2.02 l water/l product, ranging from 1.48 to 3.95 l/l (BIER 2012). There are also some geographical variations, for example the average value for the Spanish sector in 2011 was of 1.80 l water/l product (ANFABRA, 2012).

Sorting, inspection and thorough washing and disinfection are necessary in returnable glass bottles with the aim of reducing microbiological contamination of the container and to eliminate any foreign objects and to remove old labels, ink jet coding, etc.

A typical treatment for returned glass bottles includes several steps with increasing and decreasing temperatures along the process. For instance the treatment could be the following: pre-warming of bottles to 30°C with rinsing water, pre-rinsing with warm water at ca. 55°C, immersion of bottles in warm caustic solution (about 1.5% and 60°C) and rinsing with warm water, repeating immersion and rinsing at some 80°C, rinsing at decreasing temperatures (at ca. 80°C, 60°C, 50°C, 30°C) and final rinsing with clean treated water. In non-returnable glass bottles, a rinser replaces the washer (Steen and Ashurst, 2006).

In canning lines cans are usually sprayed with filtered water to remove any possible debris in their internal walls. Cans are emptied by gravity, so usually long production lines are needed in order to ensure all the rinse water drains from the can. Water is usually filtered and recycled within the line. It has to be taken into account that the side walls are prone to denting so special care in can handling is required (Steen and Ashurst, 2006).

PET bottles are usually blow moulded directly onto the filling line. Bottles have to be rinsed prior to filling because the risk of bottle contamination within the silo exists, although nowadays many lines tend to remove any silos. The rinsers inject filtered water into the bottles and then rotated into a vertical upturned position to drain water. For some products a cleaning agent and sterile water are also used afterwards (Steen and Ashurst, 2006).

According to WRAP´s report on water efficiency for UK Drinks sector (2012) other than water in product, cleaning is usually the largest use of water in a drinks manufacturing plant. The report includes data from studies in the UK which show the specific uses of water in soft drinks manufacturing plants. Rinsing and washing of packages operations sum up to 18% of total water consumption

APPLICATION

Soft drinks

Wine

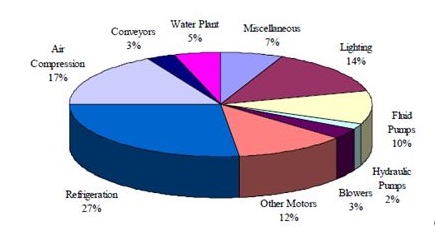

TYPICAL PARAMETERS

Source: Ganji et al; 2002

SOURCES

- ANFABRA (Asociación Nacional de Fabricantes de Bebidas Refrescantes Analcohólicas), 2012. Memoria 2012. [pdf] ANFABRA. Available from: http://www.refrescantes.es/contents/docs/4000/20121122171310.4178.baja_anfabra_memoria2012_2.pdf. [7 July 2013].

- BIER (Beverage Industry Environmental Roundtable), 2012. Water use benchmarking in the beverage industry. Trends and observations 2012. BIER. Available from: http://www.bieroundtable.com/files/BIER%20Water%20Use%20Benchmarking%20Report%202012.pdf [7 July 2013].

- BSDA (British Soft Drinks Association), 2012. The Soft Drinks Industry Sustainability Strategy. Progress Report 2012. London: BSDA. Available from: http://www.britishsoftdrinks.com/PDF/BSDA%20Sustainability%20Progress%20Report%202012.pdf [16 June 2013].

- DEFRA (Department for Environment Food and Rural Affairs), 2013. Evidence to support the development of a sustainability roadmap for soft drinks: final report.London: DEFRA. Available from: http://randd.defra.gov.uk/Default.aspx?Menu=Menu&Module=More&Location=None&Completed=0&ProjectID=17458 [18 October 2013].

- European Commission, 2006. BREF Reference document on Best Available Techniques in the Food, Drink and Milk industries Steen, D.P. and Ashurst, P.R. eds., 2006. Carbonated Soft Drinks: Formulation and Manufacture. Oxford: Blackwell Publishing Ltd.

- UNESDA, Union of European Beverages Associations, 2009. Environmental Responsibility: Active Innovation. Available from: http://www.unesda.org/sites/default/files/pdf/Environmental_Responsibility.pdf [16 June 2013].

- WRAP (Waste & Resources Action Programme), 2012. Water efficiency. Case Study: UK Drinks sector Quantifying water savings opportunities in the UK drinks sector. WRAP. Available from: http://www.wrap.org.uk/sites/files/wrap/Water%20guidance%20FINAL%20010512%20AG.pdf [16 June 2013].