Process Info: Pasteurization in dairies

Back to Pasteurization in dairies

1. DESCRIPTION OF TECHNIQUES, METHODS AND EQUIPMENT

- Time-temperature curve:

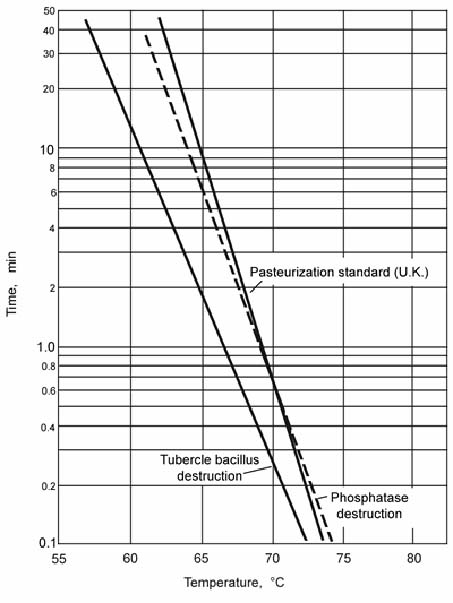

The most common application is pasteurization of liquid milk. In the case of milk, the pathogenic organism that is of classical importance is Mycobacterium tuberculosis, and the time-temperature curve for the inactivation of this bacillus is shown in the figure below:

Figure 1: Time/temperature curve for the inactivation of Mycobacterium tuberculosis

LITERATURE: Unit Operations in Food Processing - the Web Edition, R. L. EARLE, 1983, Published by NZIFST (Inc.), http://www.nzifst.org.nz/unitoperations

This curve can be applied to determine the necessary holding time and temperature in the same way as with the sterilization thermal death curves.

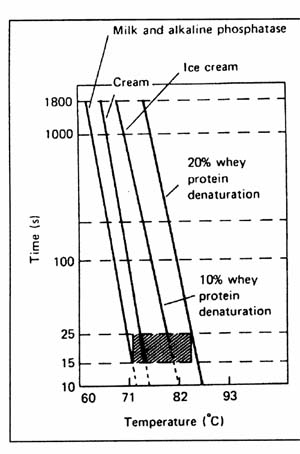

Figure 2: Time/temperature curve

- Ontario pasteurization regulations:

- Milk

- 63°C for not less than 30min, 72°C for not less than 16sec, or equivalent destruction of pathogens and the enzyme phosphatase as permitted by Ontario Provincial Government authorities. Milk is deemed pasteurized if it tests negative for alkaline phosphatase.

- Frozen dairy dessert mix (ice cream or ice milk, egg nog)

- at least 69°C for not less than 30min, at least 80°C for not less than 25sec, other time temperature combinations must be approved (e.g. 83°C/16sec).

- Milk based products with 10% mf or higher, or added sugar (cream, chocolate milk, etc)

- 66°C/30min, 75°C/16sec

- Time-temperature in continuous heat exchangers

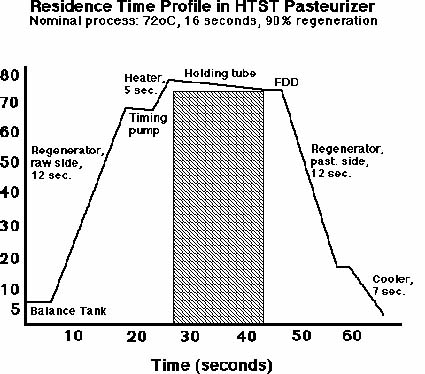

- However, the times involved are very much shorter, and controlled rapid heating in continuous heat exchangers simplifies the calculations so that only the holding period is really important. For example, 30min at 62.8°C in the older pasteurizing plants and 15sec at 71.7°C in the so-called high temperature/short time (HTST) process are sufficient. The hatched area in the graph below represents the area under the time temperature curve that is taken into consideration for thermal lethality calculations:

Figure 3: Residence time profile in HTST pasteurizer LITERATURE: http://www.foodsci.uoguelph.ca/dairyedu/home.html

- An even faster process using a temperature of 126.7°C for 4sec is claimed to be sufficient. The most generally used equipment is the plate heat exchanger.

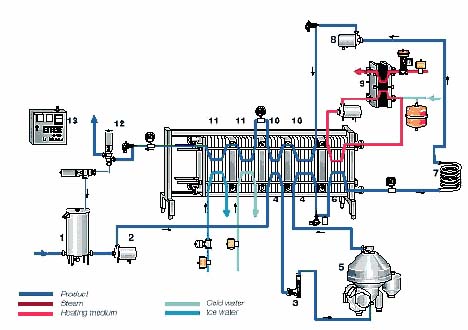

- Process of milk pasteurization:

- The figure below shows the process of milk pasteurization:

