Additional information: Finishing of wool

Back to Finishing of wool

1. DESCRIPTION OF TECHNIQUES, METHODS AND EQUIPMENT

- FINISHING OF WOOL KNITWEAR

The finishing stage is a very important and integral part in the manufacture of wool knitwear, because finishing and how well it is carried out can and does dramatically impact upon the handle, appearance and wear performance of the final knitted garment.

Generally there are three main objectives when finishing wool knitted products. These include,

- Relaxation of the knitted structure in order to release strains and tensions imposed during the spinning and knitting process. This is to minimise the potential for further relaxation so that no noticeable further shrinkage occurs during subsequent domestic laundering.

- Improving both the handle and appearance of the final knitted product thereby making it ready and attractive for sale.

- Removal of additives such as processing aids which were applied during manufacture to assist in processing e.g. Spinning lubricants. This is more important in the case of woollen spun knitwear such as Shetland and Lambswool which normally contain significant amounts of processing oil. Inadequate removal (Woolmark recommends less than 1.5% by weight Total Fatty Matter remaining), can lead to increased soiling, and the garment developing a smell during garment storage, due to the residual oil become rancid due to oxidation.

In addition to the above main objectives, finishing also provides an opportunity and a convenient point for applying added value or adding functional finishes to wool knitwear, for example; easy care, stain and shower resistance, etc.

- Typical finishing recipe (Woollen Spun Knitwear)

Generally, scouring and milling are carried out separately i.e. a two stage process, and a typical method is as follows: Scour: Set bath at 40°C Add 3-6% detergent L: R = 20-30: 1 Run 2-15 minutes (depending upon machine etc.) Drain Rinse in warm water at 40°C Mill: Set bath at 40°C Add 1-3% non-ionic detergent L: R = 20-30: 1 Run 2-40 minutes (depending upon machine etc.) Drain Rinse well

Hydro: As much water as possible should be removed in order to reduce drying time. Tumble Drying: It is important to establish a standard minimum time. Suggested: Temperature for medium to deep shades is 70-90 °C, whereas for paler shades and some mixture or multi-coloured garments, the temperature should not exceed 60 °C.

- Typical Finishing Procedure (Worsted spun wool knitwear)

Scour Set bath at 40oC 0.5-1.0 % Detergent (On weight of wool) L: R 30:1 Run 2-5 min’s Drain Rinse well Hydro-extraction As for woollen spun knitwear Tumble Drying as for woollen spun knitwear

source: 2005 Australian Wool Innovation Pty Ltd: Finishing of knitted wool (pdf)

- A general finishing procedure for woven fabrics includes

Fabric setting

Crabbing is used to relax and stabilise latent strains within the fabric that are introduced during spinning and weaving. The process is mainly applicable to worsted fabrics. If fabrics are not stabilised in this way, especially plain weave structures, they may be susceptible to the formation of distortions, such as “crowsfooting” or running (crease) marks during subsequent wet processes. Traditional batch crabbing involves winding the fabric on a roll that is half submerged in very hot or boiling water. The fabric winding direction is reversed to even out the processing effect. After a pre-determined time, the fabric is “shock cooled” with cold water to promote good setting. During the process crosslinks within the wool molecular structure are broken and then reformed to stabilise the fabric’s flat configuration.

