Pickling in metal industry

From Efficiency Finder

Jump to navigationJump to search

Back to EFFICIENCY FINDER FOR METAL INDUSTRY

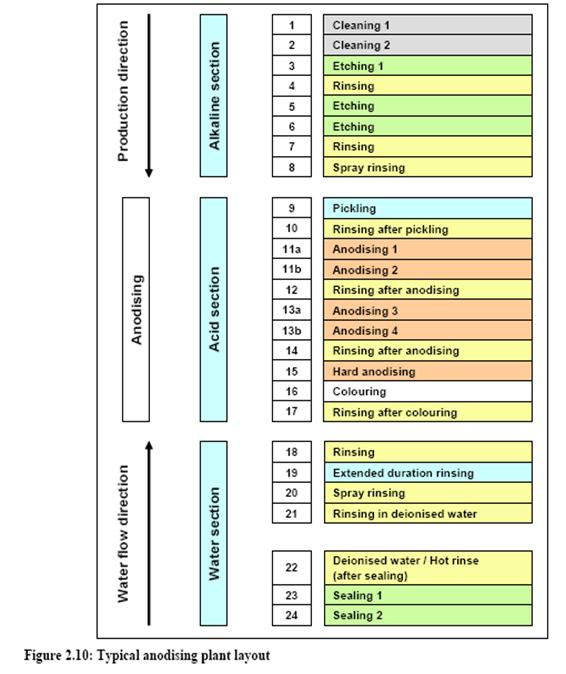

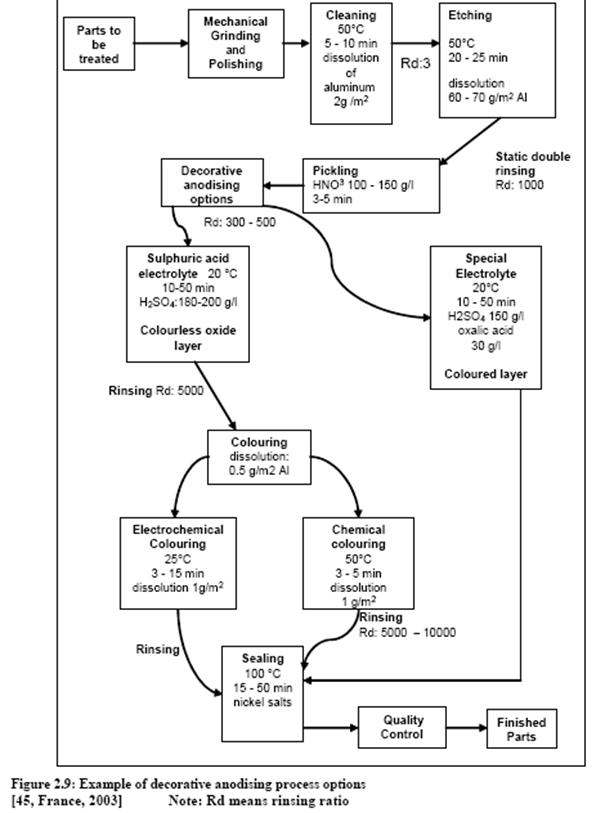

- Pickling flowsheet

Literature: BAT Surface Treatment of Metals & Plastics, 2006

- Typical parameters of the process

| Process | Temperature [°C] | Heat transfer medium | Residence time | Chemicals | Concentration | Details | Literature |

| Pickling | Acid pickling agents (hydrochloric or sulphuric acids are normally used; nitric, hydrofluoric or phosphoric acid or mixtures of acids are used in special cases; fluoride- containing solutions for realibly pickling certain alloys) | BAT for the surface treatment of metals and plastics, August 2006 | |||||

| Pickling of iron materials | ~60 | Acid agents (wetting and emulsifying agents) | sulphuric acid: 25% | Derostind and descaling of iron material | |||

| Pickling and descaling | 30-35 | Hydrochloric acids | 18-22 | ||||

| Pickling of cast iron | 35-40 | Hydrochloric acids | 20-25 | ||||

| Pickling of aluminium | Nitric acids | <150 g/l |

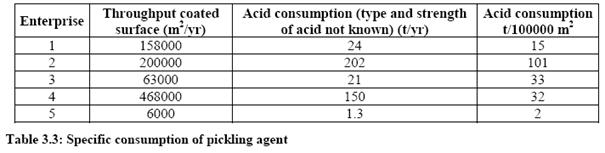

- Pickling

Literature: BAT for the Surface Treatment of Metals & Plastics, 2006

- Energy losses from the surface area of heated process solutions

Image: Pickling flowsheet5.jpg

LITERATURE: BAT for the Surface Treatment of Metals and Plastics, May 2005