Back to EFFICENCY FINDER OF FOOD INDUSTRY

|

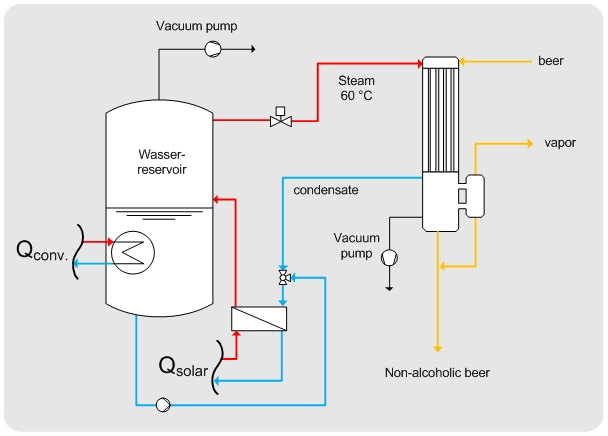

Example how to integrate solar heat for dealcoholization of beer.

Dealcoholization processes are necessary to meet the growingmarketfor non-alcoholic(<0.05% by volume) andlow-alcoholic beer (<0.5% by volume). In addition to arrested fermentation andreverse osmosis, there are also thermal processesto producenon-alcoholic beers. However, notall breweries producenon-alcoholic beer. Dealcoholization processes are often foundinlarge breweries. The installations areusually designed with relatively low production capacities to maintain long and constant operation times.

Typical installations used for thermaldealcoholizationare rectification columns,thin film- andfalling film evaporators.Rectification columnsandfalling film evaporatorsare usually designed in multi-stage. Based on the sensitive product characteristics, the evaporator is operated with slight vaccum (both, product andheating side). Thereby thedealcoholizationoccursat low temperatures. Usually saturated steam atabout 60 °C is used as heating medium.

A heating systemconsistingof aconventionalheatedstorage, asolar heat exchangeranda vacuum pump are required to assist the dealcoholization process with solar energy.As shown in Figure 9, solar heat is used to preheat the condensate return. In case of insufficient solar irradiation, the condensate temperature can be increased with the conventional heated storage. Due to the illustrated bypass it is possible to use solar heatalready for the start up the plant.

|

| Source: Schmitt, B., 2014. Integration of solar heating plants for supply of process heat in industrial companies (in German language), Dissertation University of Kassel, Shaker Verlag, Aachen, Germany.

|

Back to EFFICENCY FINDER OF FOOD INDUSTRY