Back to EFFICENCY FINDER OF FOOD INDUSTRY

CLEANING

Cleaning of bottles and cases

|

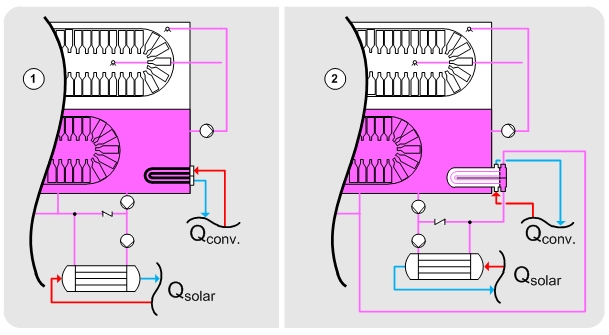

Example how to integrate solar heat for bottle washing machines in beverage companies.

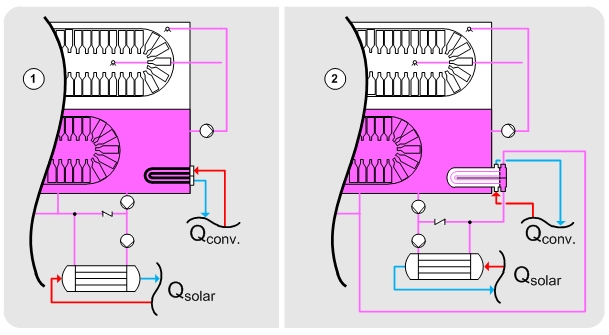

The integration of solar heat for bottle washing depends very much on the type of the installed conventional heat exchanger and its integration into the machine. Bottle washing machines with an internal tube bundle provide the opportunity of overheating the caustic that is withdrawn from the region of the tube bundle, and pumped to the section where bottles enter the main caustic bath (scheme No. 1). At this point of the bottle washing machine, the highest temperature is required, so the caustic can be overheated by solar energy by 3..4 Kcompared to the temperature of the main caustic bath.

Using another tube bundle design, the caustic is removed from the bath and passes the tubes of the bundle. The steam entering the tube bundle heats the caustic within the tubes as well as the entire bath via its shell. A possible way of integrating solar heat in bottle washing machines using this type of heat exchanger is illustrated in scheme No. 2. The solar heat is used for preheating the caustic before entering the tube bundle.

|

|

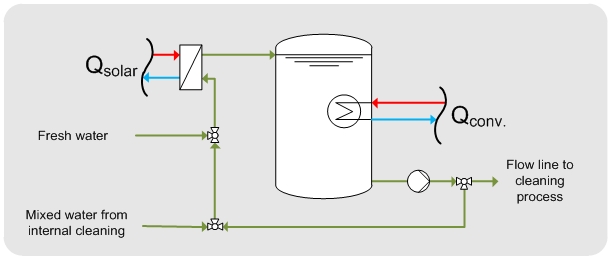

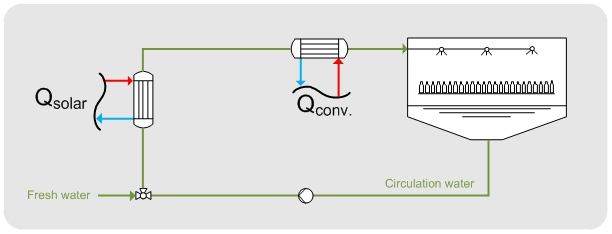

Example how to integrate solar heat for keg cleaning processes in beverage companies.

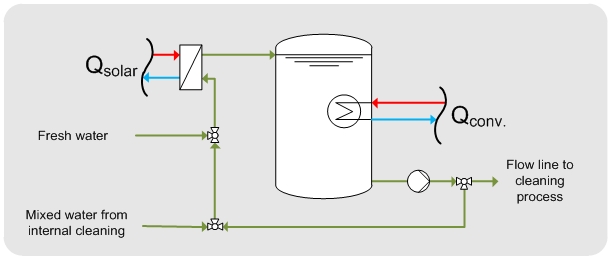

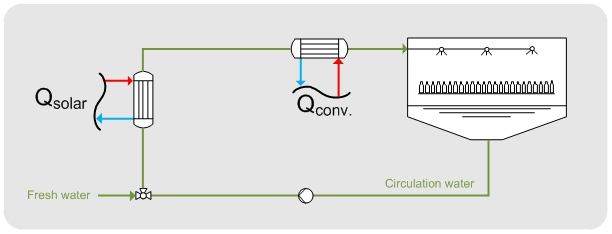

Kegs have to be cleaned from in- and outside. The interior cleaning is done with different spraystations (water, caustic, acid, hot water and steam).Keg cleaning lines have containers for the used media (water, acid, and caustic), which usually are kept at the required temperature by internal heating coils.