Scouring and Milling

Scouring (washing) is carried out in water with addition of detergent. Synthetic detergents, mainly non-ionic and anionic, are widely used, having good stability to hard water and are easy to remove during rinsing. Rope processing is normally carried out at pH 8.0-8.5 and 40°C or slightly higher temperature for open width processing. In batch processing, the ends of the fabric are sewn together to form an endless loop, which is fed through squeeze rollers for a predetermined time, normally 30-60 min., followed by rinsing. As the fabric passes through the nip rollers, scouring liquor is squeezed from the fabric promoting cleaning and liquor interchange but also “working” the wool fibre, to develop handle. The fabric is then allowed to “relax” without tension as it collects in the bottom of the machine, before it is lifted to pass again through the nip rollers. Modern batch scouring machines operate at high speeds (200 –250m/min) to minimise processing time but also to ensure good opening and movement of fabric to reduce the propensity for creasing. Water fans or jets, usually situated before the nip, help to open out the fabric for uniformity of processing. In modern multiple rope machines, individual channel control ensures even finish piece to piece, allowing for variation in fabric lengths. Rapid rope scouring machines operate at higher speed, impacting the fabric against a baffle plate or device, to generate handle and are particularly suitable for blends. For lightweight fabrics, which may crease if scoured in rope batch machines, open width scouring processing is used. This may be a batch or continuous process. During scouring the fabrics are normally sprayed with scouring liquor, followed by nip rollers or vacuum slots to remove liquor but little effect on handle is achieved and a cool, clear finish is retained. New developments in solvent scouring allow continuous cleaning with negligible emissions and almost total recycling of solvent. This provides a good preparation, particularly for blends. The procedure is applicable to elastane-containing fabrics. Milling normally follows rope scouring and is used to further develop fabric cover and bulk, particularly for flannels and also woollen fabrics. During milling the liquor is much reduced to that used for scouring and detergent levels are increased. The fabric is passed through a milling box or trough, into which it is compressed by rollers. As the fabric is passed through the milling box, the lid or sides of the milling box are tapered so as to restrict the passage of the fabric. This action promotes length shrinkage (felting) of the fabric, generating more bulk, density and cover than possible by scouring alone. In woollen fabrics the initial base weave is almost entirely obscured during milling. The process also adds strength and density to the fabric by the interfibre felting, providing a suitable base for woollen fabrics, which are to be subsequently raised. Piece dyeing would follow scouring or milling for pieced dye fabrics.

Carbonising

Carbonising is a process to remove residual vegetable matter. The fabric is usually treated with sulphuric acid followed by drying to concentrate the acid and baking to break down cellulosic impurities. These become brittle and are removed by beating or dry milling. Carbonising is usually carried out after milling, but its position in the finishing procedure varies. New developments in carbonising include solvent processing, for which reduced wool damage is claimed. Carbonising is mainly applicable to woollen fabrics, because vegetable matter is not completely removed in the woollen spinning process.

Drying

Drying is carried out on the stenter. Stenters utilise hot air currents blowing over the fabric as it passes through drying chambers. The fabric is held at the edges in an open and flat condition by pins or clips located on endless chains. Drying temperatures are normally 120- 140°C, with lower values for white or pastel shades to minimise yellowing. Wool fabrics should be dried close to their relaxed dimensions. Width and overfeed settings provide the necessary control of dimensions. Over-drying is not good for fabric quality and drying to excessive dimensions can give problems with fabric stability in later processing. Advances, in stenter design have been optimisation of airflow to produce uniform temperature across and along the fabric. Pyrometers are fitted to control temperatures and moisture meters control the degree of drying. Heat recovery units and gaseous emission control are environmental additions to drying lines. Drying on large, heated metal cylinders “can drying” may be used between some of the finishing processes, e.g. after open width scouring, but has no control over fabric dimensions and can induce length tension.

Raising

Raising is mainly applicable to woollen fabrics and is a process that develops nap (pile or cover) on the surface of the fabric, obscuring the base weave structure. The fabric is passed tangentially over rotating cylinders, wrapped with raising wires. These cylinders are fixed around a large rotating drum. By modifying rotating speeds, directions, wire type, fabric speed etc., a variety of raised finishes can be achieved. The fabric can be processed wet or dry, in upright or laid pile direction. Emphasis in machinery design has been to optimise control of the above parameters, but also absolute control of fabric tension throughout the raising operation, which is critical to uniformity of finish. Raising machines are often double drum, with one drum above another to reduce floor space. Machines are designed for easy access and quick change of cylinders for different finishes, including sueding. Shearing machines are often incorporated into raising lines, to ensure an even pile during processing.

