Hulls

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Biobased products in fats/oils

Contents

Description

Industrial dehulling before oil extraction is a practice commonly developed in oil mills processing sunflower and rapeseeds at an industrial scale in order to improve the extraction and market of the meal (protein fraction). In addition, the dehulling offers other advantages as higher throughput on crushing equipment (expellers and flakers) and better sunflower crude oil quality since it produces lower wax content.

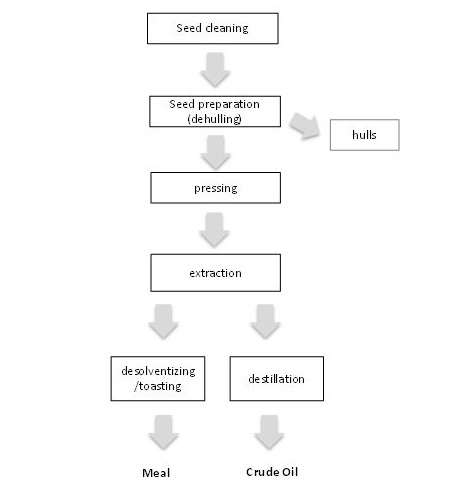

Dehulling step is performed in the oil mills processing sunflower and rapeseeds during seed preparation and generated high amount of hulls.

The percentage of hulls in rapeseed (RSH) is 12-20 %. The percentage of kernels and hulls in sunflower (SSH) are variable according to the cultivar, the size of the seeds and their oil percentage. Most of the values are comprised between 22 to 28 %.

So, a high quantity of hulls are produced in this step that must be valorised in order to prevent waste generation.

Schematic diagram of the crushing process of sunflower and rapeseed

Valorisation techniques

The valorisation of rapeseed and sunflower hulls as biomass for steam production. The sunflower hulls have a calorific value of 16.5 MJ/kg d.m (18.5 MJ/kg d.m. in case of sunflower husk pellet) and contain a moderate level of moisture at 11.4 wt. %, a fairly low ash content of 2.85 wt. % and sulphur content of 0.1%. Sunflower hulls are light in weight and bulky, and are therefore costly and impractical to transport. To compress this material is the indispensable treatment enabling storage and transport on acceptable conditions. The compression of hulls could be done in pelletizing press after a conditioning by steam.

References

Back to Biobased products in fats/oils

Back to EFFICENCY FINDER OF FOOD INDUSTRY