Heat treated vegetables

Back to Information about fruits & vegetables

I. GENERAL DESCRIPTION:

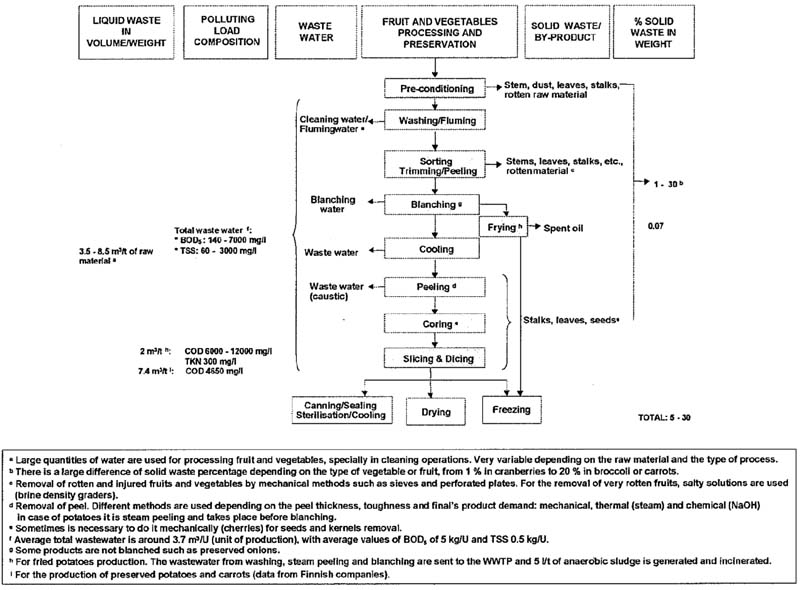

- 1. General Flowsheet of heat treated vegetable production

Figure 1: Fruit and vegetable processing and preservation LITERATURE: BAT for Food, Drink and Milk Industries, June 2005

- 2. Description of techniques, methods and equipment

- (BAT for Food, Drink and Milk Industries, June 2005)

Process conditions vary depending upon the vegetable type, but preliminary operations for both heat treated and frozen vegetables are similar to those described for fruits. They usually involve washing, grading, and screening to remove extraneous matter such as stones and dirt. After washing, the vegetables are peeled and may be trimmed. After peeling the vegetables may be left whole or cut in a number of ways such as sliced or diced. Some vegetables are washed after slicing to remove the surface starch. Most vegetables require blanching. Steam or water blanching are the most common methods. The product is then cooled rapidly. After cooling, the product may be re-inspected and screened before being filled into cans or glass jars, usually with a hot brine, e.g. sugar, salt or acid, and then heat processed. Vegetables generally undergo a full sterilization process as the pH is too high to inhibit microbial action.

- 3. Temperature ranges and other parameters (table)

No information is available.

- 4. Benchmark data

No information is available.

II. NEW TECHNOLOGIES:

No information is available.