Information about bread

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about bread, biscuits & cakes production

1. GENERAL DESCRIPTION:

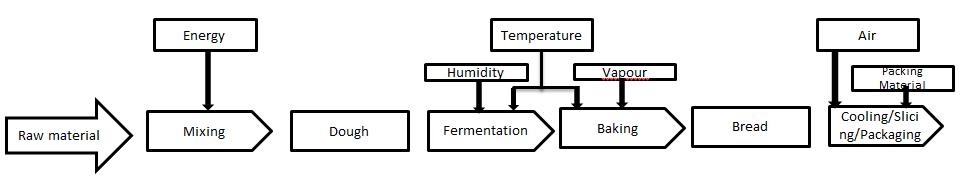

- 1.1 General Flowsheet of bread production

Figure 1: Production of bread.

- 1.2 Description of techniques, methods and equipment

(BAT for Food, Drink and Milk Industries, June 2005)

Bread is the product of baking a mixture of flour, water, salt, yeast and other ingredients. The basic process involves mixing of ingredients until the flour is converted into a stiff paste or dough, followed by baking the dough into a loaf.

;Breadmaking involves the following basic steps:

- Mixing

1. To evenly distribute the various ingredients. 2. Allow the development of a protein (gluten) network to give the best bread possible. Each dough has an optimum mixing time, depending on the flour and mixing method used. Too much mixing produces a dough that is very extensible with reduced elastic properties. Undermixing may cause small unmixed patches which will remain unrisen in the bread. This will give a final loaf with a poor appearance inside.

- Rising (fermentation)

Once the bread is mixed it is then left to rise (ferment).As fermentation takes place the dough slowly changes from a rough dense mass lacking extensibility and with poor gas holding properties, into a smooth, extensible dough with good gas holding properties.

The yeast cells grow, the gluten protein pieces stick together to form networks, and alcohol and carbon dioxide are formed from the breakdown of carbohydrates (starch, sugars) that are found naturally in the flour.

- Kneading/moulding into loaf shapes

Any large gas holes that may have formed during rising are released by kneading. A more even distribution of both gas bubbles and temperature also results.The dough is then allowed to rise again and is kneaded if required by the particular production process being used.uring the final rising (proving) the dough again fills with more bubbles of gas, and once this has proceeded far enough the doughs are transferred to the oven for baking.

- Baking

The baking process transforms an unpalatable dough into a light, readily digestible, porous flavourful product. The physical activities involved in this conversion are complex but the fundamentals of these are explained.

1. As the intense oven heat penetrates the dough the gases inside the dough expand, rapidly increasing the size of the dough. This is called "ovenspring" and is caused by a series of reactions: Gas + heat = increased volume or increased pressure. Gas pressure inside the thousands of tiny gas cells increases with the heat and the cells become bigger.

2. A considerable proportion of the carbon dioxide produced by the yeast is present in solution in the dough. As the dough temperature rises to about 40°C, carbon dioxide held in solution turns into a gas, and moves into existing gas cells. This expands these cells and overall the solubility of the gases is reduced.

3. The oven heat changes liquids into gases by the process of evaporation and thus the alcohol produced evaporates.

4. Heat also has an effect on the rate of yeast activity. As the temperature rises the rate of fermentation increases, and so does the production of gas cells, until the dough reaches the temperature at which yeast dies (approximately 46°C).

From about 60°C onwards stabilisation of the crumb begins. Starch granules swell at about 60°C, and in the presence of water released from the gluten, the outer wall of the starch granule cell bursts and the starch inside forms a thick gel-like paste, that helps form the structure of the dough.

From 74°C upwards the gluten strands surrounding the individual gas cells are transformed into the semi-rigid structure commonly associated with bread crumb strength.

The natural enzymes present in the dough die at different temperatures during baking. One important enzyme, alpha-amylase, the enzyme which breaks starch into sugars, keeps on performing its job until the dough reaches about 75°C.

