FSB Fässer (Austria

Back to EFFICIENCY FINDER FOR METAL INDUSTRY

Back to Information about iron

- 1. Solar integration

Solar thermal plant for fresh water and reflux heating

- 2. Industry Sector

Cask assembly and surface treatment

- 3. Industrial application

Solar thermal plant for fresh water and reflux heating

- 4. Process description

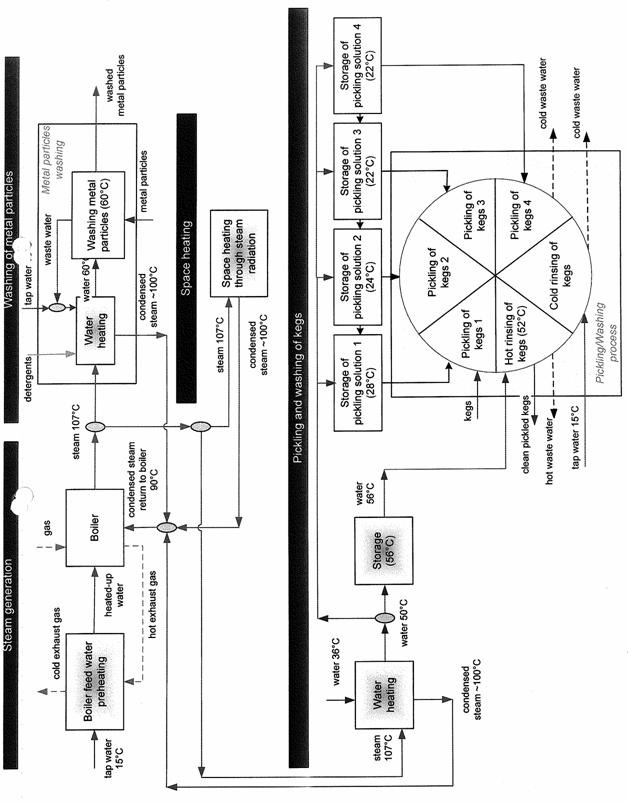

- Process flowsheet:

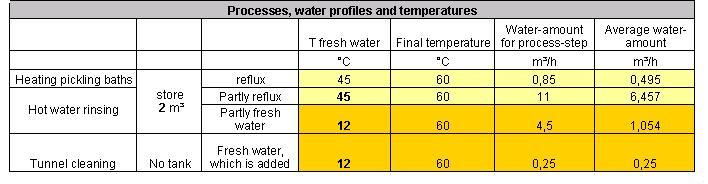

- Processes:

Operation times: 5 day/week, one ship: 5:00 – 13:00

- 5. Energy flows and temperature ranges

- Main heat supply system and fuel:

- Gas and elextricity Steam-boiler: power 1.070 kWh Total energy demand: 2.200.000 kWh, whereof 480.000 kWh electricity and 1.720.000 kWh gas

- Energy balance for the processes: 477.709,03 kWh

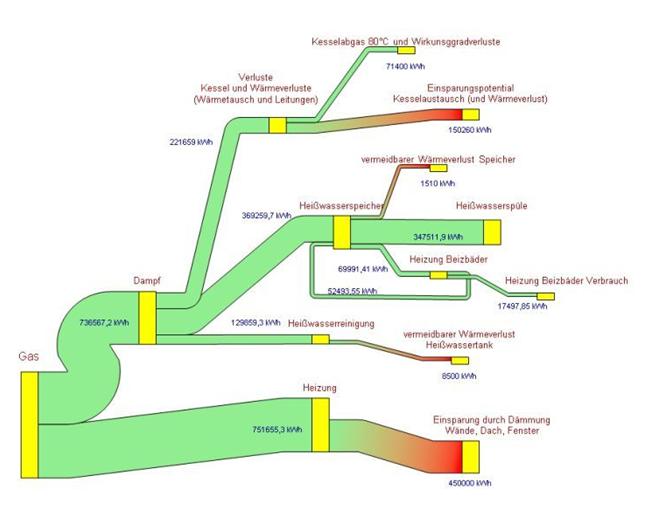

- Energy consumption (Sankey):

Energy-balance of the company FSB, including avoidable energy-losses (process-heat from gas)

- 6. Solar Thermal Plant

- Used scheme and description:

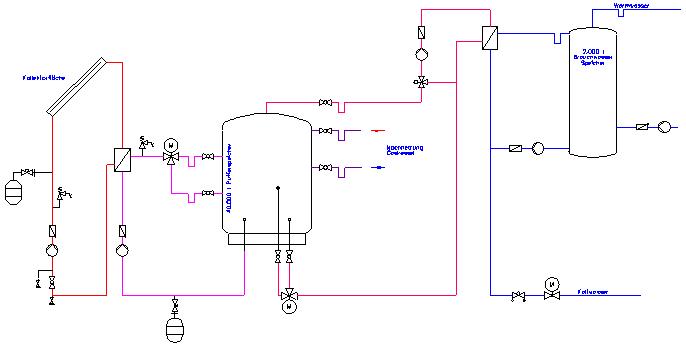

Hydraulic scheme, which is the basis for the simulation:

Description:

The solar thermal plant feeds a puffer-store, which is connected to a process-water store via a heat-exchanger. Fresh water and the warm reflux from the processes are fed into the process-water store. The average mix temperature in the store is 39,8 °C. The water in the process-water store is then heated up to 60°C via the heat-exchanger and the solar thermal plant. Warm water with 60°C can be taken continuously from the store for the processes. If there is not enough solar radiation, the boiler is used for supplying enough heat.

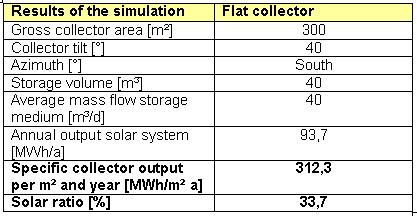

- Performance of the simulated solar plant:

- Pictures of the built solar system:

No information available.

7. Energy savings

- Pinch analysis results:

No information is available.

- Energy savings:

Considering a total efficiency factor of 85 %, 110.200 kWh of gas would have to be provided, to get 93.700 kWh energy. The production of 93.700 kWh solar energy results in a saving of 3.527 €/year of fossil energy, if calculated with the present energy prices.

Energy balance for the processes: 477.709,03 kWh Energy saving potential with solar heat: 93.700 kWh

- 8. Economic evaluation

- Economic parameters of the built solar system:

The economic evaluation was done for a combination of energy saving concepts (heat insulation, bio mass boiler…), not only for the solar integration described.

LITERATURE: AEE INTEC/JOANNEUM RESEARCH (“Styrian Promise”)

Back to EFFICIENCY FINDER FOR METAL INDUSTRY

Back to Information about iron