Linear low density polyethylene (LLDPE)

Back to Information about polyolefins

1 General description

This is the youngest of all the PE types. It looks similar to HDPE but has lower crystallinity due to a larger number of short chain branches. Therefore, it also has a lower density (normally lower than 940 kg/m3). However, PE with densities between 930 and 940 kg/m3 is often called MDPE or medium density polyethylene. LLDPE is used to make flexible as well as rigid products. LLDPE is often used in mixtures with one of the materials mentioned previously in order to make thinner films. It is also used in packaging made up of multilayer films. LLDPE is very tough and keeps its shape. These properties are useful for the manufacture of larger objects like lids.

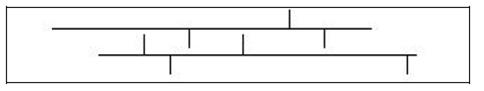

The Figure below shows the molecular structure of LLDPE with the typical short chain branches caused by specific comonomers.

Figure 1: Molecular structure of LLDPE

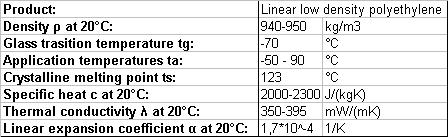

Table 1: Properties of LLDPE, Literature: Hirschberg, H. G.: Handbuch Verfahrenstechnik und Anlagenbau

2 Flow diagram of HDPE production

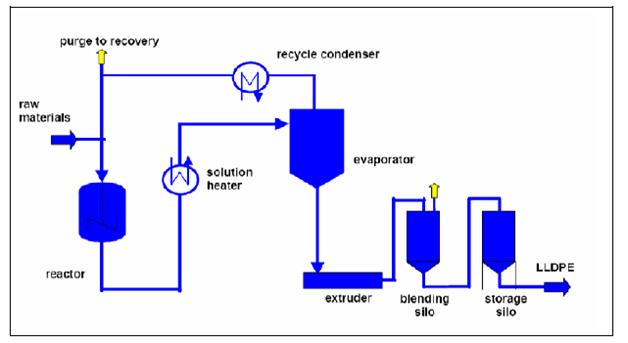

- Solution process

Figure 2: Flow diagram showing the LLDPE solution process

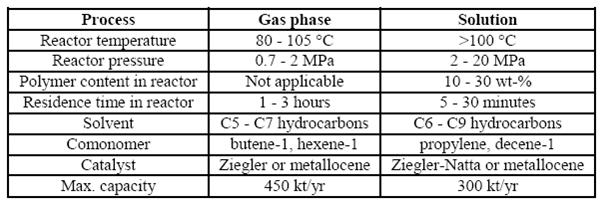

3 Technical parameters

Table 1: Technical parameters of LLDPE

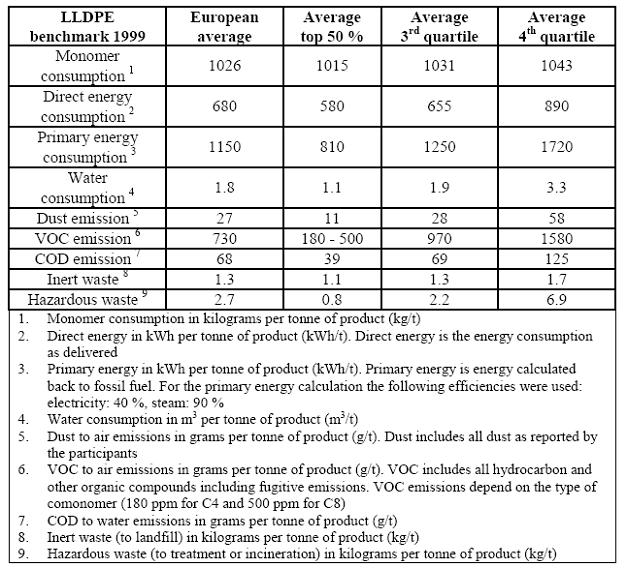

4 Emission and consumption data of LLDPE plants

Table 3: Emission and consumption data of LLDPE plants

5 Competitive technologies and energy saving potentials for the production of PE

- Solvent and comonomer selection for PE processes

Description

A solvent is needed as the carrier for catalyst or initiator feeds or as the reactor diluent for the solution and slurry suspension processes, while a comonomer is used to control the polymer density of the final product. In principle, the more volatile the hydrocarbon solvent and comonomer, the easier the separation from the polymer will be. However, there are some practical limitations:

- comonomer selection – comonomer selection is dictated by product design, desired application properties and targeted product value

- solvent selection for the LLDPE solution process – typically, the solution process is used to make higher value LLDPE grades through the application of hexene-1 or octene-1 as the comonomer. These comonomers are compatible with the hydrocarbon solvents, typically in the range of C6 to C9, used in the reactor system. Lower boiling comonomers and/or solvents are, in principle, possible, but might require a higher reactor operating pressure and thus more energy, to avoid phase separation and to maintain single phase conditions

