Beer

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about beer

1. GENERAL DESCRIPTION:

- 1. Definition

- (BAT in the Food, Drink and Milk Industries, June 2005)

Beer is traditionally considered to include products such as lager, e.g. Pilsner malt and Munich malt, ale, porter and stout. It is an alcoholic drink delivered from malt barley, with or without other unmalted cerial grains, and flavoured with hops. Sugar may also be added.

- 2. General Flowsheet of beer production

See the excel-sheet: Info for Beer Products.

- 3. Description of techniques, methods and equipment

- The brewing process: (BAT in the Food, Drink and Milk Industries, June 2005)

- There are three basic steps in the process: mashing, fermentation and maturation/conditioning:

- a) Mashing:

- Grains are normally received in bulk at breweries and transferred to silos. The malted barley is milled before use, and then the ground materials or grist are mashed to produce a fermentable substrate for yeast fermentation. Additives may be used as a supplementary carbohydrate source. The grist is mixed with hot water to produce a thick slurry. The mix is then held for a sufficient period to allow the enzymes present in the malt barley to break down starch and proteins in cereals. Depending on the way in which the temperature is raised, mashing processes are classified into two types, i.e. infusion or decoction mashing. With infusion mashing, the entire mash is heated up, with appropriate rests until reaching the final mashing-off temperature. In decoction mashing, the temperature is increased by removing and boiling part of the mash. By returning it back to the remainder, the temperature of the total mash is increased to the next higher rest temperature. The vessel used for mashing is known as a mash tun. The wort is separated from the brewers grain by filtration in a mash filter or by straining. This is called lautering and takes place in lauter tuns. Once the so-called first wort has run off, the water is sprayed over the spent grist to extract as much wort as possible. After completion of the lautering, the leached brewers grains are discharged to silos and traditionally sold to farmers as cattle feed.

- b) Fermentation:

- The wort is boiled for 1 to 1.5 hours in the wort kettle with hops or hop extracts, releasing bitter substances that are dissolved. The wort is boiled with a boiling intensity of 5 to 8% evaporation of casting volume per hour. A coarse coagulum of proteinaceous precipitated material is separated from the wort. This is known as the hot trub. Synthetic additives, based on polyester, result in a compact separation of unpleasant, coarse, and bitter-tasting of hot trub. The wort is clarified in a whirlpool to remove the hops and then cooled to the pitching temperature. The hot cooling water, of about 75 to 85°C, is collected and used as brewing water and for cleaning. It is possible to produce stronger wort than that corresponding to the original gravity of the final beer produced and it is possible later, before or after fermentation, to dilute it with water to the desired extract content. This is called high gravity brewing. Whether dilution is performed before or after fermentation depends, among other things, on local legislation. A further aim of wort boiling is the inctivation of all enzymes, sterilization as well as concentration of the wort. The clear hopped wort is aerated to encourage yeast propagation prior to fermentation and yeasts are added. The particular yeasts strains used are typical for beer production. To maintain the desired fermentation temperature, the tanks are cooled. At the end of fermentation, the yeast is separated from the product. A part of it is used for another batch, and a remainder is disposed of or considered to be a co-product.

- c) Maturation/conditioning:

- Lagers require conditioning by chilled storage for several weeks before clarification. The beer is generally clarified in diatomaceous earth filter, e.g. kieselguhr. After carbonation, the beer may be subjected to a number of preservation processes, such as flash pasteurization and aseptic filling, membrane separation or in-container pasteurization. Before bottling, the beer is filtered through a filter cake. Activated carbon may be used to correct a mild off-taste.

