Dried fruit

Back to Information about fruits & vegetables

I. GENERAL DESCRIPTION:

- 1. General Flowsheet of dried fruit production

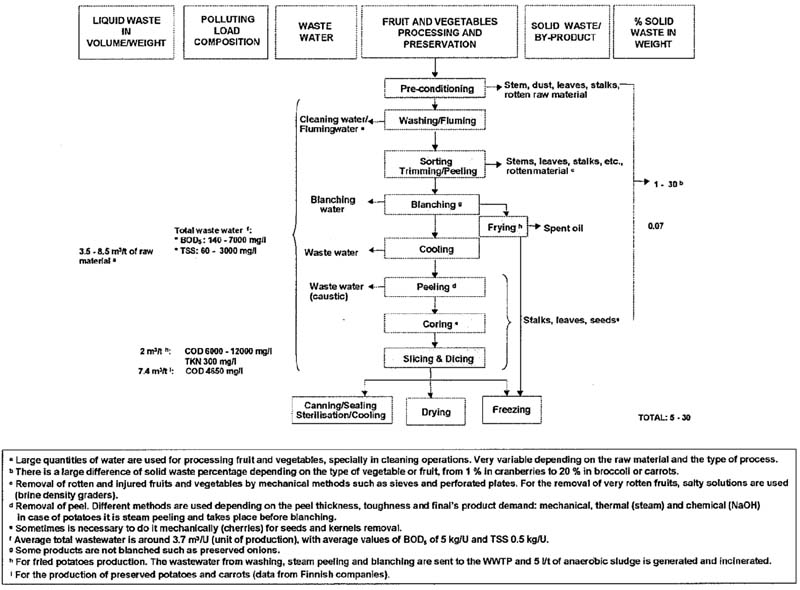

Figure 1: Fruit and vegetable processing and preservation

LITERATURE: BAT for Food, Drink and Milk Industries, June 2005

- 2. Description of techniques, methods and equipment

- (BAT for Food, Drink and Milk Industries, June 2005)

Dried fruit processing uses raw materials such as grapes, apricots, pears, bananas and plums. A basic process consists of sorting, grading, washing, drying and packing. Many fruits are sun-dried at source, although some producers use mechanical methods, typically tunnels through which hot air is passed. Some fruits are sulphited before drying to preserve the fruit and soften the fruit tissue, leading to a faster loss of moisture during drying. In some cases, the fruit is sprayed or dipped after harvesting with a potassium carbonate solution which also contains dipping oil. The composition of the dipping oil varies between producers. For example, some producers use olive oil, others may use mixtures of ethyl esters of fatty acids and free oleic acid.

- 3. Temperature ranges and other parameters (table)

No information is available.

- 4. Benchmark data

No information is available.

II. NEW TECHNOLOGIES:

- a) Changes in the process

No information is available.

- b) Changes in the energy distribution system

No information is available.

- c) Changes in the heat supply system

No information is available.

III. SOLAR SYSTEMS INTEGRATION:

No information is available.