Difference between revisions of "Solar application for heating of production halls"

From Efficiency Finder

| (One intermediate revision by one other user not shown) | |||

| Line 2: | Line 2: | ||

| − | ''' | + | {| class="wikitable" |

| + | !colspan="6"|Usually the boiler house is delivering heat to the production processes as well as space heating for | ||

| + | office buildings, production halls and stockrooms. Therefore, solar heat integration concepts are mainly linked to the supply level. | ||

| + | |- | ||

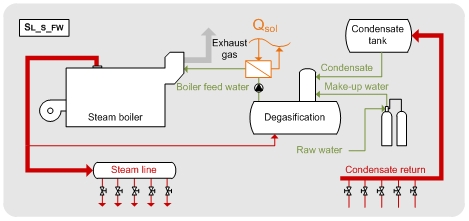

| + | |[[File:SL_S_FW.jpg]] | ||

| + | |'''SL_S_FW –solar heating of boiler feed water''' | ||

| + | The serial integration of solar heat for heating of boiler feed water takes place after degasification. Usually the degasification is operated around 105 °C. The set temperature of boiler feed water depends on the supply pressure of the steam boiler and is usually in the range of 160..220 °C (equals 6 to 23 bar). Typically boiler feed water is (or should be) preheated by an economizer before entering the steam boiler (by approx. 30 K). The remaining temperature difference can be supplied by solar heat. Based on the dimensioning of economizers, a solar preheating of boiler feed water prior to the economizer is not always possible. | ||

| + | |- | ||

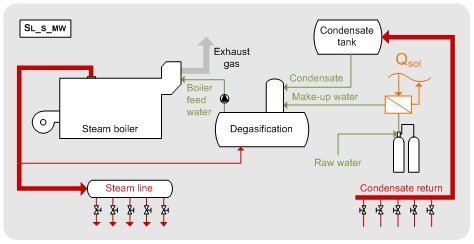

| + | |[[File:SL_S_MW.jpg]] | ||

| + | |'''SL_S_MW – solar heating of make-up water''' | ||

| − | + | The last integration concept for steam systems is preheating of make-up water which is required to compensate losses of condensate caused by flash evaporation, blow down and direct steam consumption. Make-up water is fed into the degasification after desalting. In principle, the amount of make-up water can be heated by solar energy prior to degasification. However, several waste heat sources within the boiler house can significantly decrease the potential for implementation of solar heat. | |

| + | |- | ||

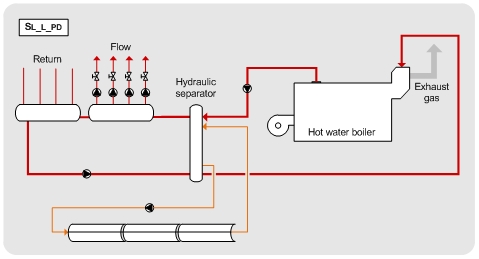

| + | |[[File:SL_L_P.jpg]] | ||

| + | |'''SL_L_P – parallel integration''' | ||

| − | + | For the parallel integration of solar heat into hot water circuits, the return is divided prior to the conventional boiler and partially directed through the solar heating system and fed back into the flow. Therefore, the control of the solar heating system has to ensure that the return is heated to the required flow temperature. The integration can be realized directly (SL_L_PD) or indirectly (SL_L_PI). For the direct integration the water of the heating circuit flows directly through the collectors, while a heat exchanger is used for the indirect integration. | |

| + | |- | ||

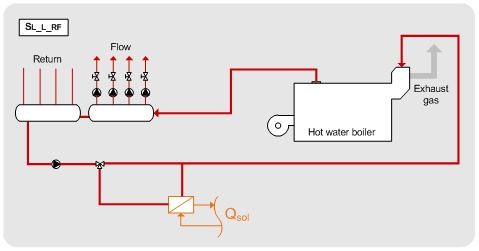

| + | |[[File:SL_L_RF.jpg]] | ||

| + | |'''SL_L_RF –solar return flow boost''' | ||

| − | + | The serial integration of solar heat is similar to integration concept SL_L_PI, with the difference that the return is preheated. Therefore, no fixed set temperature has to be supplied by the solar heating system. Return line heating might not be desired by the industrial plant operator if the efficiency of the conventional heating system is affected in a negative way (e.g. condensing boiler, CHP or district heating). | |

| − | + | |- | |

| − | + | !colspan="6"|Source: Schmitt, B., 2014. Integration of solar heating plants for supply of process heat in industrial companies (in German language), Dissertation University of Kassel, Shaker Verlag, Aachen, Germany. | |

| + | |} | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

;help topics | ;help topics | ||

Latest revision as of 13:49, 8 January 2015

Back to EFFICIENCY FINDER

- help topics

Back to EFFICIENCY FINDER