Finishing of wool

From Efficiency Finder

⧼monobook-jumptonavigation⧽⧼monobook-jumptosearch⧽

Back to EFFICIENCY FINDER FOR TEXTILE INDUSTRY

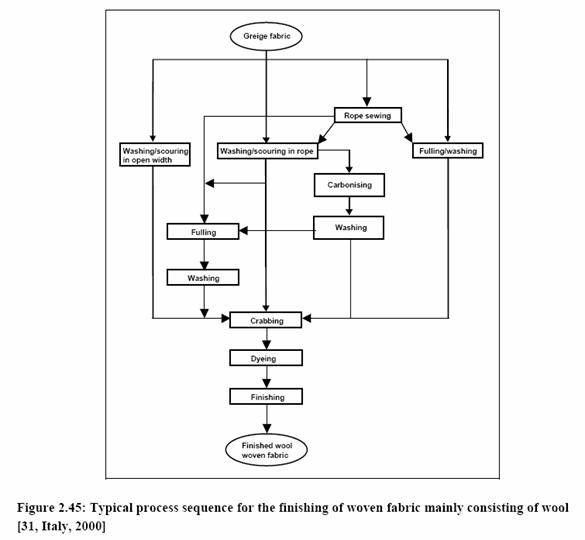

- Wool finishing Flowsheet

source: BAT 2003

- Typical parameters of the process

| Techniques | Temperature [°C] | Pressure (bar) | Heat transfer medium | Residence Time | pH | Additional information | Literature |

| Fabric setting | Very hot, near boiling point; afterwards shock cooling with cold water | water | to relax and stabilize latenst strains | 2005 Australian Wool Innovation Pty Ltd: Finishing of woven wool (pdf) | |||

| Scouring: rope processing | 40 | water with dergent (synthetic, non-ionic, anionic | 8-8,5 | for open width processing | 2005 Australian Wool Innovation Pty Ltd: Finishing of woven wool (pdf) | ||

| Drying | 120-140 | hot air | on stenter | 2005 Australian Wool Innovation Pty Ltd: Finishing of woven wool (pdf) | |||

| Steaming | 120 | 1 | temperatures vary with quality | 2005 Australian Wool Innovation Pty Ltd: Finishing of woven wool (pdf) |

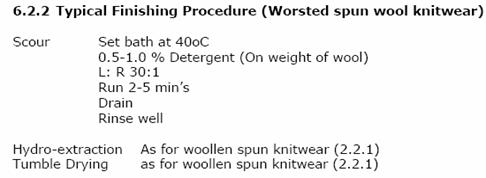

source: 2005 Australian Wool Innovation Pty Ltd: Finishing of knitted wool (pdf)

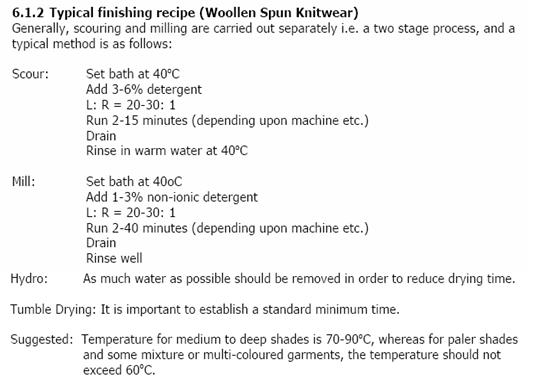

source: 2005 Australian Wool Innovation Pty Ltd: Finishing of knitted wool (pdf)

- Energy consumption

| Fibres/Fabrics etc. | Process/technique | Water consumtion [l/kg] | Thermal energy [MJ/kg] | Electrical Energy [MJ/kg] | Energy consumption | Literature |

| tops/floc, mainly WO | finishing mill | ca. 40 (for more hank:80) | 11-28 (for more hank:26) | ca. 0,8 (for more henk: 1,1) | BAT in textile industry 2003 | |

| knitted fabric, mainly WO | finishing mill | 70-120 | 9,5 | 67 | BAT in textile industry 2003 |