Information about Breakfast cereals

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about bread, biscuits & cakes production

1. GENERAL DESCRIPTION:

- 1.1 General Flowsheet of cereal production

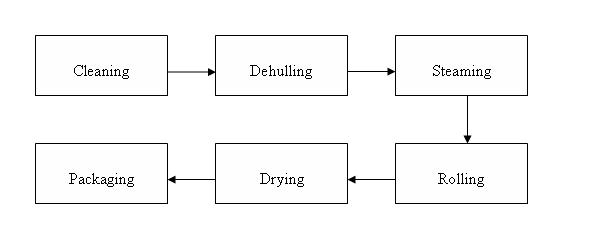

Figure 1: Flow sheet diagram for the production of hot cereals

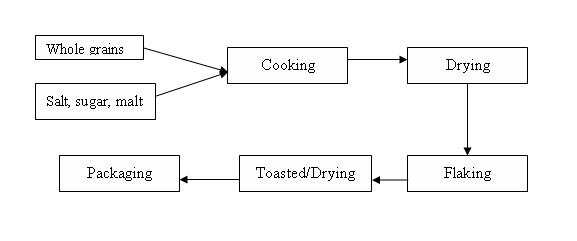

Figure 2: Flow sheet diagram for the production of flaked cereals

- 1.2 Description of techniques, methods and equipment

(BAT for Food, Drink and Milk Industries, June 2005)

Breakfast cereal is a processed food manufactured from grain and intended to be eaten as a main course served with milk during the morning meal. Some breakfast cereals require brief cooking, but these hot cereals are less popular than cold, ready-to-eat cereals. Prehistoric peoples ground whole grains and cooked them with water to form gruels and porridges similar to today's hot cereals. Cold cereals did not develop until the second half of the nineteenth century.

The major grains used in manufacture are corn, rice, wheat, oats and barley. Furthermore BC can be divided into two groups: Ready-to-eat (RTE) and hot cereals (HC) or ready- to-cook. RTE Cereals are frequently made from mixtures of one or several grain components with other ingredients. Extensive processing is required and vitamins and other minerals are added. They packaged in special ways to protect their flavour, texture and nutrition during storage. The group of RTE cereals include products such as flaked cereals, puffed cereals, shredded cereals, granola cereals and extruded expanded cereals. HC are made from a single grain component and only relatively simple processing and packaging technologies are required. Comparing the prices at the consumers’ level reflects a higher prize for a single serving of RTE cereals for the costumers. HC have to be cooked or heated in water before consumption. Important HC are wheat farina, cracked wheat and bulgur and corn grits.

- 8 types of cereal processing

Beyond the basic cereal production process, there are eight distinct cereal processing categories:

- 1.Flaked cereals

A typical formula contains 100 pounds of grain, 6 to 12 pounds of sugar, 2 pounds of malt syrup, 2 pounds of salt, and enough water to achieve 28-32% moisture after cooking. Too much moisture reduces crunchiness. Too little moisture leads to breakage. Cooking time varies depending on the grain. Corn takes about 120 minutes, rice takes 60 minutes, and wheat takes 35 minutes. Example: Corn Flakes.

- 2. Gun-puffed whole grains

Here, the grain must be cooked, followed by a rapid pressure drop in the atmosphere surrounding the grain. This releases steam from the grain as the pressure within the grain tries to equilibrate with the lower pressure surrounding it. Rice and wheat are the only whole grains used for gun-puffing (corn can also undergo this process, but not in whole-grain form). Puffing can be done with single or multiple shot guns. Temperatures vary, staying above 400 degrees F. Puffed cereals rely on a coating (usually sugar) to maintain a crisp texture.

Eg: Golden Crisp/Sugar Crisp

- 3. Extruded gun-puffed cereals

The starting material is flour. Cooking takes place in the extruder, and then dough is formed and cast. Using modified food starch (e.g., like tapioca or potato starch) helps to obtain a high expansion volume and form a film on the cereal while keeping the fat content low. When the dough is cast, the desired shape is created, similar to pasta. Extruded cereals tend to have less browning than other varieties.

