Cleaning of production halls and equipment with heat integration

Back to EFFICENCY FINDER OF FOOD INDUSTRY

GENERAL INFORMATION

The aim of cleaning and disinfection of production halls and equipment is to remove product remnants from the foregoing process run, other contaminants and microorganisms in order to guarantee product quality, food safety, line capacity, heat transfer and optimum operation of the equipment.

Depending on the process, it is common that wasted hot fluid carries solid particle. If the fluids passes through a heat exchanger, this solid particles can obstruct the channels. In order to ensure that the fluid can travel along the exchanger without problems, the most used heat exchangers are the tubular HX. The construction of the tubular HX allows a better “cleaning in process” (CIP). But If there is no need of avoiding big solid particles, other HX can be used as well.

TECHNOLOGY DESCRIPTION, TECHNIQUES AND METHODS

Tubular heat exchangers

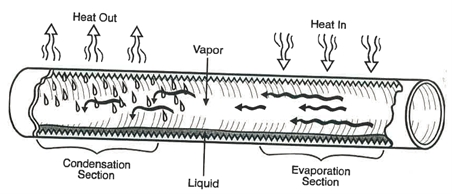

Tubular heat exchangers are systems that uses the natural convection as the physical phenomenon for the air movement. Tubular heat exchangers are built as a duct with a liquid layer inside. In one side of the duct, a heat flow passes through the exchangers, and heats up the walls of the duct and the liquid inside. The liquid evaporates and starts to move inside the duct. In the other side of the duct, a cold flow passes through the exchanger. In this side, the vapour that have moved on from the hot side get cold, transferring its heat to the exchanger duct walls, and it condensates. This way the tubular heat exchanger heats up the initially cold air.

Illustration 1: Tubular heat exchanger [1]

The air-air heat exchangers have the inconvenience of the air ducts, much bigger than the water or liquid ones have to be placed side by side, and this imposes physical limitations. These heat exchangers, with the desiccant wheel exception, do not recover latent heat.

The liquid-liquid heat exchangers do not need such a big place as the air-air heat exchangers. The liquid ducts are narrower and losses are lower. The auxiliary consumption is also lower.

CHANGES IN PROCESS

The installation of a heat exchanger does not implies a change in the process, because the main aim of the measure is to harness wasted fluid (and wasted energy) and pre-heat or pre-cool an incoming fluid to the process. Therefore, process can be kept identical, and the heat exchangers affects the fluid in an early stage and when it already has came out from the process.

Sometimes, when the CIP is used, machines are cleaned usually between batches. Depending on the frequency of these batches, it is common to install the cleaning device inside the machine (or connected to) and not as a previous heat exchange. In these situations, the process can be modified to include this cleaning periods between batches.

ENERGY SAVINGS POTENTIALS

CHANGES IN THE ENERGY DISTRIBUTION SYSTEM

REFERENCES

[1] Fundamentals of Heating Systems. ASHRAE