Fruit juice/pulp

Back to

I. GENERAL DESCRIPTION:

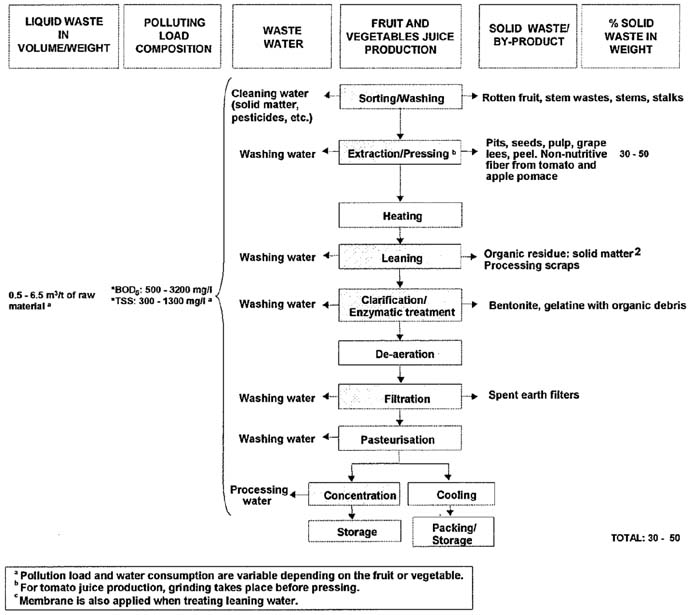

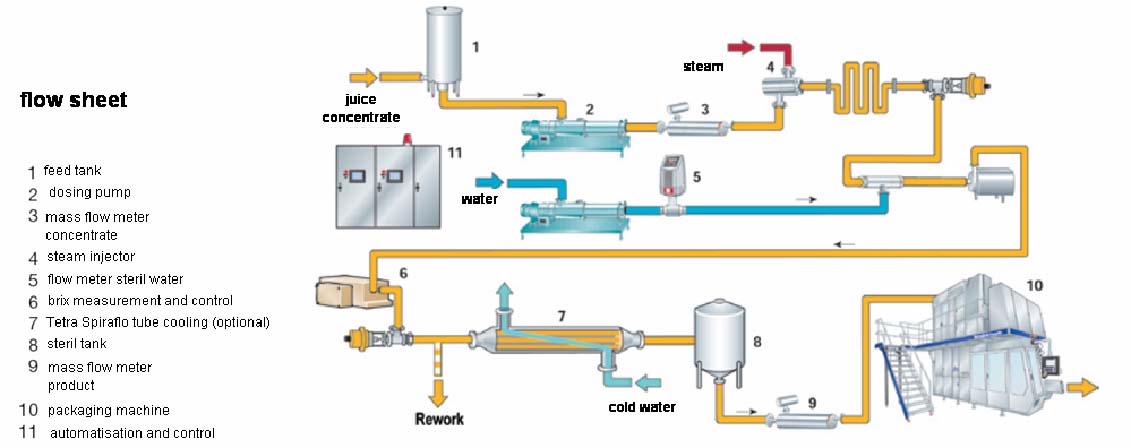

- 1. (a) General Flowsheet of fruit and vegetable juice manufacturing

Figure 1: Fruit and vegetable juice manufacturing LITERATURE: BAT for Food, Drink and Milk Industries, June 2005

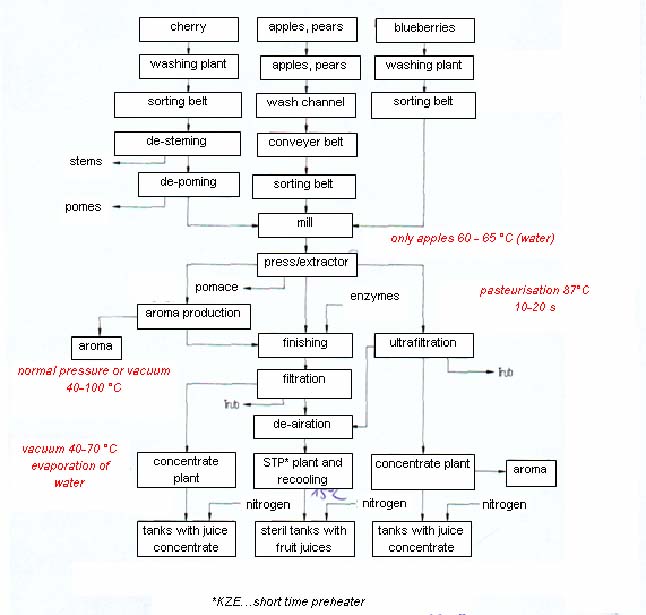

- b) General Flowsheet of fruit juice and concentrated fruit juice production from pome fruits

Figure 2: Production of fruit juice and concentrated fruit juice from pome fruits. Literature: ?, G.Fuchs und W.Knechtel