Figure 4: Milk pasteurization

- HTST milk pasteurization

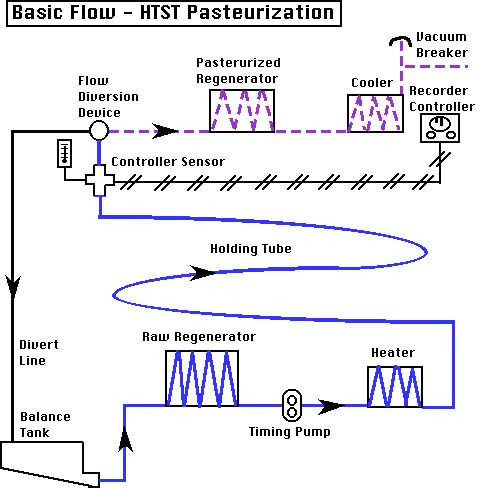

- HTST pasteurization milk flow overview:

- Cold raw milk at 4°C in a constant level tank is drawn into the regenerator section of pasteurizer. Here it is warmed to approximately 57-68°C by heat given up by hot pasteurized milk flowing in a counter current direction on the opposite side of thin, stainless steel plates. The raw milk is forced through the heater section where hot water on opposite sides of the plates heat milk to a temperature of at least 72°C. The milk, at pasteurization temperature and under pressure, flows through the holding tube where it is held for at least 16sec. After passing temperature sensors of an indicating thermometer and a recorder-controller at the end of the holding tube, milk passes into the flow diversion device (FDD). The FDD assumes a forward-flow position if the milk passes the recorder-controller at the preset cut-in temperature (>72°C). The FDD remains in normal position which is in diverted-flow if milk has not achieved preset cut-in temperature. The improperly heated milk flows through the diverted flow line of the FDD back to the raw milk constant level tank. Properly heated milk flows through the forward flow part of the FDD to the pasteurized milk regenerator section where it gives up heat to the raw product and in turn is cooled to approximately 32°C - 9°C.

- The warm milk passes through the cooling section where it is cooled to 4°C or below by coolant on the opposite sides of the thin, stainless steel plates. The cold, pasteurized milk passes through a vacuum breaker at least 12 inches above the highest raw milk in the HTST system then on to a storage tank filler for packaging:

Figure 5: Basic flow of HTST Milk Pasteurization LITERATURE: http://www.foodsci.uoguelph.ca/dairyedu/home.html

- Basic component equipment of HTST pasteurizer:

- The basic component equipment of a HTST pasteurizer are:

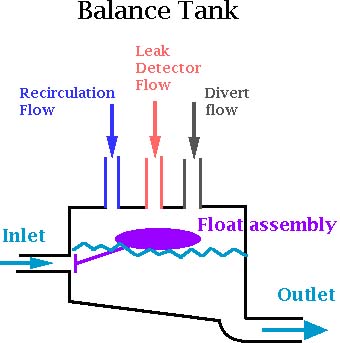

- (a) Balance tank:

- The balance, or constant level tank provides a constant supply of milk. It is equipped with a float valve assembly which controls the liquid level nearly constant ensuring uniform head pressure on the product leaving the tank. The overflow level must always be below the level of lowest milk passage in regenerator. It, therefore, helps to maintain a higher pressure on the pasteurized side of the heat exchanger. The balance tank also prevents air from entering the pasteurizer by placing the top of the outlet pipe lower than the lowest point in the tank and creating downward slopes of at least 2%. The balance tank provides a means for recirculation of diverted or pasteurized milk.

Figure 6: Balance tank LITERATURE: http://www.energymanagertraining.com

- (b) Regenerator:

- Heating and cooling energy can be saved by using a regenerator which utilizes the heat content of the pasteurized milk to warm the incoming cold milk.

- (c) Timing pump:

- The timing pump draws product through the raw regenerator and pushes milk under pressure through pasteurized regenerator. It governs the rate of flow through the holding tube. It must be a positive displacement pump equipped with variable speed drive that can be legally sealed at the maximum rate to give minimum holding time in holding tubes. It also must be interwired so it only operates when FDD is fully forward or fully diverted, and must be "fail-safe". A centrifigal pump with magnetic flow meter and controller may also be used.

- (d) Holding tube:

- Must slope upwards 1/4"/ft. in direction of flow to eliminate air entrapment so nothing flows faster at air pocket restrictions.

- (e) Indicating thermometer:

- The indicating thermometer is considered the most accurate temperature measurement. It is the official temperature to which the safety thermal limit recorder (STLR ) is adjusted. The probe should sit as close as possible to STLR probe and be located not greater than 18 inches upstream of the flow diversion device.

- (f) Recorder-controller:

- The STLR records the temperature of the milk and the time of day. It monitors, controls and records the position of the flow diversion device (FDD) and supplies power to the FDD during forward flow. There are both pneumatic and electronic types of controllers. The operator is responsible for recording the date, shift, equipment, ID, product and amount, indicating thermometer temperature, cleansing cycles, cut in and cut out temperatures, any connects for unusual circumstances, and his/her signature.

