Pasteurization in food industry

Back to EFFICIENCY FINDER

1. OBJECTIVE

Heat treatment of products is one of the main techniques in the food industry for food conservation. Heat treatment stops bacterial and enzyme activity; thus preventing a loss of quality and keeping food non-perishable. Pasteurisation is a controlled heating process used to eliminate any dangerous pathogens that may be present in milk, fruit-based drinks, some meat products, and other foods which are commonly subjected to this treatment. Pasteurization inactivates most viable vegetative forms of micro-organisms but not heat-resistant spores. As well as the application to inactivate bacteria, pasteurization may be considered in relation to enzymes present in the food, which can be inactivated by heat (BAT in the Food, Drink and Milk Industries, June 2005).

2. FIELD OF APPLICATION

Pasteurisation is used to treat all types of food products. These include milk, juices, beer and many others (BAT in the Food, Drink and Milk Industries, June 2005):

3. DESCRIPTION OF TECHNIQUES, METHODS AND EQUIPMENT

- Principal of pasteurization

- (BAT in the Food, Drink and Milk Industries, June 2005)

Both pasteurisation and blanching are based on the use of the minimum heat requirement needed to deactivate specific micro-organisms or enzymes, thus minimising any quality changes in the foods themselves [87, Ullmann, 2001]. In pasteurisation, generally a heating temperature below 100 °C is applied.

- Temperature and contact time in pasteurization

- (BAT in the Food, Drink and Milk Industries, June 2005)

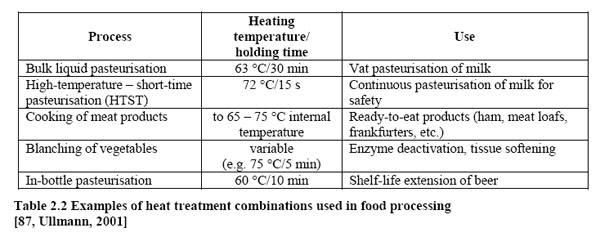

In heat treatment processes, various time/temperature combinations can be applied, depending on the product properties and shelf-life requirements. Pasteurisation temperatures commonly range from 62 to 90°C, and pasteurisation times vary from seconds to minutes.

- Batch wise pasteurization: 62 – 65°C, up to 30min

- High temperature short time (HTST) pasteurisation: 72 – 75°C, 15 - 240sec

- High heat short time pasteurisation (HHST): 85 – 90oC, 1 - 25sec

- Batch pasteurization equipment

- (Operations in Food Processing - the Web Edition, R. L. EARLE, 1983)

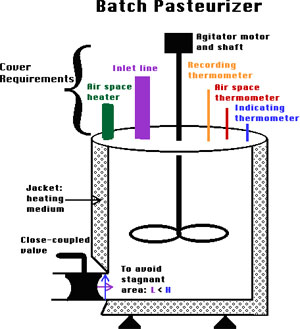

Batch wise pasteurisation is carried out in agitated vessels. The batch method uses a vat pasteurizer which consists of a jacketed vat surrounded by either circulating water, steam or heating coils of water or steam.

Figure 1: Batch pasteurizer LITERATURE: http://www.foodsci.uoguelph.ca/dairyedu/home.html

- Continuous pasteurization

- (Operations in Food Processing - the Web Edition, R. L. EARLE, 1983)

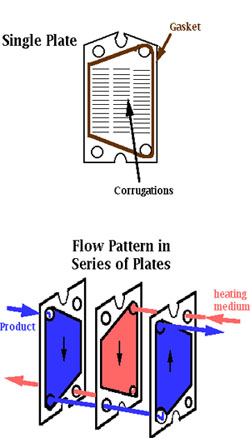

Continuous process method has several advantages over the vat method, the most important being time and energy saving. For most continuous processing, a high temperature short time (HTST) pasteurizer is used. The heat treatment is accomplished using flow-through heat exchangers (tubular, plate and frame) are with heating, holding and cooling sections. A plate heat exchanger consists of a stack of corrugated stainless steel plates clamped together in a frame. There are several flow patterns that can be used. Gaskets are used to define the boundaries of the channels and to prevent leakage. The heating medium can be vacuum steam or hot water.

Figure 2: Continuous pasteurization LITERATURE: http://www.foodsci.uoguelph.ca/dairyedu/home.html

4. COMPETITIVE TECHNOLOGIES AND ENERGY SAVING POTENTIALS

- a) Changes in the process

- Use of continuous pasteurizers: (BAT in the Food, Drink and Milk Industries, June 2005)

- In continuous pasteurization, flow-through heat exchangers, e.g. tubular, plate and frame, are used. These have heating, holding and cooling sections. To reduce energy consumption and waste water generation, continuous pasteurizers are used instead of batch ones. Continuous pasteurizers can widely be used in dairies.