- solvent and comonomer selection for the LLDPE gas phase process – the use of butene-1 as the comonomer results in very low residual hydrocarbon levels in the polymer fed to the extrusion section. However the use of hexene-1 as the comonomer (to improve product value) and/or the use of a condensable solvent (to improve plant productivity and energy consumption) will increase the residual hydrocarbon content

- solvent selection for the slurry HDPE suspension process – in principle, the more volatile the suspension solvent is the easier the removal, however low boiling solvents require a more complex condensing/recovery system. Furthermore, plant design (unit operations and design pressure) can prevent the application of low boiling solvents in the range of C4 to C6

- solvent selection for the high pressure polyethylene process – solvents are used as a carrier for the initiator in order to facilitate stable injection of the applied initiator. In principle, two types of solvents can be used in the high pressure polyethylene process, namely lower boiling hydrocarbon solvents in the range of C7 to C9 and higher boiling solvents in the range of C10 to C12. A lower boiling solvent will facilitate removal from the product, but leads to higher levels building up in the ethylene recycling systems. A higher boiling solvent is more difficult to remove from the polymer, but is easier to condense in the recycling streams and will thus lead to lower levels in the recycling systems. The net effect on the residual solvent level might be neutral. Good practice in the high pressure polyethylene process is to minimise the usage of hydrocarbon solvents while maintaining a stable injection of the initiators to the reactor system. Larger scale operations help to reduce the unit solvent consumption and also the residual solvent level in polymer.

Achieved environmental benefits

Low boiling solvents and suspension agents can be removed more easily and with less consumption of energy from the product leading to a reduction of VOC emissions from the storage.

Cross-media effects

No further information submitted.

Operational data

No further information submitted.

Applicability

As described. For some speciality products, such as PP for capacitor films, less volatile diluents are used to guarantee the product quality.

Economics

No further information submitted.

Driving force for implementation

No further information submitted.

- Devolatilisation during the extrusion step for LDPE and LLDPE processes

Description

This technique, also called extruder degassing, is applied to remove residual hydrocarbon components in those processes in which the product is extruded starting from the melted form, for instance solution LLDPE and high pressure LDPE. This technique requires an extended extruder since the polymer needs to be compressed, vacuum devolatilised and then compressed again for the final pelletising step. The hydrocarbon vapours coming from the vacuum dome are processed in a vacuum/scrubber system. The non-condensable substances, mainly ethylene, are sent to a flare, due to the risk of undesirable contamination with oxygen. Devolatilisation extrusion, while capable of delivering low volatiles, requires a properly designed system with respect to screw design, control loops and prevention of oxygen leaks. In order to maintain availability or product quality similar to extruders without devolatilisation, attention has to be given to avoid oxygen intrusion and fouling of the degassing dome. Proper extruder layout and design is needed to allow operation of devolatilising extruders similar to extruders without degassing.

Achieved environmental benefits

- reduction of VOC emissions from the dryer and blending/storage silos. For example, the VOC content of a solution LLDPE with 10 – 15 % of solvent is reduced to 500 ppm by devolatilisation extrusion

- consumption reduction of resources (monomer, catalyst and fuel as well as electricity).

Cross-media effects

- extruder devolatilisation allows silo venting without post treatment of the purge flow

- extruder devolatilisation avoids the use of additional fuel for thermal post treatment of low loaded purge flows

- venting time in the silos can be reduced to about 20 to 30 % of the normal time or in certain cases venting can be avoided completely

- general plant safety downstream the devolatilisation extruder is increased

- comonomers and solvents are collected in the vacuum system and are normally sent to an incinerator or furnace (thermal value)

- the use of the flare system will increase when line-up to a furnace is not available

- apart from the degassing of ethylene, another potential advantage of extruder degassing is the effective reduction of higher boiling hydrocarbons. Such degassed polymers produce, for example, less emissions during processing at the converters.

Product properties can be affected by gel formation which may increase through oxygen intrusion and formation of cross-linked polymer in the vacuum dome.

Operational data

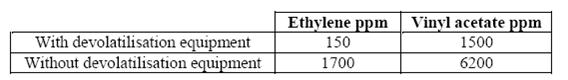

A reference plant uses two lines for producing LDPE (homopolymers as well as methacrylic acid). Both lines were converted, one at the beginning of the nineties and 1996 to be suitable for extruder degassing. The resulting volatiles are thermically utilised at a British Petroleum site. As a result of extruder degassing, the normal airing time in the silo was reduced to below 50 %. Apart from the degassing of ethylene, the main advantage of extruder degassing is the effective reduction of higher volatile hydrocarbons. Such degassed polymers produce considerably less emissions during further processing. Another plant reports monomer contents in their EVA copolymer (example given for a 28 % VA grade) with and without the use of devolatilisation equipment (see the following Table):

Table 4: Monomer content in EVA copolymer with and without the use of devolatilisation Equipment

If operational or other problems require switching off the vacuum conditions, this would lead to temporarily increased emission levels. The currently demonstrated maximum capacity of a devolatilising extruder is 250 kt/yr for homopolymer lines.

