Electrolitically assisted pickling, activation and degraesing in metal industry

From Efficiency Finder

Jump to navigationJump to search

Back to EFFICIENCY FINDER FOR METAL INDUSTRY

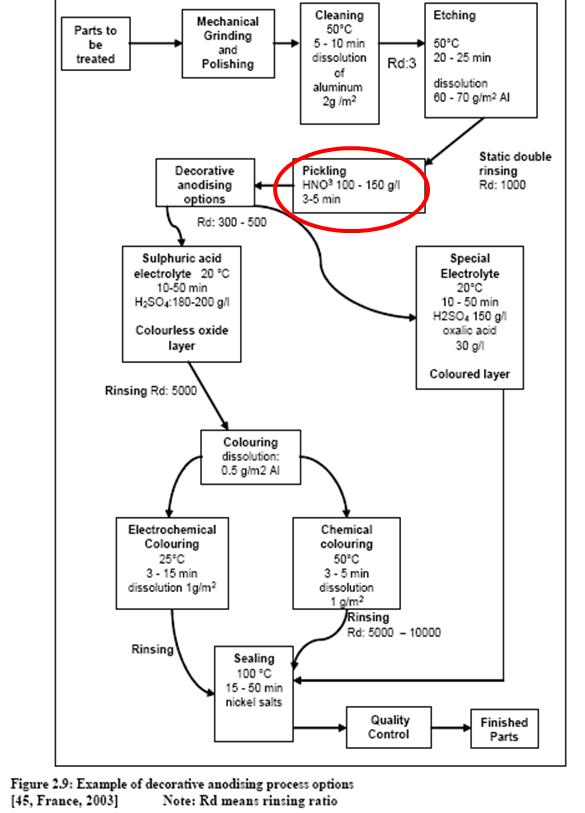

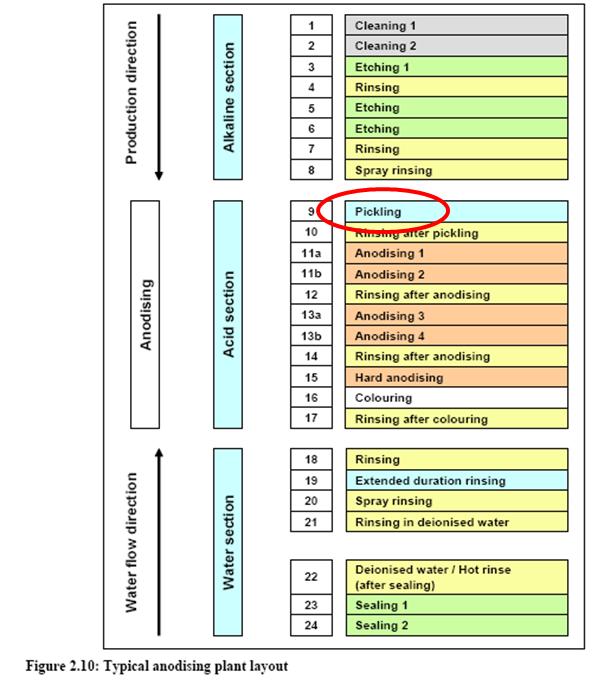

- Electrolytically assisted pickling, activation and degreasing flowsheet

Literature: BAT for Surface Treatment of Metals & Plastics, 2006

- Typical parameters of the process

| Process | Temperature [°C] | Heat transfer medium | Residence time | Chemicals | Concentration | Details | Literature |

| Activation prior to phosphating | <40 | pH: 8-10 | BAT for the surface treatment of metals and plastics, August 2006 |

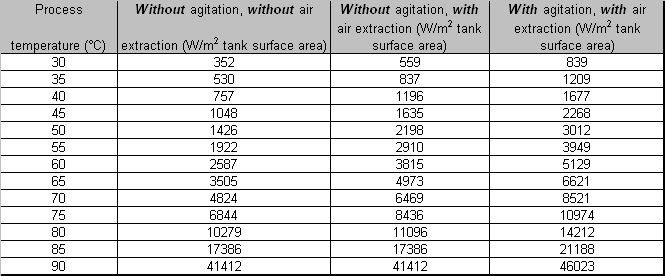

- Energy losses from the surface area of heated process solutions

LITERATURE: BAT for the Surface Treatment of Metals and Plastics, May 2005