Eberhard (Austria)

Back to EFFICIENCY FINDER FOR METAL INDUSTRY

Back to Information about iron

- 1. Solar integration

No solar plant has been built yet. The first step was to find possibilities for heat-recovery and energy efficiency.

- 2. Industry Sector

(Surface) treatment of metals

- 3. Industrial application

Solar application: water heating for the black-finishing baths and maybe for heating the production halls

- 4. Process description

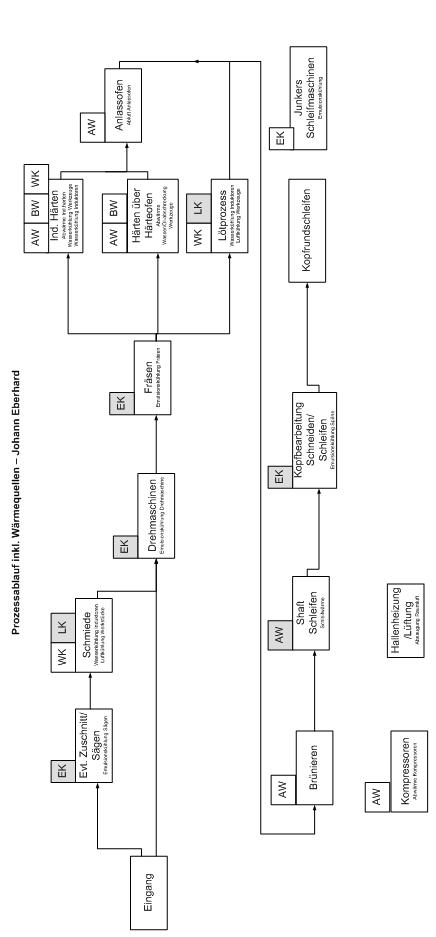

- Process flowsheet:

- Processes:

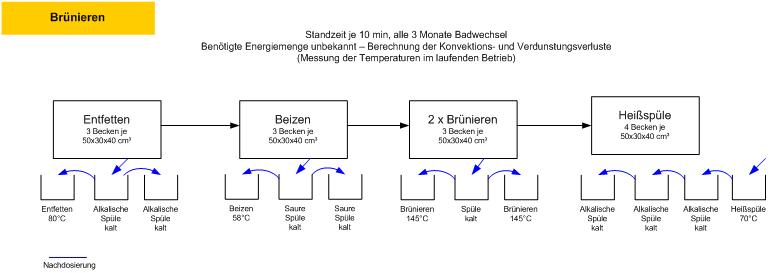

Black finishing:

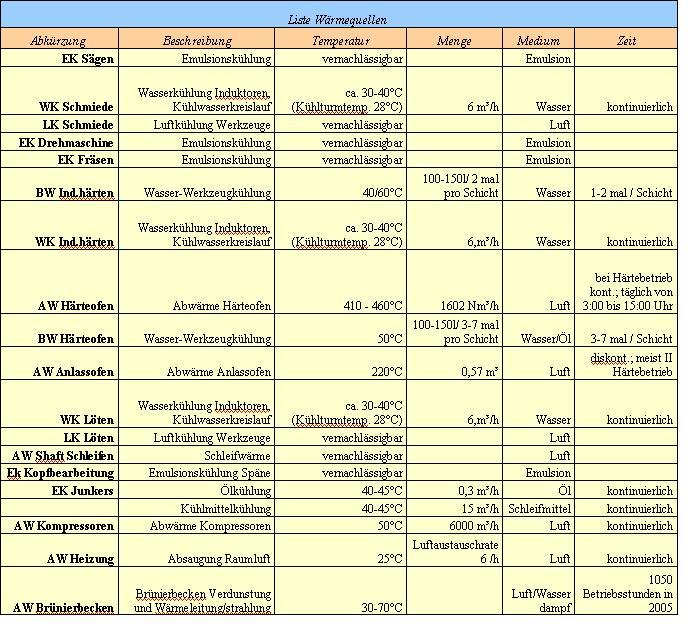

- 5. Energy flows and temperature ranges

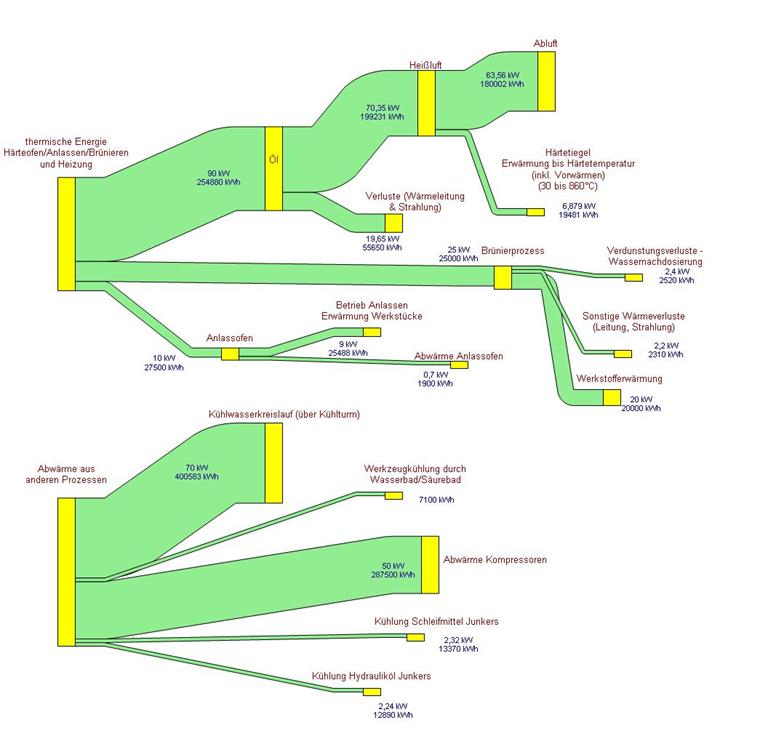

- Main heat supply system and fuel:

- Main fuels: oil & electrical energy

- Total electrical energy consumption: 80.000 – 100.000 kWh/a Electrical power: 250 – 270 kW

- Total oil consumption: 103 litres/day 2006: 38.205 litres, heating value: 10 kWh/l fuel heat capacity: 382.050 kWh

- Thermal energy demand for black-finishing bath: 10.500 – 21.000 kWh (not exactly known)

- Connection power for oil-heating: 140.000 kWh Heating demand that could be covered by heat-recovery: 420.000 kWh

- Energy consumption (Sankey):

- Temperature ranges and other parameters:

- 6. Solar Thermal Plant

- Used scheme: No information available.

Description:

The solar energy is used for direct after-heating of the black-finishing baths, because water-baths at low- and middle-temperature levels are ideal for integrating solar process heat. To integrate such a system, the plant engineering would have to be changed.

- Performance of the planned solar plant:

A solar plant for providing the required 21.000 kWh with 30% solar ratio has to have an area of 20 m² and will produce 7000 kWh/a. These numbers are not calculated, but are only experience-data.

- Pictures of the built solar system:

No information available.

- 7. Energy savings

- Pinch analysis results:

No information is available.

- Energy savings:

No information is available.

- 8. Economic evaluation

- Economic parameters of the built solar system:

Investing costs: ~ 10.000 € Promotion: 30%

Back to EFFICIENCY FINDER FOR METAL INDUSTRY

Back to Information about iron