- Provision of in-line storage tanks to minimize product recirculation in pasteurizers: (BAT in the Food, Drink and Milk Industries, June 2005)

- In the case of a dairy, if the capacity of in-line storage tanks is too small compared to the output of the pasteurizer in a pasteurization line, the milk has to be re-circulated in the pasteurizer several times during the day. This consumes energy and harms the quality of the product. Furthermore, longer interruptions increase the frequency of cleaning the pasteurizer. :Interruptions in the line and recirculation of the milk in the pasteurizer can be avoided or minimized by adapting the size/number of in-line storage tanks to the output of the pasteurizer and by optimizing the product change-overs.

- In this way, energy is saved mainly in the form of reduced cooling water consumption. The total consumption of electrical power required for the running of pumps, homogenizer and centrifugal separator also decreases, as the total processing time becomes shorter. Reductions in cleaning frequencies reduce the consumption of energy, water and chemicals. The negative effect of excess heat treatment on the quality of the product is also reduced.

- Membrane processes: (BAT in the Food, Drink and Milk Industries, June 2005)

- Cross-flow microfiltration (CMF) can be used in the dairy industry to remove bacteria from skimmed milk.

- High hydrostatic pressure pasteurization: (Northwest Food Processors Association:

- High Pressure Processing (HPP) is a method of food processing where food is subjected to elevated pressures (up to 87,000 pounds per square inch or approximately 6,000 atmospheres), with or without the addition of heat, to achieve microbial inactivation or to alter the food attributes in order to achieve consumer-desired qualities. Pressure inactivates most vegetative bacteria at pressures above 60,000 pounds per square inch. HPP retains food quality, maintains natural freshness, and extends microbiological shelf life. The process is also known as high hydrostatic pressure processing (HHP) and ultra high-pressure processing (UHP) (Ramaswamy et al. 2004)

- According to Wardrop Engineering (1997), this process has been commercialized in Japan for raw foods (e.g. jams and jellies) and has significant potential for fluid milk and milk products such as cheese. It is said to reduce thermal requirements, but may not deactivate naturally present degenerative enzymes.

- Electron beam pasteurization: (Northwest Food Processors Association:

- Radiation pasteurization entails subjecting food to controlled amounts of ionizing radiation that has sufficient energy to knock electrons from the outer rings of atoms of the foods to create free radicals and ions, resulting in the destruction of bacteria and pathogens. The radiation used does not have sufficient energy to split atoms that would cause the exposed objects to become radioactive.

- Electron beam technology has perhaps the greatest potential for the safe, effective, and cost-efficient radiation pasteurization of meat, dairy, and canned goods. In electron beam systems, a multi-stage electron accelerator generates a dense beam of high-energy electrons. This beam is magnetically focused and scanned across the target, providing saturation of the food product with electrons that deposit their energy and break the chemical bonds of its atoms.

- Electron beam pasteurization competes with the other radiation treatments as an alternative to thermal pasteurization. The technology uses over 90 percent less energy than conventional pasteurization techniques.

- The greatest advantage of electron beam pasteurization is that it is quite versatile. The technology can be utilized to treat products that would normally undergo thermal treatment as well as products that cannot withstand the high temperatures of traditional pasteurization. Meat products and fresh fruits and vegetables can be irradiated to kill bacteria and molds. One of the largest market barriers that face this technology is the stigma that is associated with irradiated foods.

- According to Skerret (1997), electron beam processing currently adds an additional ten cents or so per pound of product, but demonstration facilities could soon bring about lower costs. Electron beam pasteurization techniques can be a viable option for foods that cannot withstand high temperatures, such as meats, cheeses, fruits, and vegetables. In order for this technology to truly enter the marketplace, the initial capital and installation costs will need to come down, in all but the more expensive specialty food markets.

- b) Changes in the energy distribution system

- Regenerative heat exchange in a pasteurization process: (BAT in the Food, Drink and Milk Industries, June 2005)

- Pasteurizers are normally equipped with some regenerative countercurrent flow heating sections. In dairies, the incoming milk is preheated with the hot milk leaving the pasteurization section.

- It is reported that, in an example dairy, by applying indirect heat-exchange between the after-thermal treatment product and the inlet product, the specific energy consumption can be reduced by 80%.

- Also, heat exchangers have reportedly been applied in the dairy between the inlet cold product, i.e. cold milk, and the stream coming from the extraction during vacuum expansion after UHT treatment. The specific energy consumption can be reduced by 26%.

- In older dairies, heating and cooling energy can be further reduced by replacing the old plate exchangers by more effective ones.

- c) Changes in the heat supply system

- No information is available.

Back to EFFICIENCY FINDER