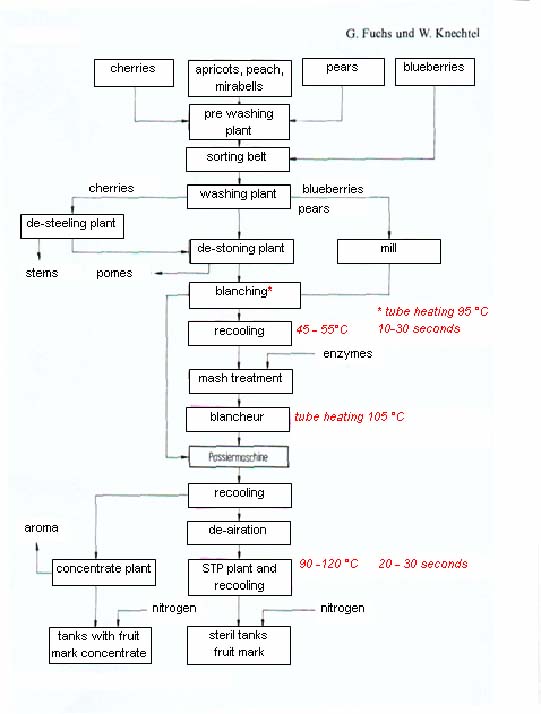

- (c) General Flowsheet of fruit pulp production

Figure 3: Production of fruit pulp. Literature: ?, G.Fuchs und W.Knechtel

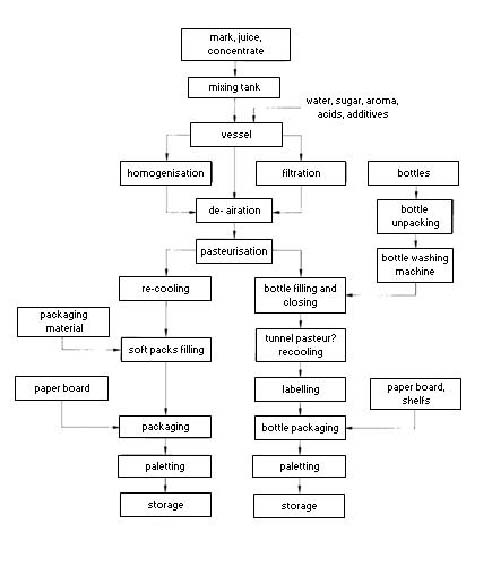

- (d) General Flowsheet of fruit and vegetable juice/pulp production

Figure 4: Production of fruit and vegetable juice/pulp. Literature: “?“, G.Fuchs und W.Knechtel

- (e) General Flowsheet of fruit juice pasteurization

Figure 5: Fruit juice pasteurization

- 2. Description of techniques, methods and equipment

- (BAT for Food, Drink and Milk Industries, June 2005)

The bulk of the world fruit production is from citrus fruits, mostly oranges, pomes; from apple and pear type fruits and from vine fruits. Some stone fruit juices are manufactured but in much smaller quantities. In a typical citrus juice process, the fruit is sorted, graded and washed to remove extraneous matter such as sticks and leaves, adhering dirt and insects. The fruit is then passed through oil extraction equipment where it is subjected to hundreds of small cuts of the skin to rupture the oil sacs and release the citrus oil which is removed by washing. Oil extraction may be carried out after juice extraction. The fruit juice is mechanically extracted and screened to remove excess pulp, pieces of skin and seeds. The screened juice is preserved by a number of methods such as canning, aseptic processing, chemical inhibition, freezing and membrane separation. It may be concentrated before packaging to reduce transport costs. The juice may be clarified before or after preservation. A typical pome juice process includes similar processes but without an oil extraction step. The fresh fruits are delivered to the processing installation and unloaded, washed, sorted and then crashed after eventual coring or pitting, e.g. for peaches and apricots. The white fruits are heated to avoid enzymatic browning. The crashed fruits are then strained and refined to extract the juice. For apple juice, the juice is sometimes clarified with an enzymatic treatment and filtration. Orange, apple and tomato juices are often concentrated, normally by evaporation or in some cases by RO or cryoconcentration. The juice is obtained either from fresh fruits or from reconstituted concentrates from citrus, pineapple and other tropical fruits. It can be packed directly, as it is the case with juices, or mixed with sugar and water, as it is the case with nectars. The juices are then de-aerated and hot filled into bottles or cans. Because of the low pH, filling with a HTST pasteurization treatment is sufficient to stabilize the product when followed by bottle sterilization in a steam tunnel. Aseptic packaging is carried out by pasteurizing, cooling and filling, all in aseptic conditions. The filling is carried out in cardboard bricks or performed bricks.

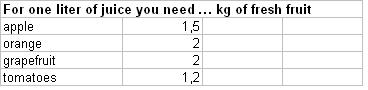

Table 1: Examples for the ratio juice/fresh fruit

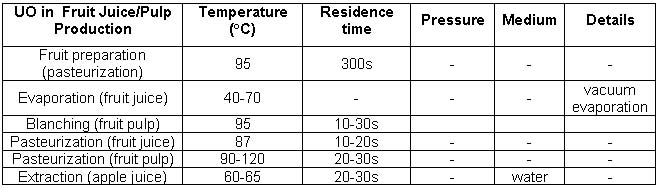

- 3. Temperature ranges and other parameters (table)

- 4. Benchmark data

No information is available.

II. NEW TECHNOLOGIES:

- a) Changes in the process

No information is available.

- b) Changes in the energy distribution system

No information is available.

- c) Changes in the heat supply system

No information is available.

III. SOLAR SYSTEMS INTEGRATION:

No information available.

Back to