Sweetened condensed milk production

Back to Information about milk products

Back to Evaporation for milk products

I. GENERAL DESCRIPTION:

- 1. General Flowsheet

Not available.

- 2. Description of techniques, methods and equipment

- (Dairy science and Technology, University of Guelph, http://www.foodsci.uoguelph.ca/dairyedu/home.html)

Where evaporated milk uses sterilization to extend its shelf-life, sweetened condensed milk has an extended shelf-life due to the addition of sugar. The only real heat treatment (85-90°C for several seconds) this product receives is after the raw milk has been clarified and standardized. The milk is evaporated in a manner similar to the evaporated milk. Although sugar may be added before evaporation, post evaporation addition is recommended to avoid undesirable viscosity changes during storage. Enough sugar is added so that the final concentration of sugar is approximately 45%. The sweetened evaporated milk is then cooled and lactose crystallization is induced. The milk is inoculated, or seeded, with powdered lactose crystals, then rapidly cooled while being agitated. The lactose can crystallize without the seeding but there is the danger of forming crystals that are too large. The product is packaged in smaller containers, such as cans, for retail sales and bulk containers for industrial sales.

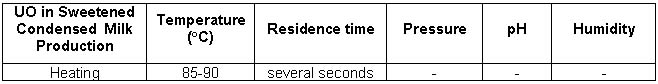

- 3. Temperature ranges and other parameters

- (Dairy science and Technology, University of Guelph, http://www.foodsci.uoguelph.ca/dairyedu/home.html)

- 4. Benchmark data

Not available.

II. NEW TECHNOLOGIES:

See information for dairies.

III. SOLAR SYSTEMS INTEGRATION:

Thermal processing of sweetened condensed milk at 90°C may require large amounts of hot water or steam. The temperature level of the process (90°C) can be reachable when using solar systems. Auxiliary boilers can be used additionally to solar collectors if large amounts of water or steam are required (Joanneum Research).

Back to Information about milk products

Back to Evaporation for milk products