Cocoa

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about chocolate, cacao & coffee production

1. GENERAL DESCRIPTION:

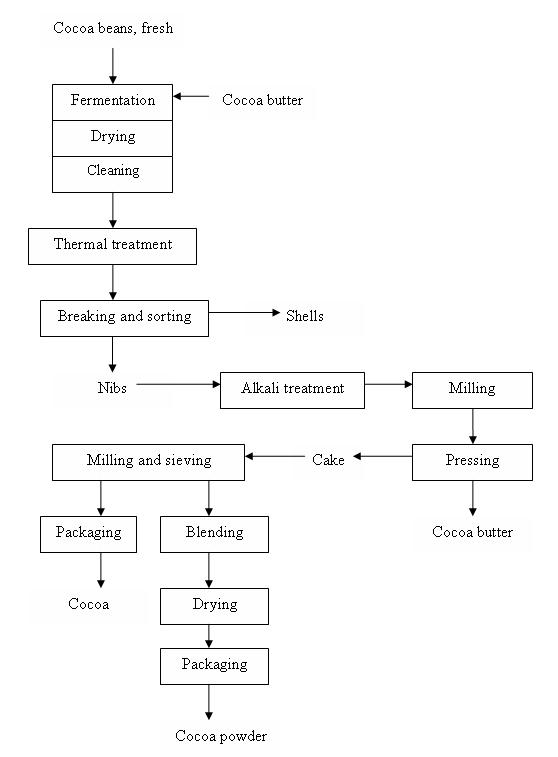

- 1. General Flowsheet of cocoa production

Literature: Hirschberg, H.G.: Handbuch Verfahrenstechnik und Anlagentechnik, 1999

- 2. Description of techniques, methods and equipment

- (Ullmann's Encyclopedia of Industrial Chemistry, Vol.A7, 1994)

Raw beans are received and subjected to a series of washing operations to remove extraneous matter such as fibre, stones, grit, metal, bean clusters and immature beans. The latter two materials may be used for the manufacture of cacao butter. The beans are roasted. Roasting conditions vary depending on the equipment and the desired product, but are typically in the range of 100-140oC for 4-6min. Whole beans or the separated nibs may be roasted. Winnowing is the separation of the outer shell of the bean from the edible nibs and typically consists of cracking the roasted bean between rollers, followed by air classification to remove the shell fragments. The nibs are ground to produce a cocoa liquid whose particle size is further reduced by grinding mills, which are water-cooled. The particle size is important for the manufacture of chocolate drink but less important for chocolate since this requires some further refining. The liquor or nibs from roasted or unroasted beans are likely to be subjected to a process call alkalization, which increases the dispensability of cocoa powder in milk or water when used in drinks. It is also used to modify the colour of the cocoa. Only permitted acids, alkalis and emulsifiers may be used for this process. Cocoa powder is produced by the hydraulic pressing of cocoa liquor to express cocoa butter and to reduce the fat content of the press cake to the desired level. The expressed cocoa butter is used in the manufacture of chocolate. The pressed cake is pulverized to produce a cocoa powder. The final product is then packaged.

- 3. Temperature ranges and other parameters (table)

No information is available.

- 4. Benchmark data (from BAT or from other sources)

No information is available.

2. NEW TECHNOLOGIES:

a) Changes in the process: No information is available.

b) Changes in the energy distribution system: No information is available.

c) Changes in the heat supply system: No information is available.

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about chocolate, cacao & coffee production