Scouring of cotton and bast fibres

From Efficiency Finder

Jump to navigationJump to search

Back to EFFICIENCY FINDER FOR TEXTILE INDUSTRY

- Process Flowsheet

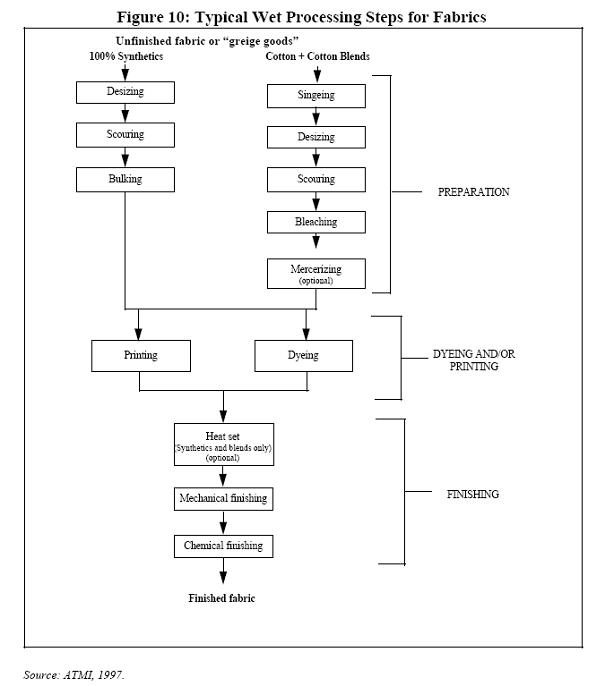

- a) Typical wet processing for fabrics

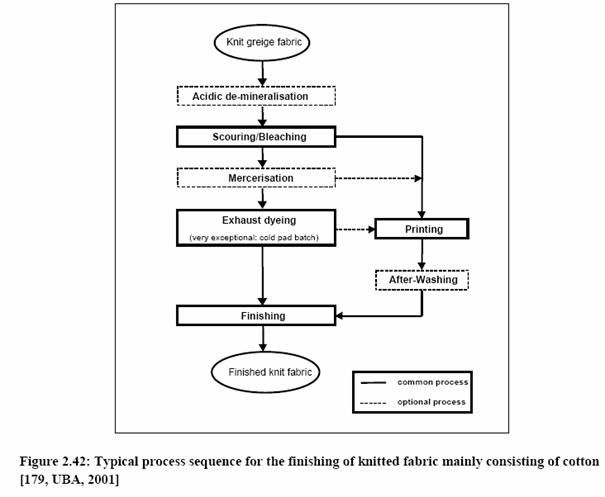

- b) Typical process sequence for the finishing of cotton knitted fabric

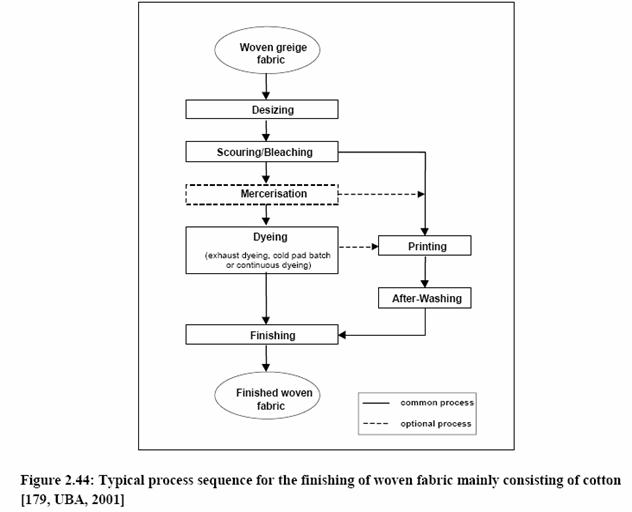

- c) Typical process sequence for the finishing of cotton woven fabric

- Typical parameters of the process

| Techniques | Temperature [°C] | Water consumption | Pressure (bar) | Heat transfer medium | Residence Time | Additional information | Literature: |

| Bath | containing: NaOH: 3%, surfactant: 0.2-0.4%, sequestrant: 0.1-0.2% | Chemistry and Technology of Fabric preparation and finishing | |||||

| processing fabric | 100 | 1 h | in beck or jet | Chemistry and Technology of Fabric preparation and finishing | |||

| Rinsing | Chemistry and Technology of Fabric preparation and finishing | ||||||

| Saturation of fabric | containing: NaOH: 6-8%, surfactant: 0.2-0.4%, sequestrant: 0.1-0.2% | Chemistry and Technology of Fabric preparation and finishing | |||||

| steaming | 100 | in j-box or steamer | Chemistry and Technology of Fabric preparation and finishing | ||||

| Rinsing | ~ 70 | Chemistry and Technology of Fabric preparation and finishing |