Cooling, chilling and cold stabilization in bread , biscuits and cakes

Back to EFFICIENCY FINDER OF FOOD INDUSTRY

Contents

COOLING PROCESSES IN BAKERIES

Description:

Refrigeration systems are a significant consumer of electrical energy in facilities like bakeries which has cold storage. There are four primary components to the typical refrigeration system: 1. the compressor , 2.The condensor, 3. The expansion valve, and 4. The evaporator. In the first stage of the refrigeration cycle, refrigerant enters the compressor as a low pressure gas and is pressurized by the compressor into a hot , high pressure gas. The high pressure gas leaves the compressor and is circulated to the condensor.In the condensor, high pressure gas is cooled via the heat exchanger with cooling medium like ambient air, which causes it to condensate into a hot liquid.

The hot liquid refrigerant then proceeds through an expansion valve , whcih decreases the pressure of the refrigerant, causing it to cool. The cool refrigerant is then circulated to an evaporator. In the evaporator , the refrigerant accepts heat from its surroundings, causing it to vaporize into a low pressure gaseous state. In direct expansion evaporators, the evaporator coils are in direct contact with the object or fluid that is being refrigerated. In indirect expansion evaporators,the evaporator coils are in contact with a carrier medium , such as water , brine or glycol, which is then pumped to the object that is being refrigerated.From the evaporator, teh low pressure gas is fed back to the compressor , completeing the cycle. [Berkley Lab: Energy efficienct Improvement and cost saving opportunities for the baking industry,2012]

Applications:

It is used in all Information about bread, biscuits & cakes production

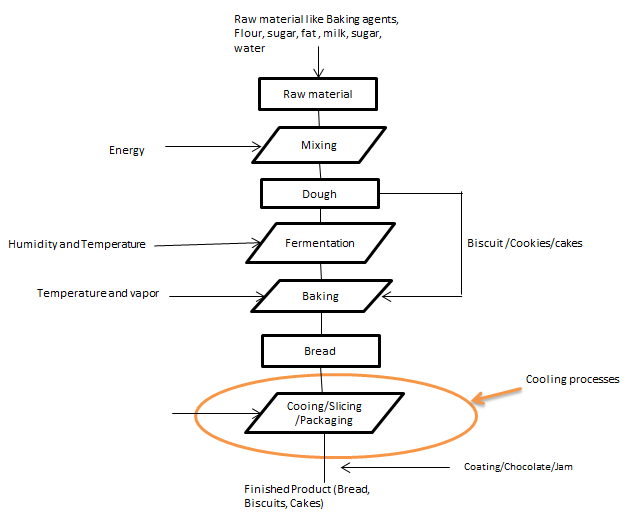

Flowsheet:

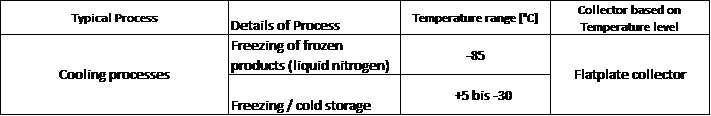

Tzpical Parameters of the Process:

Source:Bayerisches Landesamt für Umweltschutz - Minderung öko- und klimaschädigender Abgase aus industriellen Anlagen durch rationelle Energienutzung - Großbäckerei (2000)