Casting of other metals

Back to EFFICIENCY FINDER FOR METAL INDUSTRY

Magnesium casting

Magnesium alloy castings are used for aerospace, automotive and electronic applications. The main advantage for using them is their light weight; typically magnesium alloys have a density of 1.8 g/ml compared with 2.7 g/ml for aluminium alloys. Aluminium is the principle alloying constituent of magnesium-based casting alloys, with zinc and manganese also present in small amounts. Pressure die-casting is the most commonly used casting process, due to the low casting temperature (650 – 700 ºC); both hot chamber and cold chamber die-casting machines are used. Sand moulding is applied to a lesser extent. Magnesium die-castings can be made with thinner walls than aluminium, but their use is limited by stiffness problems. The thinner walls allow the overall weight of the components to be substantially reduced, thus compensating for the higher alloy cost per kilogram. Gravity die-casting and sand casting are also used, particularly for more highly stressed castings. The use of magnesium alloy die-castings in automotive components is growing rapidly, with some vehicles already containing 10 – 20 kg of Mg components. The most popular parts made at present are instrument panel substrates, cross car beams, wheeldrives and seat frames.

Molten magnesium alloys attack firebrick and refractory furnace linings, resulting in harmful silicon contamination. Therefore steel crucibles are used. Iron is also slightly soluble in magnesium but it has a much less harmful effect than silicon. Scrap is usually cleaned and if possible shot blasted to remove any adhering sand as a further precaution against silicon pickup. To eliminate ladling, the molten alloy is, if possible, poured direct from the melting pot. Due to its very easy oxidation, magnesium alloys are melted under a cover using a cleansing flux or cover gas, to avoid oxidation losses and to prevent inclusions. Inhibitor powders are used to cover any exposed metal during holding and pouring, and are added to moulding-sand to prevent chemical reactions. The fluxless melting of Mg alloys requires another form of melt protection. For this purpose, sulphur hexafluoride (SF6) is used, as it promotes the formation of a protective film on liquid magnesium, which prevents oxidation. It is used at low concentration (<0.3 vol %) in a mix with air or air/CO2. SF6 is a greenhouse gas, considered harmful to the atmosphere and falls under the Kyoto protocol, which requires its use to be minimised. Austria and Denmark have issued regulations to ban the use of SF6 by 2003 and 2006, respectively. Magnesium alloys benefit from grain refinement, which is carried out by inoculation with carbonaceous materials. This used to be done with hexachloroethane, but since 1 July 2003 this product is banned in Europe generally to ensure environmental protection and for health and safety reasons. This applies both for magnesium and aluminium alloys. [175, Brown, 1999], [225, TWG, 2003]

Zinc casting

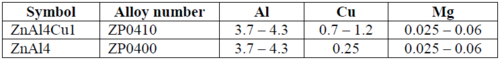

Zinc casting almost exclusively uses the pressure die-casting technique. In the EU, there are mainly two alloys in use, their compositions are given in Table 1. They are also referred to as Zamac, which in origin is a trade name. The basis of these alloys is pure zinc.

Table 1: Most common zinc alloys, contents in %

The zinc alloy is almost exclusively melted in a casting machine, of the hot chamber type. In

rare cases, and only when high production capacity is needed, centralised melting may be

applied.

Zinc alloys have comparable material properties to aluminium. The main differences are the lower melting point and the higher density of the zinc alloys (6.7 g/cm³ versus 2.6 – 2.7 g/cm³). They are mostly used for small pieces requiring high precision and a low wall thickness. They also allow a higher casting speed to be utilised and result in a 10 times longer die life (800000 to 1200000 shots), which makes them more suitable for large series (of small pieces). The zinc alloys are melted in an electrically or fuel heated cast iron crucible and cast using hot-chamber die-casting machines. The products are used in e.g. automotive and electronics components and in machine construction applications.

Lead casting

Lead is a low melting (melting point 327 ºC) heavy metal. Lead is relatively soft, corrosion-resistant and has good self-lubricating properties. The uses of lead castings include accumulator sheets, shielding material for X-rays and nuclear applications, and in ballast and counterweight materials. Mainly pressure and gravity die-casting techniques are applied.

Source: European Commission, Reference Document on Best Available Techniques in the Smitheries and Foundries Industry, May 2005