Difference between revisions of "Berglandmilch (Austria)"

(New page: Back to EFFICIENCY FINDER FOR FOOD INDUSTRY Back to [[]] Back to Case studies 1. Case study or built example Case study 2. In...) |

|||

| (13 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

Back to [[Subsection DA food|EFFICIENCY FINDER FOR FOOD INDUSTRY]] | Back to [[Subsection DA food|EFFICIENCY FINDER FOR FOOD INDUSTRY]] | ||

| − | Back to [[]] | + | Back to [[Cleaning of bottles and cases for milk products]] |

Back to [[Case studies of food industry|Case studies]] | Back to [[Case studies of food industry|Case studies]] | ||

| − | |||

| + | ;1. Case study or built example: | ||

| − | 2. Industry Sector | + | ;2. Industry Sector |

Dairy | Dairy | ||

| − | 3. Industrial application | + | ;3. Industrial application |

Process-water heating and integration in a central warm-water store | Process-water heating and integration in a central warm-water store | ||

| − | |||

| − | + | ;4. Process description | |

| − | Image:Process description-Berglandmilch (Austria).jpg | + | * Process flowsheet: |

| + | |||

| + | |||

| + | [[Image:Process description-Berglandmilch (Austria).jpg]] | ||

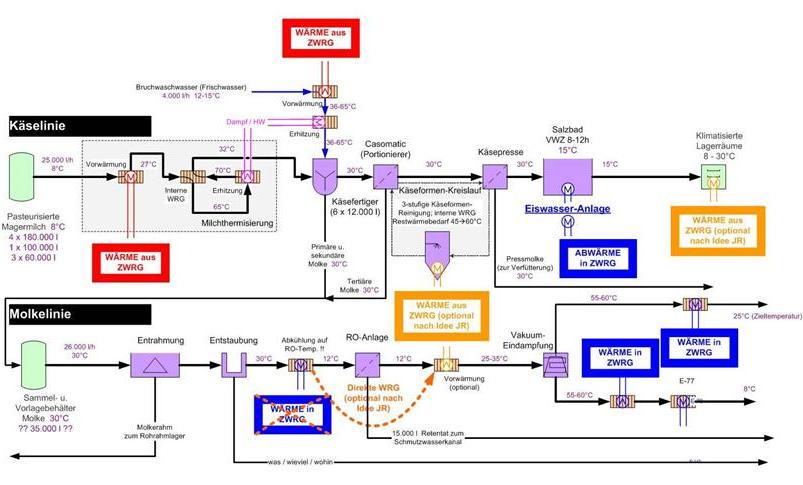

Fig: Flowsheet of the “Berglandmilch” dairy | Fig: Flowsheet of the “Berglandmilch” dairy | ||

| − | + | * Processes: | |

Berglandmilch produces different kinds of cheese in this factory. Milk, water and fermentation cultures (rennet, lactic bacteria, molds etc.) are put into the vat. The casein in the milk coagulates. During and after coagulation the curdled paste is cut with rotating knives in order to obtain smaller or larger pieces. In this phase of the production process the whey is removed. The curdled cheese is pressed into forms, excess whey is removed. The formed cheese is cured in salt water for a few hours and then stored in temperated warehouses until ready for sale. | Berglandmilch produces different kinds of cheese in this factory. Milk, water and fermentation cultures (rennet, lactic bacteria, molds etc.) are put into the vat. The casein in the milk coagulates. During and after coagulation the curdled paste is cut with rotating knives in order to obtain smaller or larger pieces. In this phase of the production process the whey is removed. The curdled cheese is pressed into forms, excess whey is removed. The formed cheese is cured in salt water for a few hours and then stored in temperated warehouses until ready for sale. | ||

| Line 37: | Line 39: | ||

| − | Image:Processes with thermal energy demand.jpg | + | [[Image:Processes with thermal energy demand.jpg]] |

| − | 5. Energy flows and temperature ranges | + | ;5. Energy flows and temperature ranges |