- Consumption and emission levels in breweries: (BAT in the Food, Drink and Milk Industries, June 2005)

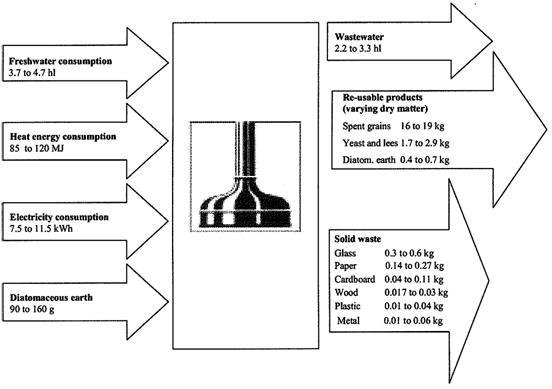

- Breweries use significant amounts of water and energy and produce waste water and solid residues. In Figure 1, the typical consumption and emission levels for german breweries are presented:

Figure 1: Input and output figures for large german breweries (capacities over 1 million hl beer) per hl of beer sold LITERATURE: BAT in the Food, Drink and Milk Industries, June 2005

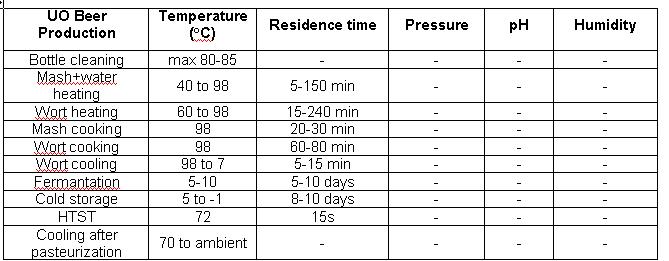

- 4. Temperature ranges and other parameters (table)

- (Murauer-case study, Joanneum Research)

- 5. Benchmark data

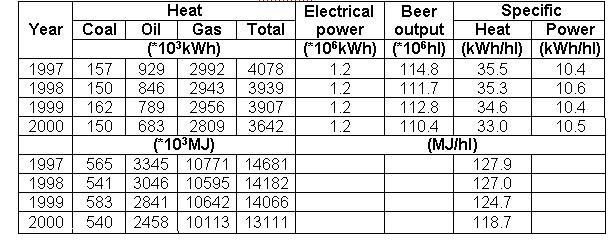

Breweries need both electrical and heat energy. Combined heat and power generation is in use in some facilities. Depending on availability, price and legal requirements, different fuels such as coal, oil or gas are used. The table below gives details on the energy, heat and electricity consumptions in some german breweries:

Table 1: Energy consumption in german breweries with more than 20 employees

LITERATURE: BAT in the Food, Drink and Milk Industries, June 2005

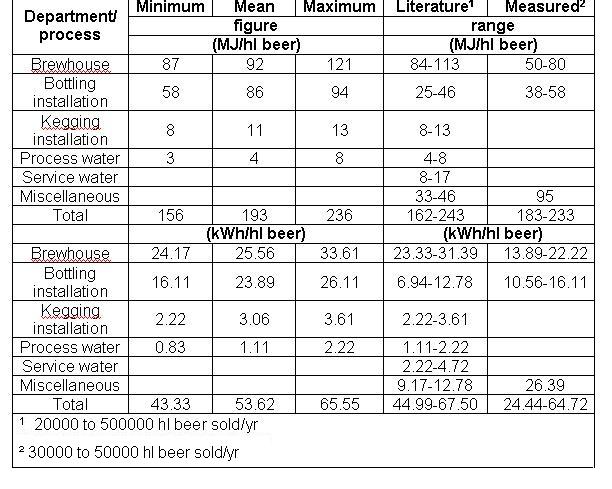

A brewery without a sophisticated heat recovery system consumes about 28.78 - 55.55 kWh/hl beer (100 – 200 MJ/hl). The main heat consuming process steps are mashing, wort boiling, generation of hot liquor, CIP, sterilizing, bottle/keg cleaning and pasteurizing. Heat consumption data are given in the following table:

Table 2: Heat consumption for different brewery processes

LITERATURE: BAT in the Food, Drink and Milk Industries, June 2005

The major consumers of electrical energy are the packaging area; cooling plant; compressed air plant; if applied, the carbon dioxide recovery plant; WWTP and air conditioning. Pumps, ventilators, drivers and electric lighting count for a large part of the electricity consumption, with about 8- -12 kWh/hl in a brewery.

2. NEW TECHNOLOGIES:

See information on breweries.

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about beer