During baking the yeast dies at 46°C, and so does not use the extra sugars produced between 46-75°C for food. These sugars are then available to sweeten the breadcrumb and produce the attractive brown crust colour.

As baking continues, the internal loaf temperature increases to reach approximately 98°C. The loaf is not completely baked until this internal temperature is reached. Weight is lost by evaporation of moisture and alcohol from the crust and interior of the loaf. Steam is produced because the loaf surface reaches 100°C+. As the moisture is driven off, the crust heats up and eventually reaches the same temperature as the oven.

Sugars and other products, some formed by breakdown of some of the proteins present, blend to form the attractive colour of the crust. These are known as "browning" reactions, and occur at a very fast rate above 160°C. They are the principal causes of the crust colour formation.

- Cooling – slicing and wrapping

In bakeries bread is cooled quickly when it leaves the oven. The crust temperature is over 200°C and the internal temperature of the crumb about 98°C. The loaf is full of saturated steam which also must be given time to evaporate. The whole loaf is cooled to about 35°C before slicing and wrapping can occur without damaging the loaf.A moist substance like bread loses heat through evaporation of water from its surface. The rate of evaporation is affected by air temperature and the movement of cool air around the loaf.In a bakery there are special cooling areas to ensure efficient cooling takes place before the bread is sliced and wrapped.

- Different types exist, depending on the country

;France

80% of the total production is produced is small bakeries. Baguette is the most common eat type of bread.

;Germany

In Germany five principle types of bread are common:

- 1. Wheat bread (at least 90% wheat)

- 2. Mixed wheat-rye breads (min. 50% wheat)

- 3. Mixed wheat-rye breads (min. 50% rye)

- 4. Rye breads (at least 90% rye)

- 5. Bread specialties (by adding non- bread grains such as maize and rice or materials of animal origin such as butter, milk and yoghurt or by using special baking technique)

;United Kingdom

- 1. Sandwich bread

- typical are a high volume soft texture, a fine porous crumb structure and long shelf live properties

- 2. Malt bread

- a kind of sticky, sweet and dark bread

- 3. Rye bread

- commonly a 50:50 mix of wheat flour and rye flour

The production mostly begins with mixing flour, water and other ingredients to form a dough, By incorporation of air good volume, structure and texture is achieved during baking.

Several methods for making bread exist:

- Straight dough process

All ingredients are added together at the start. Then the dough ferments for 2 or 3 hours and afterward it is divided into leaf sized pieces followed by forming them into balls. After a proof time of 10-20 min they are molded and panned.

- Sponge and dough process

The sponge is prepared from part of the flour (ca. 65%), water and yeast. It is just mixed to have an uniform mixture and is then allowed to ferment for 3 or 4 hours. Then the sponge is taken back to the mixer and is mixed with the rest of the ingredients. Then it is given a floor time of 15 min to relax.

- Sour dough

Dough containing a higher proportion of flour or meal requires more acidification. This is generally achieved by sour dough process. Various types of processes were designed to increase the growth of yeast and lactic acid bacteria to give the final dough proper acidity and dough consistency. The proof time for this kind of bread is long (several hours) and for rye bread acidification is required. After the bulk fermentation the dough is divided into loaf sized pieces. Then a floor time is given which allows the dough to relax. The molding process is essentially sheeting followed by curling, rolling and application of pressure. After being molded the dough is panned and is then ready for proofing. During this step the dough increases greatly in volume and can then being baked in the oven.

- Chorleywood process

This kind of process is mostly common in the UK. The mixing and development of dough take place in just one single step in the presence of an oxidising agent. High quality wheat flour is required with a protein content of about 12.5% dry matter together with a high level of starch damage and hence high water absorption. Oxidising improver, fat or emulsifier and extra water and yeast are mixed in at this stage. The whole process lasts between 2 and 5 minutes. All short- time systems require high levels of oxidants. The dough mixing take place with an intensive energy input, then the dough is transferred to a hopper which is sometimes sprayed with oil. It is divided and then allowed to rest followed by final moulding and placing into tins which were sprayed with oil before filling them. Then the dough ferments for a second time and may be cut for baking. Baking times, temperatures and temperature profiles vary largely depending on the type of bread.