| − | + | ||

| + | * Main heat supply system and fuel: | ||

No information is available. | No information is available. | ||

| − | + | ||

| + | * Energy consumption (Sankey): | ||

No information is available. | No information is available. | ||

| − | + | ||

| + | * Temperature ranges and other parameters: | ||

No information is available. | No information is available. | ||

| − | 6. Solar Thermal Plant | + | ;6. Solar Thermal Plant |

| − | + | ||

| + | * Used scheme: | ||

No information is available. | No information is available. | ||

| − | + | ||

| + | * Description of the main features and components: | ||

No information is available. | No information is available. | ||

| − | + | ||

| + | * Pictures of the built solar system: | ||

No information available. | No information available. | ||

| − | 7. Energy savings | + | ;7. Energy savings |

| − | + | ||

| + | * Pinch analysis results: | ||

The pinch temperature is low, about 295 K, 22°C. Additional heating with solar thermal energy does not introduce additional energy below the pinch temperature, where it would only lead to an additional cooling demand. With the possibilities for heat exchanger placement (place, piping length etc.) in this factory and following the placement rules of the pinch theory a possible heat exchanger network is calculated (see figure xxx). | The pinch temperature is low, about 295 K, 22°C. Additional heating with solar thermal energy does not introduce additional energy below the pinch temperature, where it would only lead to an additional cooling demand. With the possibilities for heat exchanger placement (place, piping length etc.) in this factory and following the placement rules of the pinch theory a possible heat exchanger network is calculated (see figure xxx). | ||

| − | Image:Energy savings-Berglandmilch (Austria).jpg | + | [[Image:Energy savings-Berglandmilch (Austria).jpg]] |

As can be seen stream 1 in figure above, stream 4 in table xxx needs additional heating. This heating could be done by solar thermal energy. | As can be seen stream 1 in figure above, stream 4 in table xxx needs additional heating. This heating could be done by solar thermal energy. | ||

| − | + | * Energy savings: | |

No information is available. | No information is available. | ||

| − | 8. Economic evaluation | + | ;8. Economic evaluation |

| − | |||

| + | * Economic parameters of the built solar system: | ||

| − | |||

| + | [[Image:Economic evaluation-Berglandmilch (Austria).jpg]] | ||

| − | |||

| + | [[Image:Economic evaluation-Berglandmilch (Austria)2.jpg]] | ||

| − | Image:Economic evaluation-Berglandmilch (Austria)3.jpg | + | |

| + | [[Image:Economic evaluation-Berglandmilch (Austria)3.jpg]] | ||

Literature: Joanneum Research Graz, Austria | Literature: Joanneum Research Graz, Austria | ||

| + | |||

| + | |||

| + | |||

| + | Back to [[Subsection DA food|EFFICIENCY FINDER FOR FOOD INDUSTRY]] | ||

| + | |||

| + | Back to [[Cleaning of bottles and cases for milk products]] | ||

| + | |||

| + | Back to [[Case studies of food industry|Case studies]] | ||

Latest revision as of 18:09, 28 November 2014

Back to EFFICIENCY FINDER FOR FOOD INDUSTRY

Back to Cleaning of bottles and cases for milk products

Back to Case studies

- 1. Case study or built example

- 2. Industry Sector

Dairy

- 3. Industrial application

Process-water heating and integration in a central warm-water store

- 4. Process description

- Process flowsheet:

Fig: Flowsheet of the “Berglandmilch” dairy

- Processes:

Berglandmilch produces different kinds of cheese in this factory. Milk, water and fermentation cultures (rennet, lactic bacteria, molds etc.) are put into the vat. The casein in the milk coagulates. During and after coagulation the curdled paste is cut with rotating knives in order to obtain smaller or larger pieces. In this phase of the production process the whey is removed. The curdled cheese is pressed into forms, excess whey is removed. The formed cheese is cured in salt water for a few hours and then stored in temperated warehouses until ready for sale.