To utilize solar heat for keg cleaning, a heat exchanger has to be integrated in the flow line of the respective containers. The Figure illustrates this for a mixed water container. The return flow from internal cleaning is called mixed water and used to clean the exterior surface. Due to the illustrated way of integration, solar heat can be used to heat the mixed water directly while entering the container. The bypass is necessary to utilize solar energy also for heating the container between the cleaning batches. This can be neglected if a keg line is operated continuously.The illustrated integration scheme for heating the container of mixed water can also be applied to caustic and acid tanks. Usually, these media will have higher return temperatures and a cold water inlet is not given.

|

| Source: Schmitt, B., 2014. Integration of solar heating plants for supply of process heat in industrial companies (in German language), Dissertation University of Kassel, Shaker Verlag, Aachen, Germany.

|

Cleaning of production halls and equipment

|

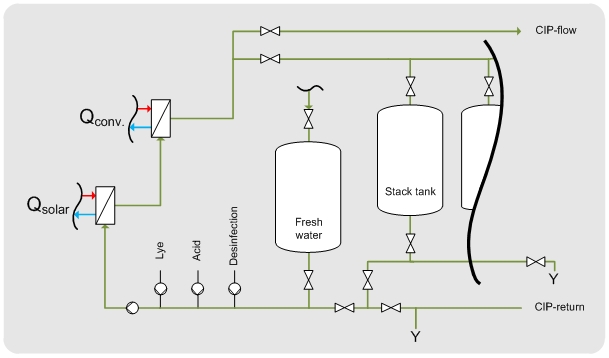

Example how to integrate solar heat for cleaning in place installations (CIP) in Food and beverage companies.

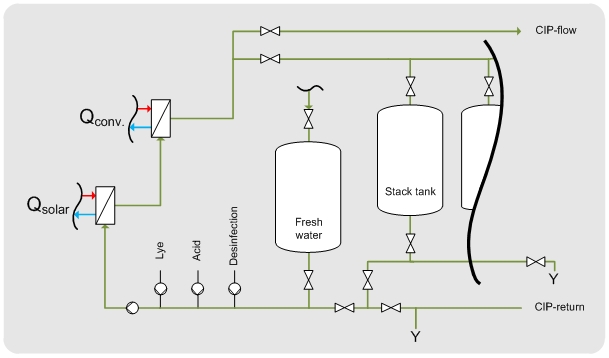

Cleaning-in-Place (CIP) is a method for cleaning process plants without removing single components. Therefore different cleaning cycles (daily to weekly) can be applied. Based on the respective production section, the cleaning is done with cold or hot water. A CIP system consists of multiple recovery tanks for acid, caustic, fresh and hot water, circulation and dosing pumps, one or more heat exchangers, and some other peripherals. CIP systems have often an external heat exchanger, which heats up the various media to the required temperature before they are pumped to the plant components that have to be cleaned. Through a circulation loop, the individual recovery tanks can be heated.

CIP systems with external heat exchangers are suitable for the integration of solar heat. If there are longer periods between the cleaning phases, the recovery tanks can be preheated with a smaller sized solar heat exchanger. If the set temperature is not reached through this measure, the conventional heat exchanger can supply the remaining thermal energy.

|

| Source: Schmitt, B., 2014. Integration of solar heating plants for supply of process heat in industrial companies (in German language), Dissertation University of Kassel, Shaker Verlag, Aachen, Germany.

|

DRYING

EVAPORATION AND DISTILLATION

Evaporation

|

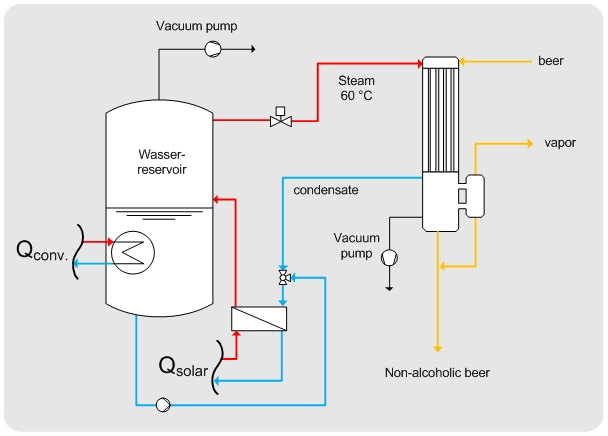

Example how to integrate solar heat for dealcoholization of beer.