The heat is transferred by direct or indirect heat to the loaf. The most common energy sources in baking industry are natural gas and electricity.

After cooling the bread is sliced before wrapping ready for distribution.

- 1.3 Temperature ranges and other parameters

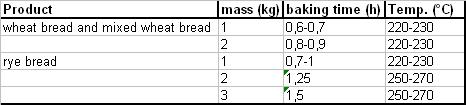

Table 1: Parameters of UO in bread production, Literature: Heiss, R. [Hrsg.]: Lebensmitteltechnologie

The rule of thumb is:

For the production of 1,5 kilo rye bread approximately 1 kilo of wheat, 850 ml of water and 30 gram of salt are required.

The weight percent of wheat in the final product (bread) is about 65%.

Table 2: Baking times and temperatures, Literature: Hirschberg, H.G.: Handbuch Verfahrenstechnik und Anlagenbau, Chemie, Technik, Wirtschaftlichkeit

- 1.4 Benchmark data

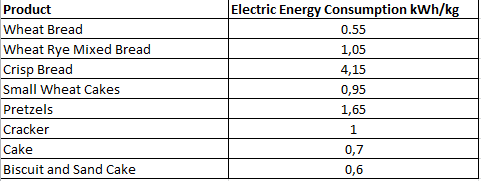

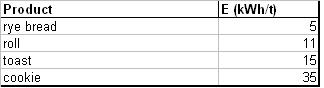

Table 3: Energy consumption of different bakery products, Literature: Heiss, R. [Hrsg.]: Lebensmitteltechnologie

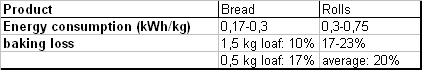

Table 4: Energy Input, Literature: Hirschberg, H.G.: Handbuch Verfahrenstechnik und Anlagenbau, Chemie, Technik, Wirtschaftlichkeit

Table 5: Energy Input during kneading, Literature: Hirschberg, H.G.: Handbuch Verfahrenstechnik und Anlagenbau, Chemie, Technik, Wirtschaftlichkeit

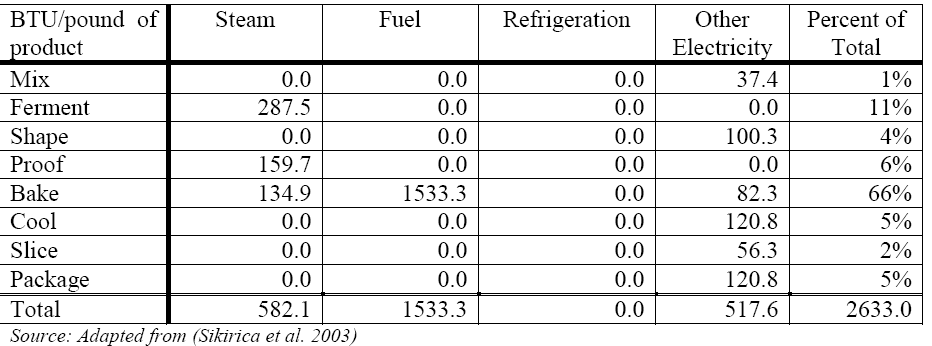

Table 6: Energy Consumption in BTU per pound of product, Literature: Adapted from Sikirica et al, 2003)

2. CHANGES IN PROCESSES:

2.1 Preheating in Baking Oven

- 2.1.1Changes in Energy Supply for unique Technology

- 2.1.1.1 Existing Heat/Cool Technology

- The oven is preheated with hot water

- 2.1.1.2Changes in Distribution of the Heat/Cool System

- Water is replaced by Air

- 2.1.1.3 Optimisation of the Heat/Cool System

- This preheating can be performed by The Air-cooled heat exchanger which is a device for rejecting heat from a fluid or gas directly to ambient air. When cooling both fluids and gases, there are two sources readily available,with a relatively low cost, to transfer heat to air and water.The obvious advantage of an air cooler is that it does not require water, which means that equipment requiring cooling need not be near a supply of cooling water. In addition, the problems associated with treatment and disposal of water have become more costly with government regulations and environmental concerns. The air-cooled heat exchanger provides a means of transferring the heat from the fluid or gas into ambient air, without environmental concerns, or without great ongoing cost. [Source: Basics of Air cooled Heat Exchangers: Amercool Manufacturing Inc.]

