Scouring in textile industry

Back to EFFICIENCY FINDER FOR TEXTILE INDUSTRY

1. OBJECTIVE

Scouring (also known as boiling-off or kier boiling) is aimed at the extraction of impurities present on the raw fibre or picked up at a later stage such as (BAT for the Textiles Industry, July 2003):

- pectins

- fat and waxes

- proteins

- inorganic substances, such as alkali metal salts, calcium and magnesium phosphates,

- aluminium and iron oxides

- sizes (when scouring is carried out on woven fabric before desizing)

- residual sizes and sizing degradation products (when scouring is carried out on woven fabric after desizing).

2. FIELD OF APPLICATION

Scouring can be carried out as a separate step of the process or in combination with other treatments (usually bleaching or desizing) on all kind of substrates (BAT for the Textiles Industry, July 2003): • woven fabric (sized or desized) • knitted fabric • yarn.

3. DESCRIPTION OF TECHNIQUES, METHODS AND EQUIPMENT

For yarn and knitted fabric, scouring is usually a batch process which is carried out in the same equipment that will subsequently be used for dyeing (mainly autoclaves or hank dyeing machines for yarn and overflows, jets, etc. for knitted fabric). Woven fabric is scoured in continuous mode using the pad-steam process (BAT for the Textiles Industry, July 2003).

4. COMPETITIVE TECHNOLOGIES AND ENERGY SAVING POTENTIALS

- a) Changes in the process

- Enzymatic scouring: (BAT for the Textiles Industry, July 2003)

Enzymatic desizing using amylases is an established process that has been in use for many years. More recently, pectinases have shown promise in replacing the traditional alkaline scouring treatment. Some auxiliary suppliers have introduced an enzymatic process to remove hydrophobic and other non-cellulosic components from cotton. The new process operates at mild pH conditions over a broad temperature range and can be applied using equipment such as jet machines.

It is claimed that, due to a better bleachability of enzyme-scoured textiles, bleaching can be carried out with reduced amounts of bleaching chemicals and auxiliaries. Enzymes actually make the substrate more hydrophilic (which should explain better bleachability), but they are not able to destroy wax and seeds, which are therefore removed in the subsequent bleaching process.

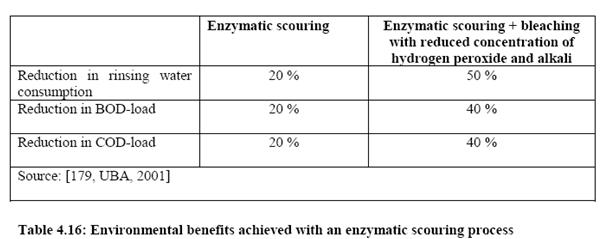

Main achieved environmental benefits Sodium hydroxide used in conventional scouring treatment is no longer necessary. Furthermore, the following advantages are reported over the traditional procedure:

Operational data A typical process for a pad-batch process combining scouring and desizing in one single step is as follows:

- impregnation at 60°C (pH 8 – 9.5) with:

- 2-3 ml/l wetting agent

- 2-5 ml/l emulsifier

- 5-10 ml/l enzymatic compound

- 4-6 ml/l amylase

- 2-3 g/l salt

- storing for 3-12 h, depending on the amount and type of starch

- extraction and rinsing

- Use of fully closed-loop installations for fabric washing (scouring) with organic solvent: (BAT for the Textiles Industry, July 2003)

Continuously operating solvent scouring installations for open-width fabrics have been known since the late 1960s. They have been used by the textile finishing industry in different production sectors for over thirty years mainly because of the advantages of organic solvents over water in solving technical and qualitative problems related to fabric cleaning.

The specific heat of PER (the solvent most commonly used) is about 1/5 of that of water and the latent heat of evaporation is over 10 times lower, resulting in about 90% reduction of the total heat requirement for evaporation in favour of PER. This means much faster and cheaper evaporation with significant savings in time and energy during drying.

The lower surface tension of PER results in a quicker and deeper fibre impregnation, thereby making any cleaning or finishing treatment more complete and uniform.

Nevertheless, the application of PER requires extreme care and sophisticated techniques for reducing and minimising its harmfulness potential for the environment and humans.

The following gives an insight into the features of the new generation of technologically advanced solvent treatment installations compared to the traditional ones.

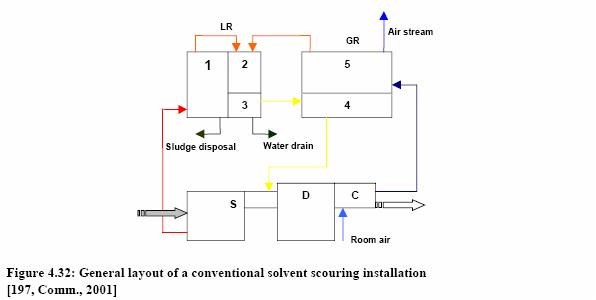

In general terms, the components of a typical installation of the 1970s, schematically represented in the diagram below, are: S. scouring unit D. drying unit C. cooling section

Solvent recovery equipment: LR liquid recovery / sludge disposal (1 distillation, 2 condensation, 3 water separation, 4 solvent tank) GR gaseous recovery (5 open-loop active charcoal filters)

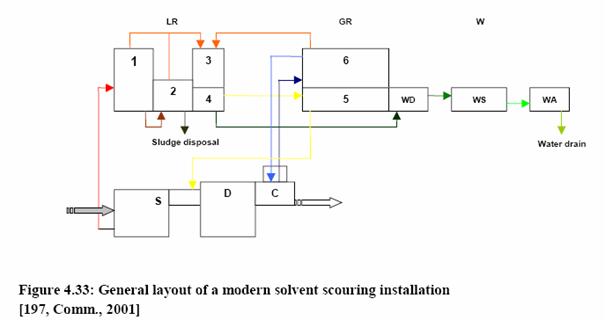

The components of a typical modern installation, schematically represented in the figure below, are: S. scouring D. drying unit E. cooling section

Solvent recovery equipment: LR liquid recovery / sludge disposal (1 main distillation, 2 sludge distillation, 3 condensation, 4 water separation, 5 solvent tank) GR gaseous recovery (6 closed-loop active charcoal filters) W. water treatment WD decantation WS air stripping WA charcoal absorption

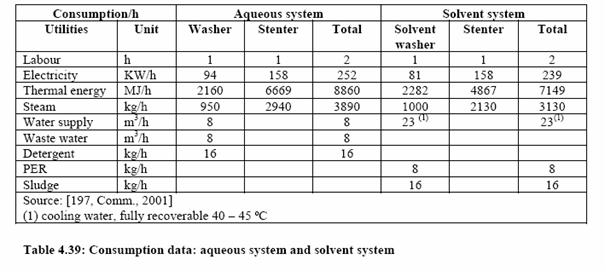

Main benefits The benefits of scouring with organic solvent lie essentially in following points:

- reduction of both water and energy consumption, due to the dry-to-dry processing and to the heat requirement for solvent evaporation compared to water

- environmental benefits concenring organic load, auxiliary usage etc. (see BAT in textile industry, 2003 – Section 4)

- b) Changes in the energy distribution system

No information is available.

- c) Changes in the heat supply system

No information is available.