Coating oxide (chemical blacking) in surface industry

From Efficiency Finder

Jump to navigationJump to search

Back to EFFICIENCY FINDER FOR METAL INDUSTRY

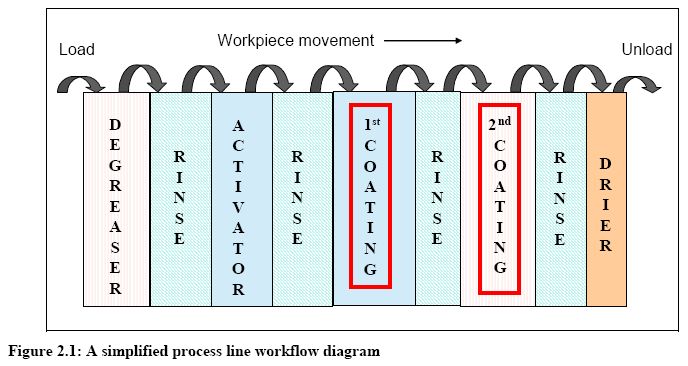

- Chemical blacking flowsheet

General flowsheet for the surface treatment of metals & plastics:

Literature: BAT for the surface treatment of metals & plastics, 2006

- Typical parameters of the process

| Process | Temperature [°C] | Heat transfer medium | Residence time | Chemicals | Concentration | Details | Literature |

| Chemical blacking of steel | 121-149 | Sodium hydroxide and sodium nitrate or a mixture of sodium nitrate and sodium nitrite | Sodium hydroxide: 75 wt% and sodium nitrate: 25 wt%; sodium nitrate: 12 wt% and sodium nitrite: 13 wt% | BAT for the surface treatment of metals and plastics, August 2006 | |||

| Chemical blacking of stainless steel | 370 | Molten sodium/porassium dichromate | |||||

| 60-90 | Chromic acid and sulphate | "Inox" process | |||||

| 125-130 | NaOH/NaNO2 | Black colouring of chromium nickel steel | |||||

| Chemical blacking of copper | 93-100 | Sodium hydroxide and sodium chlorite | Sodium hydroxide: 75 wt% and sodium chlorite: 25 wt% | ||||

| Chemical blacking of brass | 93-100 | 5-10 min | Sodium hydroxide and sodium chlorite | Sodium hydroxide: 85 wt% and sodium chlorite: 15 wt% |

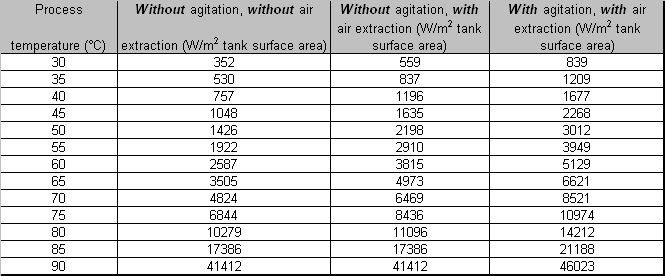

- Energy losses from the surface area of heated process solutions

LITERATURE: BAT for the Surface Treatment of Metals and Plastics, May 2005