Example: Cheerios

- 4. Shredded whole grains

The grain is cooked, cooled, and tempered for up to 24 hours. After this, the wheat is squeezed between one smooth and one grooved roll. A comb runs along the grooved roll to separate the shreds.

Example: Shredded Wheat

- 5. Extruded and other shredded cereals

A blend of the extruded and shredded processes mentioned above.

Example: Life

- 6. Oven-puffed cereals

These cereals are usually rice or corn (or a mixture), and require very high temperatures (550 to 650 degrees F). For more on high cooking temperatures and processed carb foods, see All About Cooking & Carcinogens.

Example: Rice Krispies

- 7. Extruded expanded cereals

Similar to the extrusion process above. Example: Cap’n Crunch

l8. Granola cereals

A mixture of grains, sweeteners, fruits, nuts and other additives baked at 300 to 425 degrees F to achieve a light-brown color and 3% moisture.

Example:granola.

- 1.3 Temperature ranges and other parameters

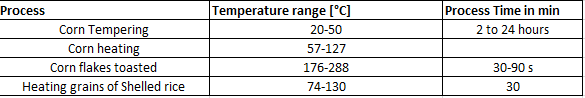

Table 2: Temperature involved in processes, Literature: US 4472449 A:Corn flake process and product,US 2064701 A :Manufacture of rice flakes.

- 1.4 Benchmark data

2. CHANGES IN PROCESSES:

2.1 Fluid Bed Toaster

- 2.1.1Changes in Energy Supply for unique Technology

- 2.1.1.1 Existing Heat/Cool Technology

- 2.1.1.2Changes in Distribution of the Heat/Cool System

- High-velocity air tubes for consistent airflow, ensuring uniform product. During the conveying process, the product is gently agitated with fluidized air. A high rate of thermal transfer results in enhanced product characteristics such as color, texture and size

- 2.1.1.3 Optimisation of the Heat/Cool System

- The fluidization equipment uses high temperature for a broad range of drying, toasting, roasting, puffing and cooling applications. It is employed in RTE (ready to eat) cereal toasting, snack foods, bread crumbs and tobacco.Heat source, recirculation and dust removal configurations are adapted to the customer's operating conditions to assure quicker installation, better plant integration and lower plant operating costs.High-velocity air is distributed across the length and width of the AeroToast processing zones to deliver improved heat transfer, thus lowering operating costs. AeroToast offers customized conveyor bed options to suit the customer's specific product type and handling characteristics for best operational performance.The clean internal design and easy access to the AeroToast helps to minimize cleaning time and maximize operating time. [Source:Buhler Group]

2.2 AeroDry Air Impingement Oven/Dryer

- 2.1.1Changes in Energy Supply for unique Technology

- 2.1.1.1 Existing Heat/Cool Technology

- 2.1.1.2Changes in Distribution of the Heat/Cool System

- Air jets

- 2.1.1.3 Optimisation of the Heat/Cool Systeme. [Source

- Buhler Group]

- It is the optimal solution for rapid and uniform baking, roasting, toasting, cooking, curing, drying and cooling. Impingement processing is ideal for many bakery applications as well as snacks, vegetables, refried beans, tobacco and other industrial products. In the fiber industry, impingement processing offers high drying and finishing efficiency for coated and non-permeable (nanofiber-based) webs. During impingement processing, the boundary layer around the product is broken through high velocity air impinging upon the surface. This process increases the heat and mass transfer rate, and allows efficient removal of moisture, baking, curing, toasting and roasting. AeroDry Impingement Ovens reduce processing time by at least 50% when compared to lower velocity convection or through-air systems.

- Impingement air jets across the entire internal area means that air delivery is consistent for all product on the conveyor bed, eliminating oven "edge effect". Controlled air and temperatures improve operating efficiency while discharging product of consistently high qualit

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about bread, biscuits & cakes production