Applicability

- applicable mainly for LDPE, but also for LLDPE

- also reported to be applicable for HDPE if necessary.

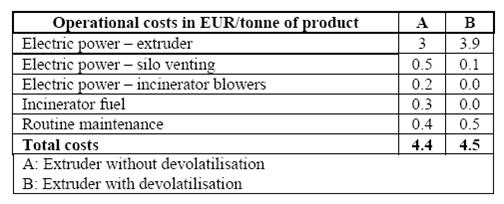

Economics

A comparison of variable operation costs for a devolatilisation extruder versus purge air treatment through a regenerative thermal oxidation unit is given in the Table below. The calculation is based on an electricity price of EUR 0.05/kWh and a fuel price of EUR 0.0162/kWh).

Table 5: Operational costs per tonne of homopolymer product (2 MFI) with (B) and without (A) devolatilisation extrusion

The cost comparison, based on variable operational costs for an LDPE homopolymer train, shows that devolatilisation extrusion and purge air treatment through regenerative thermal oxidation lead to similar operational costs. Compared to a normal extruder with a length of 12 D (D = diameter of screw) a degassing extruder needs an additional 8 D length to house the degassing section. The additional foot print required makes it difficult to retrofit existing production lines due to space limitations. For polymer modification by a chemical reaction, the devolatilisation extruder can provide mixing capabilities to disperse additives as well as the capability to remove unwanted byproducts occuring with the reaction. With a conventional extruder, a second step would be required for this process, which then adds significant costs of about EUR 0.40/kg.

Driving force for implementation

Economic and environmental reasons, such as:

- efficient reduction of residual monomer, comonomers and solvents in the product

- less emissions during further processing at the converter.

Increase of the polymer concentration in the reactor system to the maximum possible

Description

By increasing the concentration of the polymer in the reactor, the overall energy efficiency of the production process is optimised as follows:

- high pressure polyethylene process – in the high pressure polyethylene process this is achieved by maximising heat transfer. However, the properties of the product and the concentration of the polymer in the reactor are interdependent. The desired product quality imposes, therefore, a limitation to the maximum ethylene conversion level possible

- solution processes – the maximum polymer concentration in the solution process is a function of maximum temperature capability of the catalyst system, heat removal capability and maximum allowable process viscosity

- gas phase processes – in principle, there is no limitation as long as fluidised conditions and homogeneous temperature conditions are maintained in the reactor system. The recycling energy is reduced by improving heat removal by the addition of a condensable solvent and/or comonomer in the reactor system (so called ‘condensation mode’)

- HDPE slurry suspension process – the maximum viscosity of the slurry limits the maximum concentration of polymer solids in the hydrocarbon diluent. The slurry has to be maintained transportable. Depending on particle size distribution this means that typically the solid concentration has to be maintained between 30 and 35 vol-%.

Achieved environmental benefits

Increase of energy efficiency.

Cross-media effects

No further information submitted.

Operational data

No further information submitted.

Applicability

No further information submitted.

Economics

No further information submitted.

Driving force for implementation

Economic and environmental reasons.

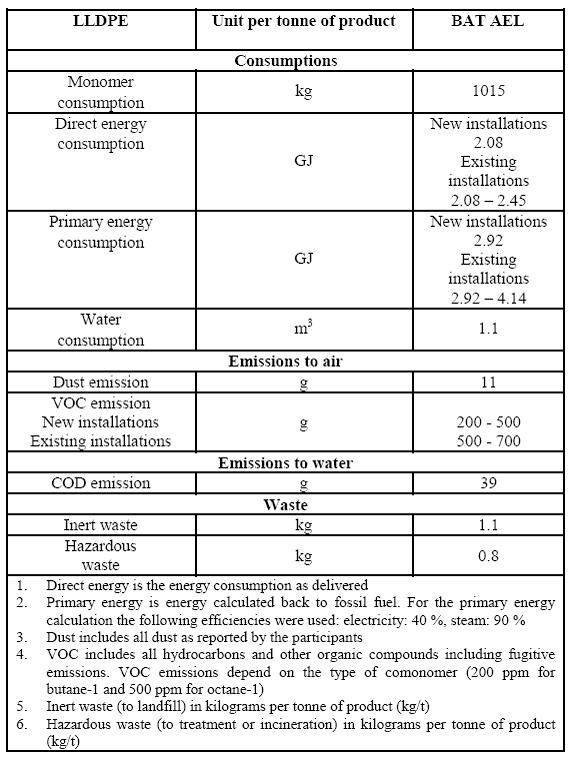

6 Emission and consumption levels associated with BAT for the production of polyolefines

Table 6: BAT associated emission and consumption levels (BAT AEL) for the production of LLDPE

Literature: BAT for Polymers, October 2006

Back to Information about polyolefins