Shearing (Cropping)

Shearing is a procedure to remove surface fibres, because excessive surface fibre can present problems with pilling and loss of garment appearance in wear. During shearing the fabric passes through a series of tension bars and over an angled shearing bed. The prominent fibres are cut by blades, wound helically around a rotating cylinder against a stationery blade. Strong suction removes cut fibres. Oiled felts resting against the cylinder help to lubricate it and reduce operating temperatures. Shearing machines are often in trains of 2 or 3 (or more) heads for back and face cutting in a single pass. Piano beds allow for bulky edges and automatic seam detectors allow passage of fabric joins without damage. Together with shearing, singeing is often used to control surface fibre, particularly for blends. During singeing, surface fibres are removed by an intensive flame or by reflected heat. Singeing is more invasive then shearing and penetrates deeper into the fabric than is possible by shearing, which is limited by fabric surface topography.

Relaxation and Pressing

Continuous steam relaxation tables are used to relax processing strains remaining in the fabric. The fabric is steamed on a continuously moving belt (usually with vibration and overfeed) to promote shrinkage. It is then shock cooled. Modern developments include enclosed hoods to maximise, control and intensify the steaming operation, reducing actual steam use and costs in comparison with traditional open tables. Steam relaxation tables are an integral part of relaxing and finishing elastane containing fabrics. Pressing machines are mainly used to prepare fabrics for pressure decatising. Recent developments use the passage of fabric around a small heated cylinder, pressed against it by an impermeable belt. Belt and cylinder are driven and synchronisation of speeds permits minimum tension pressing. The fabric is pre-wetted to promote pressing efficiency. Continuous decatising machinery is also available for pressing and passes the fabric around a large heated cylinder, either wetted or steamed, pressed against it by a belt or wrapper. This type of machinery however, is more usually used to provide more versatility regarding fabric aesthetics, uniformity of finish and dimensional properties and is often used in conjunction with pressure decatising, A new machinery development in continuous decatising uses belts, totally sealed at the edges, to transport the fabric. As steam cannot escape, it produces more intensified conditions (and higher levels of set) than possible in other continuous machinery. The machine has found particular application for wool/polyester blends.

Pressure Decatising

This is a batch process that provides conditions to achieve high levels of set. The principal objectives of the process are to produce a permanent pressed finish with good handle, desired lustre and dimensional stability for making up. The process involves winding the fabric onto a large perforated cylinder/beam, interleaved with a wrapper fabric. Steaming is carried out in a sealed chamber under pressure. Typical conditions are 1.0 Bar (120°C) but conditions vary with quality. Different steam flow directions are possible, e.g. in-out or visa versa and with different steam pressures, cooling procedures and wrapper types. A range of finishes and handle variations is therefore achievable. Modern pressure decatising machines generally allow loading, unloading and processing concurrently, giving high production. Cylinders are much larger than traditional machines, allowing for increased loads, more uniform steaming and minimise end marking. This is important for reproducibility of finish. Absolute control of wrapper tension and axial movement during winding (loading) reduces problems of wrapper collapse and bulky edges to the batch.

source: 2005 Australian Wool Innovation Pty Ltd: finishing of woven wool

2. NEW TECHNOLOGIES

- a) Changes in the process

1.) Enzyme catalysed finishing treatment:

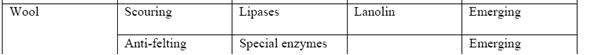

Main enzymatic processes already in use or currently emerging in the textile sector for wool:

2.) Reduction of water consumption

Energy consumption in textile industry often goes along with water consumption, because water is heated up in a large scale for the process baths.

The following specific water consumption levels are considered achievable using certain measures:

- finishing of woven fabric consisting mainly of wool: …………… < 200 l/kg

- finishing of woven fabric consisting mainly of wool (for processes that require high liquor ratio) ………………………………………………………….. < 250 l/kg

For information on water saving measures, see “Finishing” in general.

source: BAT in textile industry - 2003

3.) Plasma treatment

- b) Changes in the energy distribution system

No information is available.

- c) Changes in the heat supply system

No information is available.

Back to Finishing of wool