Sealing following anodizing of aluminium

From Efficiency Finder

Jump to navigationJump to search

Back to EFFICIENCY FINDER FOR METAL INDUSTRY

- Sealing following anodizing of aluminium

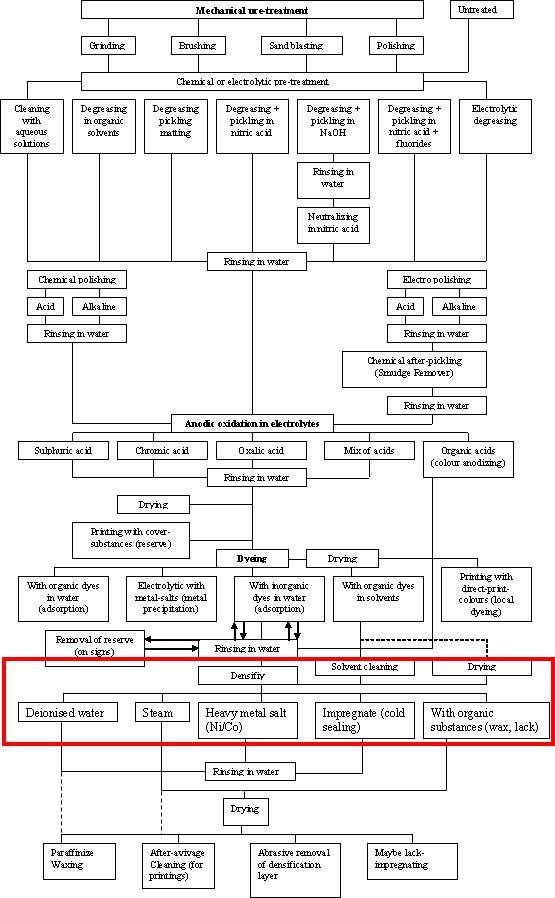

Example flowsheet:

Scheme of different possibilities of surface treatment of aluminium:

Literature: Oberflächenbehandlung von Aluminium; T.W. Jelinek; Eugen G. Leuze Verlag, D-88348; 1997

- Typical parameters of the process

| Process | Temperature [°C] | Chemicals | Concentration [g/l] | Residence time | Details | Literature |

| Sealing in nickel/cobalt- acetate solutions | 70-90 | 1. Nickelacetate, 2. Cobaltacetate, 3. Boric acid, 4. Distilled Water | 1. 5-5,8, 2. 1, 3. 8 | 15-20 min | pH:5-6(optimum) | Oberflächenbehandlung von Aluminium; T.W. Jelinek, Eugen G. Leue Verlag, D- 88348; 1997 |

| Sealing in dichromate solutions | 90-95 | 1. Kaliumdichromate and 2. Sodiumcarbonate OR 3. Sodiumhydroxide | 1. 100, 2. 18, 3. 13 | pH: 6-7 | ||

| Sealing in dichromate solution | 95-100 | Sodium- or kaliumdichromate | 50 | 30-60 min | pH: 8-9; solution has to be free of chlorides and sulfates; maybe rinsing with water | |

| Sealing in concentrated sodium-, kalium- or calciumsulfate/chloride solutions | 90-100 | Concentrated sodium-, kalium or calciumsulfate/chloride solutions | 120-200 | 15-60 min | pH:6,5-8 | |

| Cold sealing | 25-35 | Nickelfluoride, polar alcohol | Ni: 1,2, Ni:F: 1,5:2 | 0,6-1 min | pH: 5,5-6 |