Forming and draining for hygiene paper

Back to Subsection DC paper

Tissue is usually a product where the single layers produced in the paper machine are combined in a multi-layer product after the paper machine in a separate unit. This is because of its low basis weight sheet (down to 12 g/m2 on the wire). The main product properties are softness and smoothness, cleanliness, high absorption capacity and strength. The conversion into finished products is often integrated with the tissue production, i.e. tissue mills often sell their products to the end-consumer (including packaging).

Tissue is predominantly made of bleached chemical pulps or deinked recovered fibres (see Chapter 6). In the case of using paper for recycling, the fillers and fines (very small fibres unsuitable for tissue manufacturing) have to be removed. Normally, a mixture of different shares of virgin and recovered fibres is used. For the processing of paper for recycling with deinking, the reader is referred to Section 6.1.3.4. If virgin fibres are used, the paper mill can be integrated or non-integrated into pulp-making. For non-integrated tissue-making mills, additional water is required to repulp the virgin fibres.

In tissue-making, different processes are used to manufacture different types of tissue products with different characteristics. The way of drying the tissue determines most of the tissue characteristics. There are three main types of processes:

- conventional tissue-making,

- through-air drying process (TAD),

- hybrid processes.

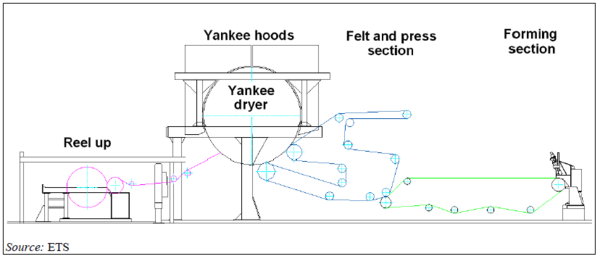

The most common process is the conventional tissue paper machine with a conventional Yankee dryer (see Figure 7.6). The tissue sheet is formed on a moving fabric, where water is removed by drainage. The sheet is then transferred to a felt where more water is removed by pressing and vacuum. Here the tissue sheet is compressed. For full drying, the sheet is transferred to a Yankee cylinder and dried by adding steam to the cylinder and blowing hot air onto the tissue surface. Finally the tissue is removed from the Yankee cylinder by a creping blade and the sheet is reeled up.

Figure 1: CWP tissue process with conventional Yankee dryer

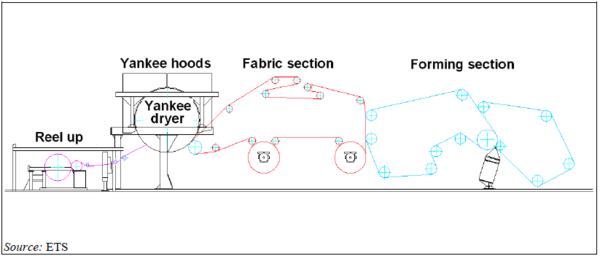

To make bulkier tissue with high absorbance and softness, the TAD process was developed about 20 years ago. In the TAD process, pressing of the tissue web is minimised. The tissue sheet is formed on a moving fabric where water is removed by drainage and vacuum. Because of the high moisture, the sheet is moved to a second fabric using a vacuum. To obtain the bulkier characteristics, the sheet is dried by passing it over one or two TAD dryers where hot air (>350 °C) is blown through the sheet. Finally the sheet may be transferred onto a Yankee cylinder for further drying with steam and hot air. The TAD process (Figure 7.7) is more energy-intensive but it delivers a very soft and bulky sheet that can absorb up to twice as much water as conventional tissue while utilising less fibre. The higher energy needs are linked to the reduced pressing and multistep drying with TAD and Yankee dryers while power use is higher due to the vacuum requirement and large airflows (fans).

Figure 2: TAD tissue process with two TAD drying cylinders and Yankee dryer

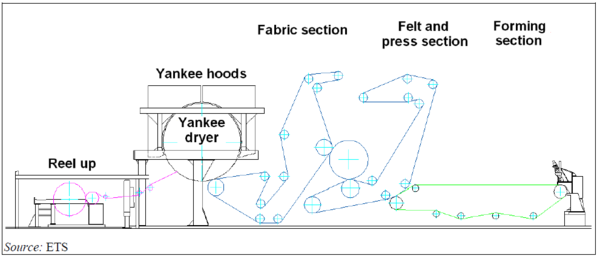

During the last decade, new hybrid technologies have emerged that also enable small machines to produce a higher bulk tissue than conventional machines with a texture or structure similar to that produced in a TAD machine. In terms of energy consumption, these hybrid tissue technologies are somewhere in between conventional and TAD tissue: they have lower energy consumption than TAD tissue, but higher than the conventional tissue machines referred to. Hybrid technology deployment in Europe is still limited but is increasing. Figure 7.8 gives an example of a patented hybrid technology.

Figure 3: A patented hybrid tissue-making process

Each tissue-making process produces a specific kind of tissue suitable for different applications. Kitchen towel requires high strength and good absorption while for facial tissue softness is most important. Premium bathroom tissue requires high softness and strength while low-quality/cost bathroom tissue has less softness and lower strength. The surface structure of the tissue is the basis for these characteristics. Multilayer products are made to further improve the above characteristics.

During the stock preparation process there are only small quantities of losses of fibrous material (1 – 2 %). Air emissions depend mainly on the energy supply and the layout of the drying process. Tissue mills tend to use somewhat higher volumes of fresh water on showers than other paper mills because the cleanliness of wires and felts are crucial for the very light-weight sheet formation. Many tissue machines make frequent changes of grades and/or colours for different products, reducing somewhat the efficiency of the use of raw materials, water and energy. This phenomenon is more pronounced for small mills with only one paper machine. Depending on the product properties, chemical additives are used which may result in waste water contamination. As an example, the use of organic halogenated resins for wet strength improvement leads to higher levels of AOX in waste water.

Source: Best Available Techniques (BAT, Reference Document for the Production of Pulp, Paper and Board, 2015

Back to Subsection DC paper