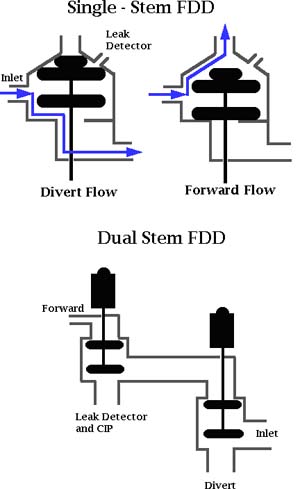

- (g) Flow diversion device:

- Also called the flow diversion valve (FDV), it is located at the downstream end of the upward sloping holding tube. It is essentially a 3-way valve, which, at temperatures greater than 72°C, opens to forward flow. This step requires power. At temperatures less than 72°C, the valve recloses to the normal position and diverts the milk back to the balance tank. It is important to note that the FDD operates on the measured temperature, not time, at the end of the holding period. There are two types of FDD:

- single stem: an older valve system that has the disadvantage that it can't be cleaned in place.

- dual stem: consists of 2 valves in series for additional fail safe systems. This FDD can be cleaned in place and is more suited for automation.

Figure 7: Single and dual stem flow diversion devices. LITERATURE: http://www.energymanagertraining.com

- (e) Vacuum breaker:

- At the pasteurized product discharge is a vacuum breaker which breaks to atmospheric pressure. It must be located greater than 12 inches above the highest point of raw product in system. It ensures that nothing downstream is creating suction on the pasteurized side.

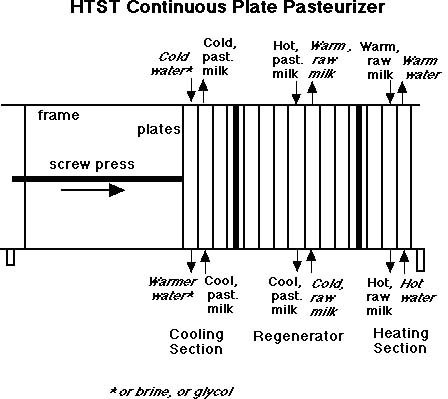

- HTST continuous milk pasteurization:

The HTST Continuous Plate Milk Pasteurizer is shown in Figure 5:

Figure 8: HTST Continuous Plate Pasteurizer LITERATURE: http://www.foodsci.uoguelph.ca/dairyedu/home.html

2. NEW TECHNOLOGIES:

- a) Changes in the process

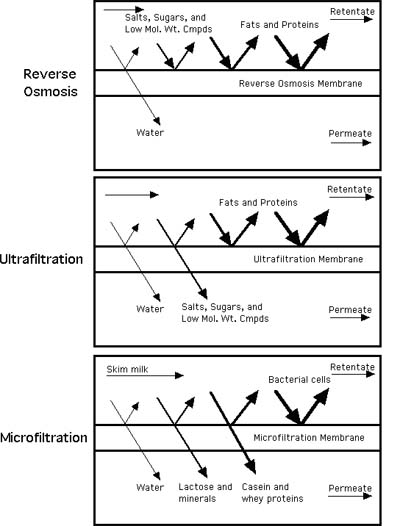

- Membrane processes of milk: (Operations in Food Processing - the Web Edition, R. L. EARLE, 1983) (see also Membrane processes in the food industry).

- a) Description of the technology:

- Membrane processes are typically used in the milk industry to condense liquid mixtures (BAT in the Food, Drink and Milk Industries, June 2005). Membrane processes are also used as an alternative technology to pasteurization and sterilization.

- The schemes below show three different types of membrane processes in milk production. The size of the membrane pores result in different final products. Microfiltration is able to remove bacterial cells from liquid milk products:

Figure 4: Reverse osmosis, ultrafiltration, microfiltration in milk production LITERATURE: http://www.energymanagertraining.com

- b) Description of suitable energy supply systems:

- Membrane processes may result in reduced heat consumption, but electrical power is required to pump liquid through a semi-permeable membrane.

- c) Possible energy savings reachable by those measures:

- No information available.

- d) Economic evaluations:

- No information available.

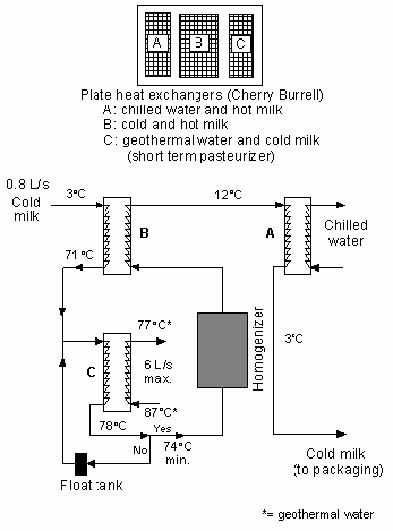

- Geothermal pasteurization of milk:

- a) Description of the technology:

Figure 9: Geothermal pasteurization of milk

- b) Description of suitable energy supply systems:

- The process is similar to the conventional pasteurization process, but geothermal water is used instead of hot water or steam.

- c) Possible energy savings reachable by those measures:

- No information available.

- d) Economic evaluations:

- No information available.

- b) Changes in the energy distribution system

No information is available.

- c) Changes in the heat supply system

No information is available.

Back to Pasteurization in dairies