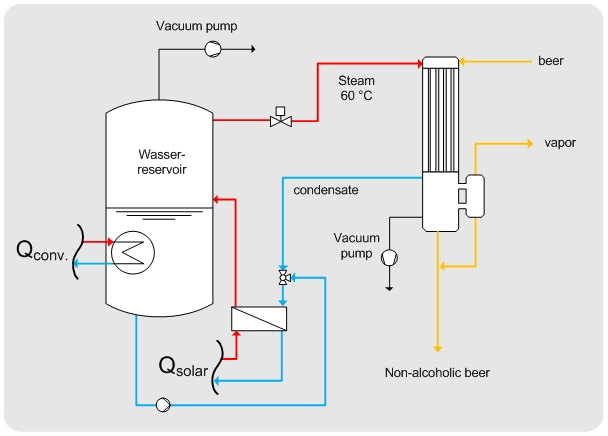

Dealcoholization processes are necessary to meet the growingmarketfor non-alcoholic(<0.05% by volume) andlow-alcoholic beer (<0.5% by volume). In addition to arrested fermentation andreverse osmosis, there are also thermal processesto producenon-alcoholic beers. However, notall breweries producenon-alcoholic beer. Dealcoholization processes are often foundinlarge breweries. The installations areusually designed with relatively low production capacities to maintain long and constant operation times.

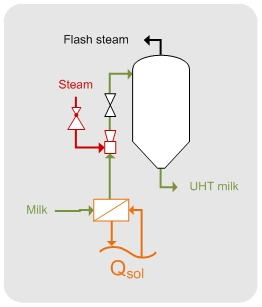

Typical installations used for thermaldealcoholizationare rectification columns,thin film- andfalling film evaporators.Rectification columnsandfalling film evaporatorsare usually designed in multi-stage. Based on the sensitive product characteristics, the evaporator is operated with slight vaccum (both, product andheating side). Thereby thedealcoholizationoccursat low temperatures. Usually saturated steam atabout 60 °C is used as heating medium.

A heating systemconsistingof aconventionalheatedstorage, asolar heat exchangeranda vacuum pump are required to assist the dealcoholization process with solar energy.As shown in Figure 9, solar heat is used to preheat the condensate return. In case of insufficient solar irradiation, the condensate temperature can be increased with the conventional heated storage. Due to the illustrated bypass it is possible to use solar heatalready for the start up the plant.

|

| Source: Schmitt, B., 2014. Integration of solar heating plants for supply of process heat in industrial companies (in German language), Dissertation University of Kassel, Shaker Verlag, Aachen, Germany.

|

PASTEURIZATION

|

Example how to integrate solar heat for flash pasteurization.

Flash pasteurization takes place before the bottling of beer. Usually multi-zone plate heat exchangers are used for flash pasteurization. They can have an internal or external heating and heat retention section. Within the first section, the beer is recuperativelypreheated in counter flow by already pasteurized beer. Within the second section of the multi-zone heat exchanger, the beer is heated to pasteurization temperature by a hot water circuit. This additional hot water circuit is heated with steam or pressurized hot water. This is necessary to ensure a gentle heating of the product.

Solar heat has to be integrated to the water circuit prior to the conventional heating.Flash pasteurization systems with external heat exchangers as shown in the figure can be easily supplied with solar heat, since the piping is usually accessible. Water with approximately 70..75 °C leaves the heating sectionduring operation, is heated by solar energy, and if necessary with steam in the external heat exchanger by 3..4 K.

|

|

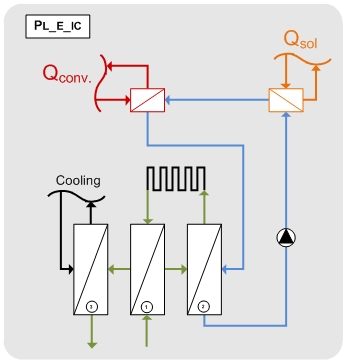

Example how to integrate solar heat for a tunnel pasteurizer.

Tunnel pasteurizers are often used in larger breweries. The filled bottles are transported on wide conveyor belts (sometimes on several floors) through the machine while they are sprayed with water. The bottles are preheated by passing several temperature zones within the first section of the tunnel pasteurizer. Within the middle section they are heated up to pasteurization temperature and kept at this temperature for a defined time. The bottles are cooled downwithin the last section.