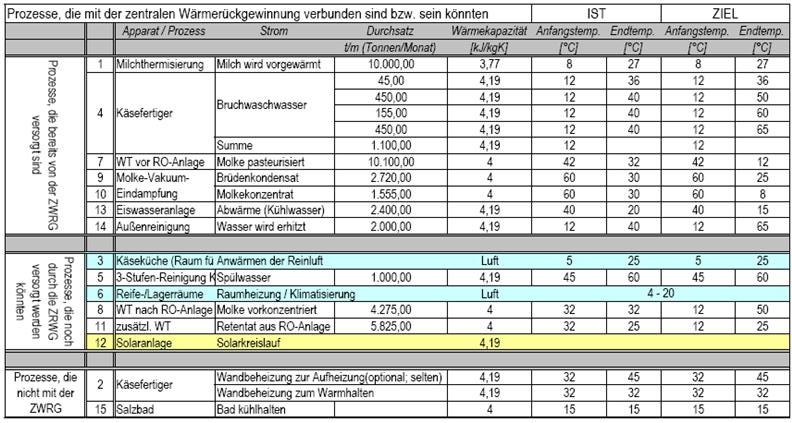

Processes with thermal energy demand

- 5. Energy flows and temperature ranges

- Main heat supply system and fuel:

No information is available.

- Energy consumption (Sankey):

No information is available.

- Temperature ranges and other parameters:

No information is available.

- 6. Solar Thermal Plant

- Used scheme:

No information is available.

- Description of the main features and components:

No information is available.

- Pictures of the built solar system:

No information available.

- 7. Energy savings

- Pinch analysis results:

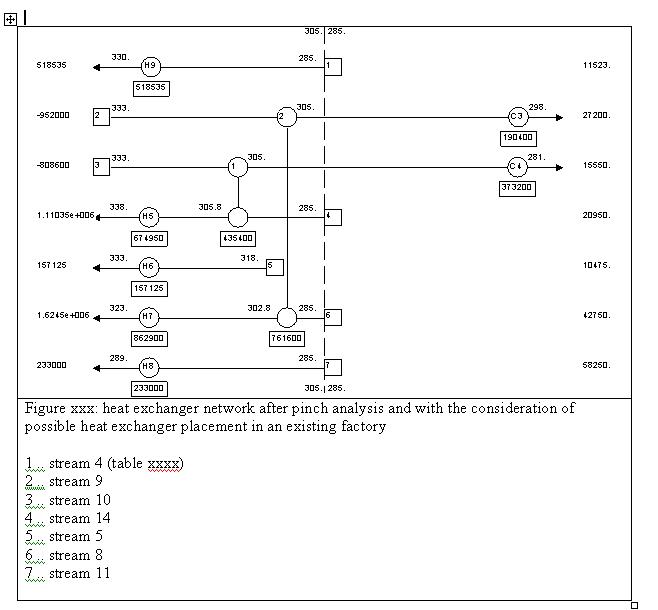

The pinch temperature is low, about 295 K, 22°C. Additional heating with solar thermal energy does not introduce additional energy below the pinch temperature, where it would only lead to an additional cooling demand. With the possibilities for heat exchanger placement (place, piping length etc.) in this factory and following the placement rules of the pinch theory a possible heat exchanger network is calculated (see figure xxx).

As can be seen stream 1 in figure above, stream 4 in table xxx needs additional heating. This heating could be done by solar thermal energy.

- Energy savings:

No information is available.

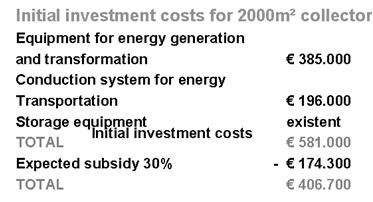

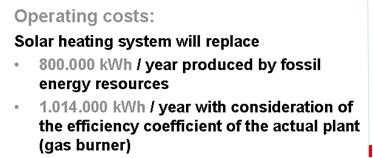

- 8. Economic evaluation

- Economic parameters of the built solar system:

Literature: Joanneum Research Graz, Austria

Back to EFFICIENCY FINDER FOR FOOD INDUSTRY

Back to Cleaning of bottles and cases for milk products

Back to Case studies