2.2 Mist Fermentation

- 2.2.1Changes in Energy Supply for unique Technology

- 2.2.1.1 Existing Heat/Cool Technology

- No use of Ultrasonic smokescreen generator

- 2.2.1.2Changes in Distribution of the Heat/Cool System

- 2.2.1.3 Optimisation of the Heat/Cool System

- Small droplets are created through ultrasound that produces a mist for the fermentation process.This results in improved heat conductivity of the end product without drying out too much.Energy saving during baking (energy saving 17%) Ultrasonic smokescreen generator during fermentation allows a 17% energy saving. Investment costs are between 4000 to 12000 Euros [ Source: Energy-saving mist technology available on industrial scale By Oliver Nieburg]

2.3 Combination of microwaves with halogen lamp heating

- 2.3.1Changes in Energy Supply for unique Technology

- 2.3.1.1 Existing Heat/Cool Technology

- Conventional Baking Oven

- 2.3.1.2Changes in Distribution of the Heat/Cool System

- 2.3.1.3 Optimisation of the Heat/Cool System

- The ‘halogen lamp- microwave combination oven combines the browning and crisping of halogen lamp heating with the time saving advantages of microwave heating. This oven is called as Advantium oven and is produced by GE. Halogen lamp microwave combination baking has been used in bread baking and It has reduced the conventional baking time of breads by about 75 per cent ( Keskin et al., 2004) Specific volume and colour values of bread baked in a halogen lamp microwave combination oven were comparable with that of conventionally baked breads but weight loss and firmness values of those breads were higher as seen in the Table. Breads baked in the microwave oven had the highest specific volume. This can be explained by significant internal pressure which might result in a puffing effect and high volume. The increase in halogen lamp power reduced specific volume and increased weight loss, firmness and colour values of breads in halogen lamp microwave, combination baking. [Source: Emerging Technologies for Food Processing By Da-Wen Sun]

2.4 Proofing in Bakeries

- 2.4.1Changes in Energy Supply for unique Technology

- 2.4.1.1 Existing Heat/Cool Technology

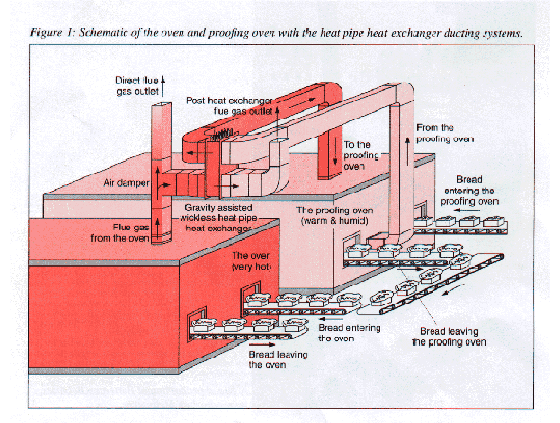

The temperature of the proofer oven is generally about 40 degrees Celsius with a relative humidity of 70-80 percent. Heat required for this part of bread baking is typically produced using steam from gas fired boilers. This is a high energy consuming and expensive way of heating the proofing oven.Loaves of bread are baked in the main oven at temperatures of 300 to 400 degrees Celsius. Excess oven exhaust gases are released into the atmosphere as wasted heat.

- 2.4.1.2Changes in Distribution of the Heat/Cool System

Heat pipes are devices which provide effective heat transfer. They operate by evacuating air and replacing it in part with a fluid such as water. When hot exhaust gases from the baking oven come in contact with the pipe containing the liquid, the liquid first boils and then condenses in cooler parts of the pipe, thereby transferring energy as latent heat. The heat extracted is fed directly into the proofer oven, conserving energy while providing air free of contamination.

