Powdered milk production

Back to Information about milk products

Back to

I. GENERAL DESCRIPTION:

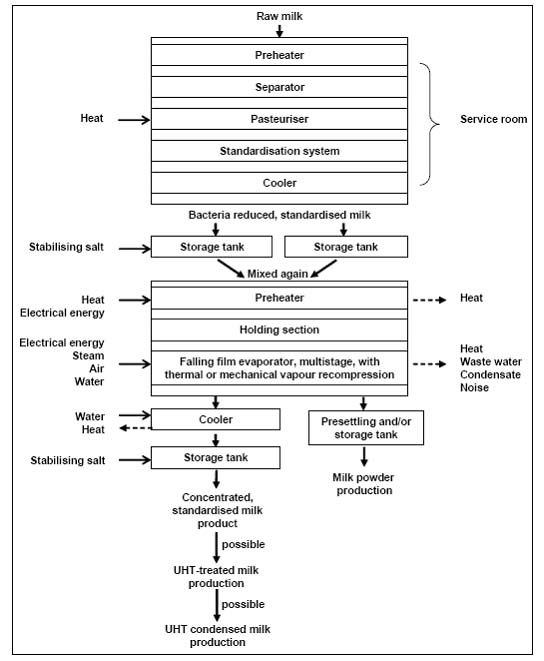

- 1. (a) General Flowsheet of condensed milk products

Figure 1: Flowsheet of processes for condensed products (e.g. UHT condensed milk) and intermediate products (e.g. milk concentrates). LITERATURE: BAT for Food, Drink and Milk Industries, June 2005

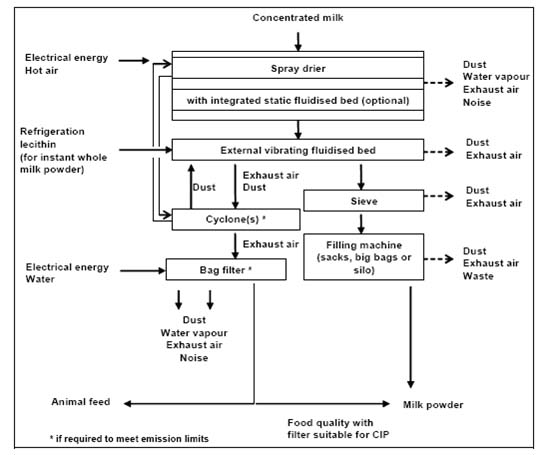

- (b) General Flowsheet of powdered milk products

Figure 2: Flowsheet of powdered milk production LITERATURE: BAT for Food, Drink and Milk Industries, June 2005

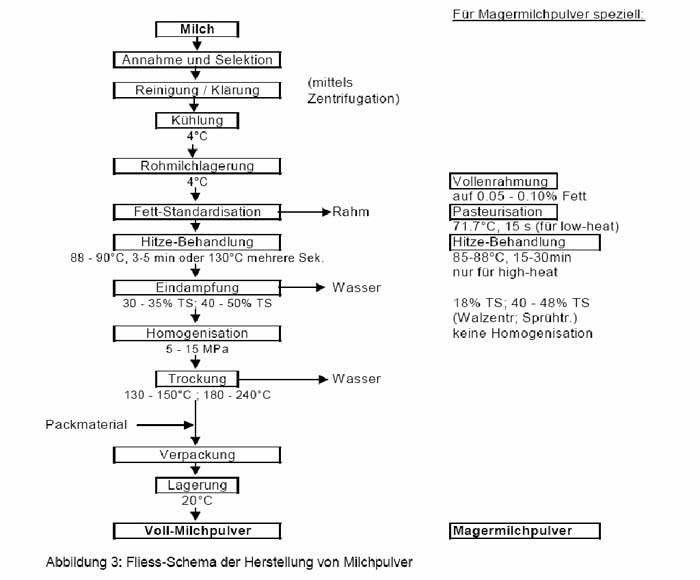

- (c) General Flowsheet and temperature levels of powdered milk production

Figure 3: Flowsheet of powdered milk production

- 2. Description of techniques, methods and equipment

- (BAT for Food, Drink and Milk Industries, June 2005)

The first stage in the production of condensed and powdered milk is the concentration of the raw milk. Homogenized milk is usually concentrated with evaporators. Falling film evaporators are generally used followed by a drying step using a spray dryer. Doubling of the concentration of milk and whey is common. The powder is typically agglomerated to improve reconstitution. Dry whole milk is susceptible to oxidative rancidity and may be packaged in a protective atmosphere to extend its shelf-life.

