Canned meat

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about meat production

1. GENERAL DESCRIPTION:

- 1. General Flowsheet of canned meat production (beef muscle in gelatine)

- (BAT in the Food, Drink and Milk Industries, June 2005)

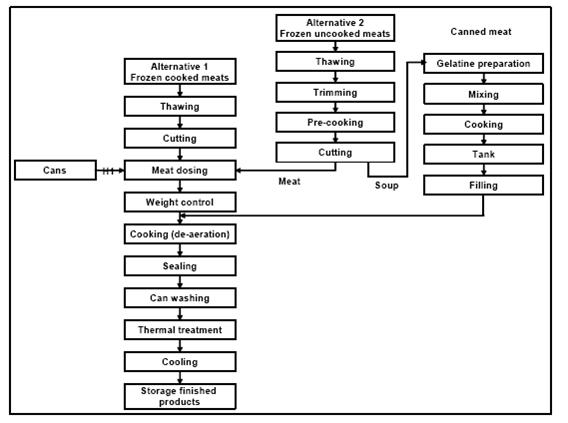

Different raw materials, such as cooked or uncooked, chilled or frozen meat may be used to produce canned meat. A general flowsheet is presented below:

Figure 1: Canned meat production. Literature: BAT in Food, Drink and Milk Industries, June 2005

- 2. Description of techniques, methods and equipment

- (BAT in the Food, Drink and Milk Industries, June 2005)

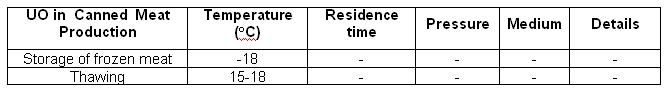

Frozen meat is generally transported in plastic bags inside a cardboard secondary packaging. Meat is stored at a temperature below -18oC. Thawing can be achieved with air at a controlled temperature, or by an intermittent shower, or by immersion into running water. The two first methods allow a reduction in the water consumption, but require longer times and larger surface areas. When thawing in a water bath, the unpacked meat is put in iron crates and completely immersed in water at 15-18oC. Gelatine is prepared from industrial powder. It may come from broth obtained during meat cooking if uncooked raw meat is used in the installation. The gelatine is de-aerated and dosed in cans by a vacuum filler already containing the required part of meat. The cans are then sealed and washed with hot water to remove meat or gelatine residuals. Cans are put in metal baskets and then sterilized in autoclaves, either in batch or continuous retorts, before being cooled. The cooled and dried cans are sent to be secondary packaged using cardboard boxes or bundles with a cardboard base and having a thermo-retractable wrap. The product has a long shelf-life and does not need special care, apart from a good aeration to avoid condensation on the cans which may damage their external surfaces.

- 3. Temperature ranges and other parameters (table)

- (BAT in the Food, Drink and Milk Industries, June 2005)

- 4. Benchmark data (from BAT or from other sources) such as

- (BAT in the Food, Drink and Milk Industries, June 2005)

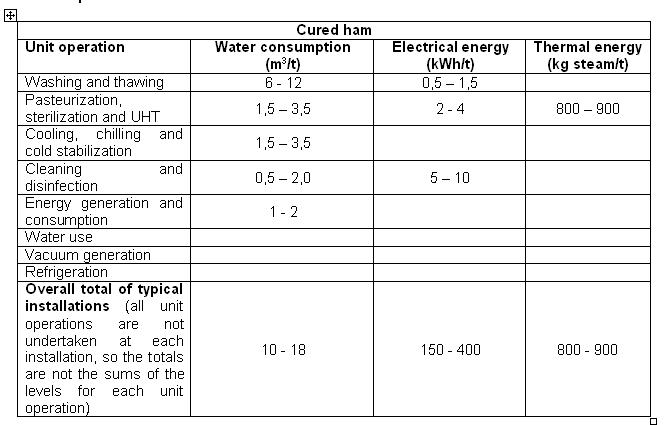

The following table summarizes consumption levels expressed per tonne of finished product reported for the Italian meat industry for canned meat manufacturing.

Table 3: Consumption levels for canned ham manufacturing in Italy

2. NEW TECHNOLOGIES:

- a) Changes in the process

No information is available.

- b) Changes in the energy distribution system

No information is available.

- c) Changes in the heat supply system

No information is available.