- 2.4.1.3 Optimisation of the Heat/Cool System

- The temperature range of the baking oven's flue gas ranges from 300 to 350 degrees Celsius. The waste heat available ranges from 70-80kW and the proofing oven requires energy between 20-45kW. With an air velocity for the system of 1.5 meters per second and an heat exchanger effectiveness of around 65 percent, the waste heat recovery system was able to supply all the heat needed by the proofing oven, thus eliminating the need for any natural gas heating.

- Figure 2: Proofing with Heat Exchanger in Bakeries

- The heat exchanger was manufactured locally from steel pipes charged with distilled water. The RMIT research team supervised the manufacturing process to ensure that the equipment would withstand the high temperature and corrosive environment of the baking oven's exhaust gases.Based on annual saving of 500GJ per year for one shift, cost of natural gas at $4 per GJ, and boiler efficiency of 70 percent, the pay back period is less than 3.5 years. For a three shift operation, the pay back period is reduced to 1.5 years.

2.5 System for building heating and domestic water heating with the Waste heat from flue gas, baking steam and refrigeration system

(With controller, boiler as a heat reserve

- 2.5.1Changes in Energy Supply for unique Technology

- 2.5.1.1 Existing Heat/Cool Technology

- Steam Condensor of the series SK for all oven types with separate steam exhauster.

- 2.5.1.2Changes in Distribution of the Heat/Cool System

- 2.5.1.3 Optimisation of the Heat/Cool System

- NET steam condensers are specially designed for heat recovery from the baking fumes developed. With these devices, the high heat of condensation of Water vapor are recovered in steam condensors.Their performance is higher, the higher the concentration of the water vapor and the lower the temperature of cooling water.However, they are not suitable for flue gas or exhaust air from fume hoods.The heat recovery steam from the baking supplies with NET smoke-condensators generally have a higher heat capacity than the Heat recovery from the exhaust of the oven burner.

- The steam condensator of several juxtaposed ovens, in a common steam condenser is used. This is not only

cost-effective than separate steam condensers for each furnace, but leads also in a more uniform heat output, because in practice, the programs of the individual furnaces are shifted in time.For the connection of several ovens with the steam condensers to become three inputs supplied.Because of their extremely low flow resistance of the vapor can upon the opening the slider on the oven to escape freely. With a suitable selection of the correct type the baking result is not affected.

- The recovered steam from the baking heat can be very good for heating be used by hot water and floor heating. For storage

this heat is a separate buffer memory or the lower portion of Layers of memory required. NET steam condensers are available in different sizes for different large plates supplied. For different installation situations all types supplied in two versions:

- • execution left with inputs on the left side and

- • Execution with right inputs on the right side

- For furnaces with a lower vapor contents, there are special steam condensators. To this end, in individual cases, the time Course of temperature, vapor content and flow are measured. By the laws of nature-related regulation of the heat capacity is overheating NET steam condensators excluded.Removable lid allows for easy and fast cleaning with water. NET steam condensers have no moving parts. They are made of stainless steel with high nickel content (so-called. V4A steel) and have a long service life.

- With this arrangement, the exhaust heat sources, steam and Chiller their temperature level corresponding to different levels of Buffer allocated and thereby optimally utilized.The upper portion of the memory at a higher temperature provides the Building heating system, the entire memory provides the heat for the heating of the Drinking water in a fresh water module. In this way, the heat well used at a lower temperature in the lower region of the memory.For increased demand in heat a boiler to reload the buffer memory is upper area provided.The regulation of the storage charge pump is a good stratification of heat in Storage and saves power for driving the pumps.

- Figure 3: System for building heating and domestic water heating with the Waste heat from flue gas, baking steam and refrigeration system

(With controller, boiler as a heat reserve)

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about bread, biscuits & cakes production