Drying of clothes

Back to EFFICIENCY FINDER OF TEXTILE INDUSTRY

Energy consumption of drying processes

per kg of dry textile

- Tumble drying (Gas) : 2,7 MJ/kg

- Tumble drying (Steam) : 4,7 MJ/kg

- Ironing (Steam) : 4,5 MJ/kg

- Tunnel Finisher (Gas) : 2,5 MJ/kg

- Tunnel Finisher (Steam) : 3,0 MJ/kg

Steam consumption to evaporate 1 l of water

- Ironer (new): 1.6 kg of steam per litre of water

- Ironer (old, poor isolation): up to 2.5 kg of steam per litre of water

- Steam dryer: 2 kg of steam per litre of water

- Garment finisher: 1 kg of steam per litre of water

Drying process

- removal of excess water

- dry cotton contains 6-8 % of water in equilibrium with the atmosphere at standard conditions

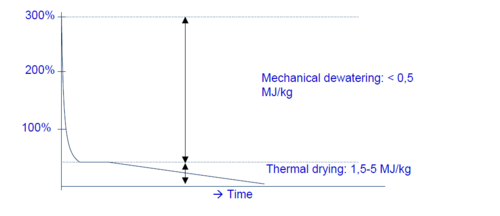

- drying is a two stage process = mechanical dewatering + thermal drying

- mechanical dewatering is fast and consumes less energy

- thermal drying is low and energy-intensive

Residual moisture in mass% as a function of time

Mechanical dewatering

- dewatering press

- centrifuge

Parameters for dewatering:

- Pressing time

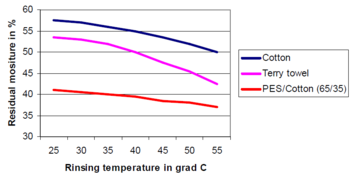

- Temperature of the rinsing water

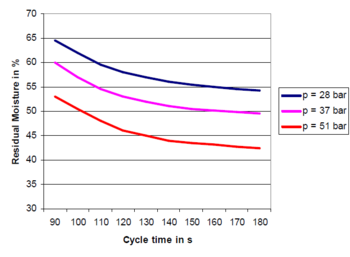

- Pressure/Centrifuge Speed

- Textile product

- Machine load

Residual moisture (in mass %) as a function of pressing cycle time and pressure p:

Residual moisture (in mass %) as a function of the temperature of the rinsing water and the textile material:

How to reduce residual moisture:

- Reducing the viscosity of the water (e. g. warm rinsing, heating of the last compartment, warm water circulation)

- Reduced ancillary times: increased extraction time with high pressure (press) or high speed (spin)

- Higher extraction pressure with optimised pressure build-up

- Highter g-factor in the spin

- Improved drainage fast lead away of the water

Tumble dryers

Heating of dryers

- electric heating (for small dryers with up to 30 kg batch size)

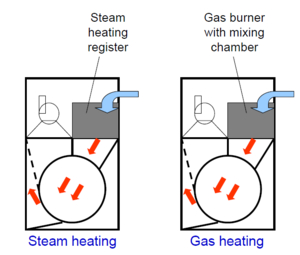

- steam

- gas

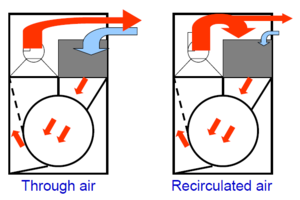

Schematics of steam and gas heated dryer (blue = incoming fresh air, red = hot drying air)

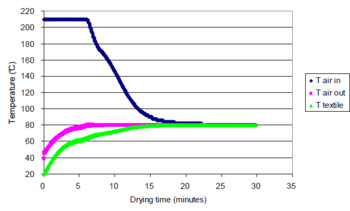

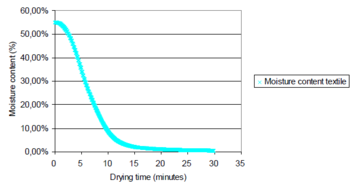

Temperature of air and textile during drying in a tumble dryer:

Moisture content of the textile during drying:

Determination of the end of drying

- Programming a fixed drying time

- Determing the switch-off point by the difference of the ingoing and outgoing air.

- Direct measuring: The drying time is precisely determined by the contactless infrared temperature detection of the articles.

Efficiency measures

Drying air circulation:

- 70 -80% of the hot drying air is circulated back into the chamber

- energy savings up to 30%

Other measures

- Optimization of mechanical dewatering

- Fast heating-up of the process by a high temperature of the in-going air at the beginning of the process will shorten drying times and minimize energy consumption. Textile temperature is still low in this part of the drying process (see temperature graph), so no textile damage will occur

- Optimal textile movement in the drum by adapting drum movement to load to ensure optimal heat transfer

- Optimal loading of the drum, avoid overloading but fill the machine to the optimum load

- Optimal end-point determination to avoid both still wet laundry as a result of too short drying and over-drying by extended drying

- Frequent cleaning of filter to enable optimal air recirculation

Source

Leonardo da Vinci project Laundry Sustainability