Potato crisps

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about starch, potatoes & grain milled production

1. GENERAL DESCRIPTION:

- 1. General Flowsheet of potato crisps production

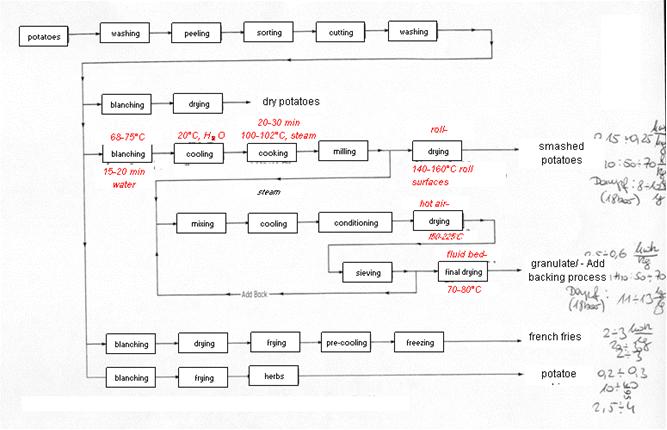

Figure 1: Production of potato crisps.

- 2. Description of techniques, methods and equipment

- (BAT for Food, Drink and Milk Industries, June 2005)

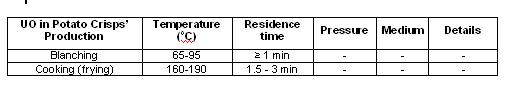

Process methods for the manufacture of crisps vary greatly, but generally take the form of washing, peeling, trimming and sorting, slicing, rinsing, partial drying, frying, salting, flavouring, cooling and packing. Potatoes are first washed with drum or flotation washers. Potatoes are elevated into washers and peeled by abrasion. Peeled potatoes are trimmed to remove eyes, bruises and decaying portions. Slicing is carried out using a series of blades mounted on a circular stationary plate and a rotating drum. Water is supplied to flash starch from the equipment. Slices potatoes are washed, usually in drum washers, to remove surface starch and sugars. Some manufacturers blanch crisps prior to frying using steam-jacketed water filled tanks. Typical blanching conditions are 65-95oC for 1min or more. After washing, surface moisture is removed by various methods including compressed air and blower fans, vibrating mesh belts and heated air. Crisp frying ay be batch or continuous. Temperatures are in the range of 160-190oC and the cooking times are typically between 1.5-3min. When the crisps leave the fryer, they are agitated to remove excess oil and discharged to a belt running underneath a salter. Flavouring may be mixed with the salt or dusted/sprayed onto the crisps in rotating drums. Finally the crisps are cooled and packed.

- 3. Temperature ranges and other parameters (table)

- (BAT for Food, Drink and Milk Industries, June 2005)

- 4. Benchmark data

2. NEW TECHNOLOGIES:

- a) Changes in the process

- b) Changes in the energy distribution system

- c) Changes in the heat supply system

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about starch, potatoes & grain milled production