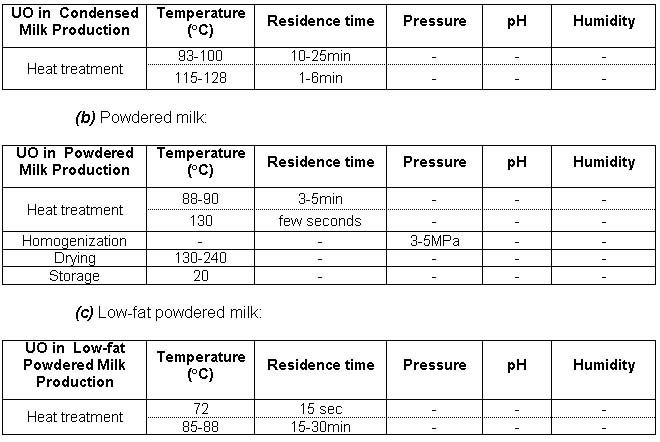

- 3. Temperature ranges and other parameters (table)

- (a) Condensed milk

- (Dairy science and Technology, University of Guelph, http://www.foodsci.uoguelph.ca/dairyedu/home.html)

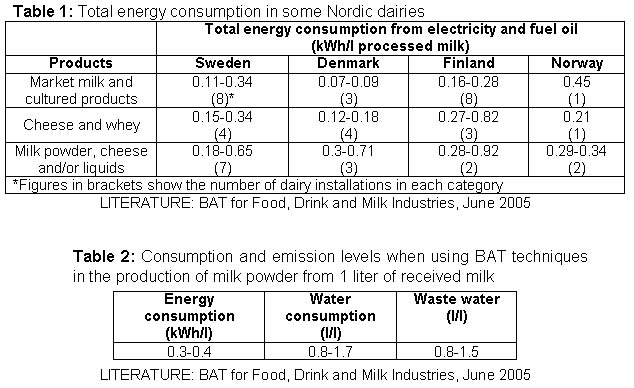

- 4. Benchmark data

II. NEW TECHNOLOGIES:

- a) Changes in the process

- Two-stage drying in milk powder production: (BAT for Food, Drink and Milk Industries, June 2005)

- a) Description of the technology:

- After the milk has been thickened from 11% to 50-60% dry matter in an evaporator, the condensed milk may further be dried to 95-97% dry matter content. Spray driers or roller driers are used in milk powder processing. Although roller driers may be found in the dairy sector and are sometimes useful for specialized products, spray driers with downstream or integrated FBD’s have become more common. This is due to their low energy usage, primarly dust-free product, and due to their reduced thermal stress.

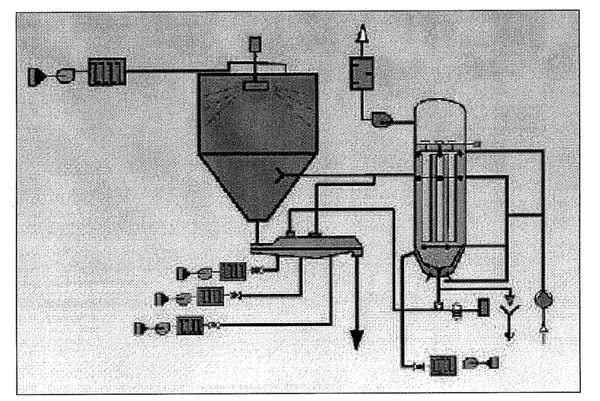

- A spray drying process using a FBD is also called two-stage drying. Figure 4 shows a two-stage drying process carried out by using a spray drier with a rotary atomizer and a separate external FBD. The outlet air is filtered by a CIP filter, which consists of a tubular filter without cyclone.

- When using two-stage drying, lower residual product moisture with less harm to product quality as well as more efficient energy utilization can be achieved. The solids leave the spray with 3-5% residual moisture. The final drying step takes place under mild conditions with low energy usage.

Figure 1: A two-stage drying process in a large dairy LITERATURE: BAT for Food, Drink and Milk Industries, June 2005

- b) Description of suitable energy supply systems:

- The two-stage drying process requires the same energy supply system with the typical drying process. Hot air is used for the heat transfer to food.

- c)Possible energy savings reachable by those measures:

- It is reported that if an integrated FBD is used, the energy consumption for drying can be reduced by approximately 20%.

- d) Economic evaluations:

- Investment involves additional capital and operational costs.

- b) Changes in the energy distribution system

No information is available.

- c) Changes in the heat supply system

No information is available.

III. SOLAR SYSTEMS INTEGRATION:

- (a) Condensed milk

Heat treatment can be achieved at temperatures either <100°C or at 130°C. In the first case, the temperature level of the process (<100°C) is easily reachable by using solar systems. In the second case, the thermal treatment process requires a temperature of 130°C. To achieve these temperatures, advanced solar collector types can be used (parabolic trough collectors) and the investment cost for the solar system may increase. Due to the fact that large amounts of hot water or steam may be required, auxiliary boilers can be used additionally to solar collectors (Joanneum Research).

- (b) Powdered milk

Heat treatment can be achieved at temperatures either 90°C or at 130°C. In the first case, the temperature level of the process (90°C) is easily reachable by using solar systems. In the second case, the thermal treatment process requires a temperature of 130°C. To achieve these temperatures, advanced solar collector types can be used (parabolic trough collectors) and the investment cost for the solar system may increase. Due to the fact that large amounts of hot water or steam may be required, auxiliary boilers can be used additionally to solar collectors. Drying is achieved by using hot air in contact with the food product. The temperatures rates required exceed the level of 130°C. Again, advanced solar collectors may be used, while auxiliary boilers can be used additionally (Joanneum Research).

- (c) Low-fat powdered milk

Heat treatment in this case requires a maximum temperature of 90°C and is easily reachable by using solar systems. Due to the fact that large amounts of hot water or steam may be required, auxiliary boilers can be used additionally to solar collectors (Joanneum Research).

Back to Information about milk products

Back to