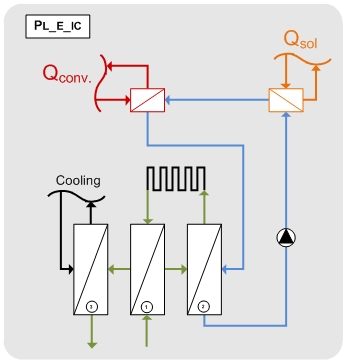

Usually, tunnel pasteurizers have an internal heat recovery. The water that is heated within the recooling zone by the pasteurized bottles is used within the first section to preheat the bottles that enter the tunnel pasteurizer. Only the middle section with the highest temperature level has to be heated conventional. Therefore, one or more external heat exchangers are usually installed. The overall heating demand of tunnel pasteurizers consists of three parts:Heat is required to heat all baths to the required temperature before production. Since there is no heat recovery between the equivalent zones,the maximum power requirement occurs during start-up. In stationary mode of operation the heat demand is limited to increase the temperature of the bottles by approximately 10..15 K within the middle section.

Usually, the baths of the different temperature zones are heated externally. In this case, solar heat can be used to increase the return temperature as shown in the figure. New systems can be equipped with a multi-zone heat exchanger for solar and conventional heating. Due to evaporation and carryover, there is an additional demand of fresh water (up to 20 ml per bottle), which can also be heated by solar energy.

|

| Source: Schmitt, B., 2014. Integration of solar heating plants for supply of process heat in industrial companies (in German language), Dissertation University of Kassel, Shaker Verlag, Aachen, Germany.

|

STERILIZATION

|

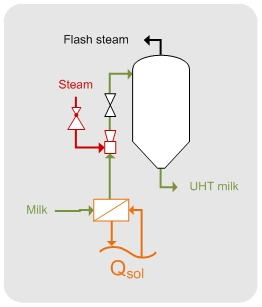

Example how to integrate solar heat for sterilization of milk (UHT Processing).

For UHT Processing steam is injected into milk to heat it up to sterilization temperature (> 135 °C). Following, the milk-steam-mixture is fed into an expansion vessel to remove separate steam and milk. Solar heat can be used to preheat the milk before steam injection.

|

|

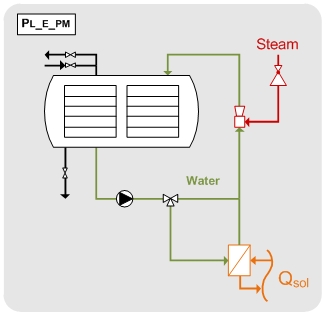

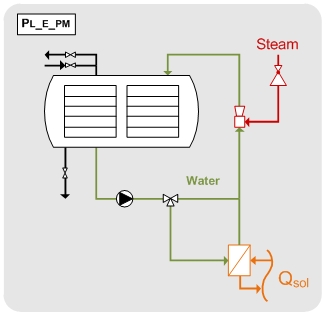

Example how to integrate solar heat for sterilization of canned food via autoclaves.

Within the conventional system the water of the autoclave is heated by steam injection and fed back into the autoclave. The water flow can be separated and partially heated by solar energy to reduce the conventional steam demand for the sterilization process.

|

| Source: Schmitt, B., 2014. Integration of solar heating plants for supply of process heat in industrial companies (in German language), Dissertation University of Kassel, Shaker Verlag, Aachen, Germany.

|

GENERAL PROCESS HEATING

Boiler feed-water preheating

COOLING PROCESSES

Cooling, chilling and cold stabilization

Solar Powered Refrigeration

Solar powered refrigeration systems capable of providing temperatures as low as -23°C have been demonstrated.

(Solar driven) ejector refrigeration System

Ejector or jet pump refrigeration is a thermally driven technology that has been used for cooling applications for many years. In their present state of development they have a much lower COP than vapour compression systems but offer advantages of simplicity and no moving parts. Their greatest advantage is their capability to produce refrigeration using waste heat or solar energy as a heat source at temperatures above 80°C. Applications in the food sector will be primarily in areas where waste heat is available to drive the ejector system. Such applications can be found in food processing factories where the ejector refrigeration system can be used for product and process cooling and transport refrigeration. Other possible application is in tri-generation where the ejector refrigeration system can be used in conjunction with combined heat and power systems to provide cooling.

Back to EFFICENCY FINDER OF FOOD INDUSTRY