Difference between revisions of "Solar application for surface treatment"

From Efficiency Finder

m (Changed protection level for "Solar application for surface treatment" ([edit=sysop] (indefinite) [move=sysop] (indefinite))) |

|||

| Line 1: | Line 1: | ||

Back to [[EFFICIENCY FINDER]] | Back to [[EFFICIENCY FINDER]] | ||

| + | {| class="wikitable" | ||

| + | !colspan="6"|Surface treatment processes are usually characterized by a multitude of bath with different temperature levels. These baths are usually heating separately by internal heat exchangers. Based on the respective boundary conditions, the following integration concepts can be applied. | ||

| + | |- | ||

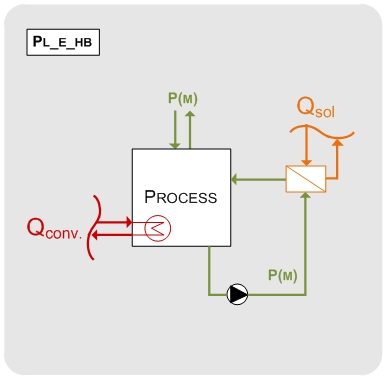

| + | |[[File:PL_E_HB.jpg]] | ||

| + | |'''PL_E_HB - external HEX for heating of bath, machinery, or tank | ||

| − | ''' | + | This integration concept is used to heat baths, machineries, or tanks via an additional external heat exchanger. Therefore, the product or process medium is drawn from the bath, machinery, or tank, heated by solar energy and fed back. It’s crucial for this integration concept to identify a suitable position or point in time within the process where the temperature of the product or process medium is relatively low. Else this concept would lead to a parallel integration of solar heat to the conventional heat supply. If the product or process medium must be kept in a very narrow temperature range (due to operational issues), the resulting temperature difference for solar heating might be very small. |

| + | |- | ||

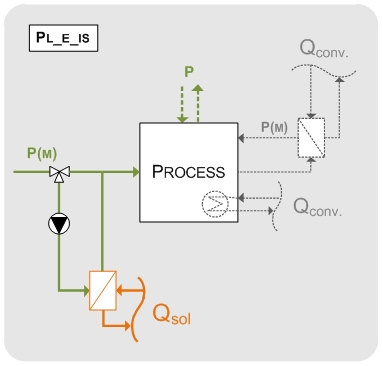

| + | |[[File:PL_E_IS.jpg]] | ||

| + | |'''PL_E_IS - external HEX for heating of input streams''' | ||

| + | The fourth possibility for integration of external heat exchangers is solar heating of input streams. Lots of processes require continuous or batch feed-in of product or process media streams. E.g. feed-in of fresh water for compensation of evaporation losses or fresh air for drying applications. Based on the specific process it can be reasonable to preheat these input streams. The dashed lines within the process flow sheet indicate possibilities for the conventional heating of the existing process. Possibly, this integration concept can be combined with PL_E_PM and PL_E_HB. | ||

| + | |- | ||

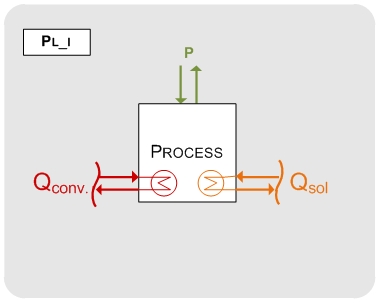

| + | |[[File:PL_I.jpg]] | ||

| + | |'''PL_I- Process level with internal heat exchanger''' | ||

| − | + | The integration of an additional heat exchanger surface within baths, machineries, or tanks is used for the category “heating and maintaining temperature of baths, machineries, or tanks”. Usually, the additional solar driven internal heating surface is installed in parallel to the conventional heat source. For this concept it is important to consider the available space in the process equipment since it is usually limited due to the treated product (e.g. metal parts) or components (e.g. stirrers, strainers, etc.). | |

| + | |- | ||

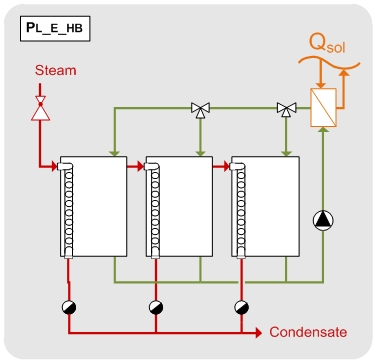

| + | |[[File:PL_E_HB_scheme.jpg]] | ||

| + | |Example how to apply the general integration PL_E_HBscheme to an electroplating process that is heated with steam driven internal heat exchangers. The process medium is draw off the bath and heated by solar energy before it is fed back to the electroplating bath. This leads to a parallel integration of solar heat to the conventional steam heating. | ||

| + | |- | ||

| + | !colspan="6"|Source: Schmitt, B., 2014. Integration of solar heating plants for supply of process heat in industrial companies (in German language), Dissertation University of Kassel, Shaker Verlag, Aachen, Germany. | ||

| + | |} | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

;help topics | ;help topics | ||

Latest revision as of 16:46, 10 February 2015

Back to EFFICIENCY FINDER

- help topics

Back to EFFICIENCY FINDER