Conversion coatings (phosphate layer) in surface industry

From Efficiency Finder

Jump to navigationJump to search

Back to EFFICIENCY FINDER FOR METAL INDUSTRY

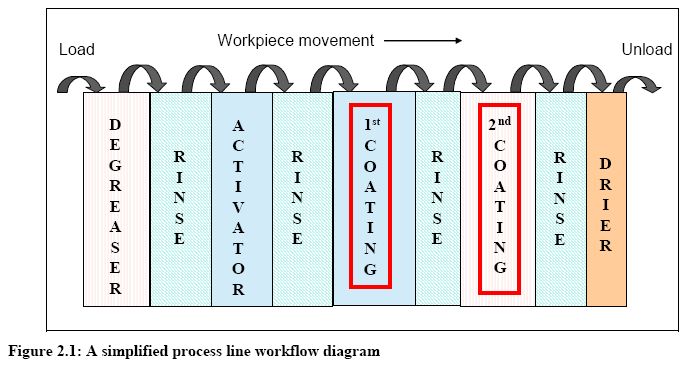

- Conversion coatings (phosphate) flowsheet

General flowsheet for the surface treatment of metals & plastics:

Literature: BAT for the surface treatment of metals & plastics, 2006

- Typical parameters of the process

| Process | Temperature [°C] | Heat transfer medium | Residence time | Chemicals | Concentration | Details | Literature |

| Alkali phosphating of aluminium | 40-70 (can be lowered to 25-35 with special bath compositions) | 5-10 sec | Aluminium, phospahte and fluoride solutions | 2-15 g/l | Spraying of strip material | BAT for the surface treatment of metals and plastics, August 2006 | |

| 1-3 min | Spraying or dipping of individuell parts | ||||||

| Zinc phospahting | up to 95 | zinc, phosphate ions and an oxidizing agent, often sodium nitrite | pH: 3,2 | ||||

| Phosphating iron and steel | 70-100 | 3-20 min | Zn, P2O5, NO3 | Zn: 14 g/l; P2O5: 9,5 g/l; NO3: 21 g/l; freies P2O5:P2=5 gesamt=0,5 | OE Patenschrift, Nr. 321055, Pateninhanber: Metallgesellschaft AG in Frankfurt am Main; Gegenstand: Verfahren zur Phosportierung von Eisen und Stahl, 28.Mai 1973 | ||

| Manganese phospahting | 95°C | continious | Institut für Normung, D. DIN EN 12476 (2001). |

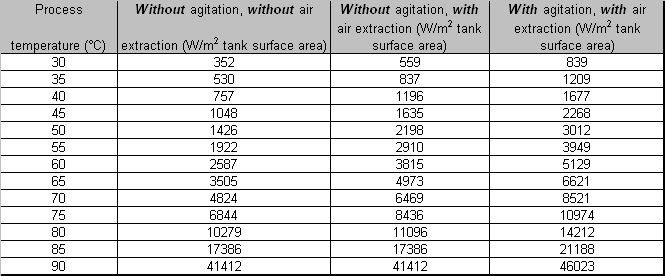

- Energy losses from the surface area of heated process solutions

LITERATURE: BAT for the Surface Treatment of Metals and Plastics, May 2005