Information about meat production

Back to EFFICENCY FINDER OF FOOD INDUSTRY

General information

The energy consumption is one of the key production factors in the meat processing industry. It has a great impact on the meat processing plant efficiency and the natural environment. Consumption of energy carriers in meat processing plants depends on many factors such as, for example, size and structure of output, production technology used, thermo-physical properties of raw materials, mechanisation of production processes and utilization of processing capacity. An average about 775kWh of energy required to produce a tonne of beef and 685kWh per tonne of sheep meat (based on the energy used for slaughtering, cutting and retail packing). In meat processing, moderate levels of both electrical and thermal energy are consumed in wide range of processes and applications. Electricity is used for refrigeration, compressed air, ventilation, lighting, powering the operating equipment in the slaughter, boning and by-product processing areas such as saws, hoists, conveyors, packing machines and electrical stimulation. Gas and oil are primarily used to provide heat and hot water for the factories (eg. for scalding, knife sterilisation, cleaning process areas and machinery, by product processing and heating).

Products

- poultry (chicken, turkey)

- canned meat (beef muscle in gelatine)

- bacon

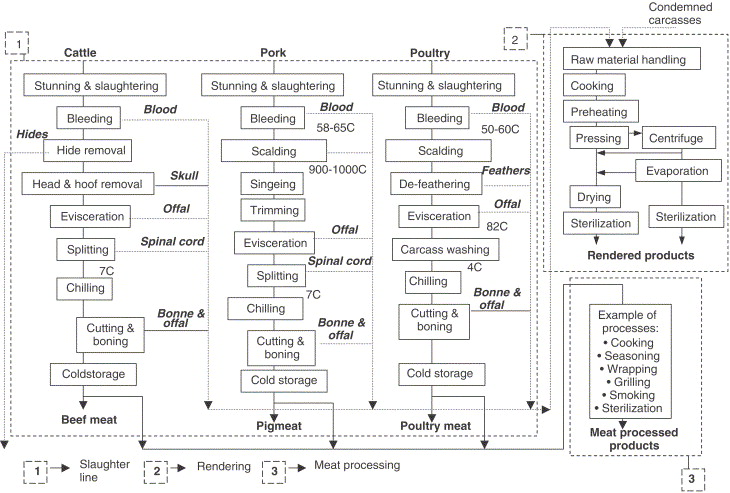

Processes in meat production

Benchmarks

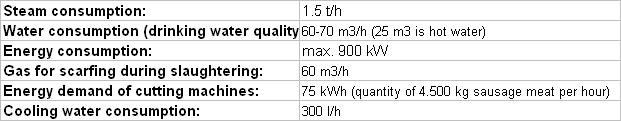

Table of energy consumption for an abattoir with an output of 200 up to 250 pigs or 40 up to 60 cattle per hour: (Heiss, R. [Hrsg.]: Lebensmitteltechnologie)

For more benchmark data, check above the sector Products

Literature

[1] Ramirez C A et.al.(2006) Energy 31, 2047- 2063 [2] ] Heiss, R.(1990) Lebensmitteltechnologie