Thermofixation in textile industry

Back to EFFICIENCY FINDER FOR TEXTILE INDUSTRY

1. OBJECTIVE

The purpose of heat setting is to dimensionally stabilize fabrics containing thermoplastic fibres (BAT for the Textiles Industry, July 2003).

2. FIELD OF APPLICATION

Polyester and nylon are the principal fibres involved (BAT for the Textiles Industry, July 2003).

3. DESCRIPTION OF TECHNIQUES, METHODS AND EQUIPMENT

- General description: (BAT for the Textiles Industry, July 2003)

Blended polyester/cotton fabrics are produced in large quantities. These fabrics may shrink, or otherwise become distorted either during wet processing or in the consumer's hands. Heat setting is a way of reducing or eliminating these undesirable properties. The process is relatively simple - pass the fabric through a heating zone for a time and at a temperature that resets the thermoplastic fibre’s morphology memory. The new memory relieves the stresses and strains imparted to the fibre by the yarn making and weaving processes, and makes stable the configuration it finds itself in flat smooth fabric. This newly imparted memory allows the fibre to resist fabric distorting forces and provides a way to recover from them. The time and temperature needed for the heat treatment depend on fabric density and previous heat history of the polyester. Time and temperature must exceed that imparted by previous heat treatments. Usually 15 - 90 seconds at temperatures of 196 – 213° F will suffice. The heat setting equipment can be hot air in a tenter frame, or surface contact heat from hot cans. While the process is simple, careful control is required.

- Points of Concern: (BAT for the Textiles Industry, July 2003)

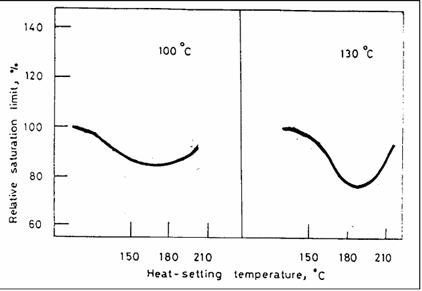

Heat setting reduces polyester's dye up-take. Heat-set goods dye lighter and slower than non heat-set good. For uniform shades, side to centre, front to back and beginning to end exposure to heat must be controlled and uniform, otherwise these differences will show up in the dyed cloth. Heat-setting can be done either at the end of wet processing or at the beginning. At either point, the goods must be free of wrinkles and other distortions otherwise the distortions will be permanently set. Care must be taken when heat-setting greige goods sized with polyvinyl alcohol. At high temperatures, PVA will dehydrate, becoming discoloured and insoluble in water. While greige heat-setting may be particularly beneficial when preparing easily distorted fabrics, one may have to settle for less than the full heat-setting benefit in order to still remove the size. For these cases, alternate mechanical handling preparation equipment may be the answer. Heat-setting harshen the hand and stiffens the fabric. The condition is more prone to happen when contact heat is used. The fabric may become flatter and develop an unwanted gloss or sheen.

4. COMPETITIVE TECHNOLOGIES AND ENERGY SAVING POTENTIALS

- a) Changes in the process

No information is available.

- b) Changes in the heat supply system

No information is available.

- c) Changes in the energy distribution system

No information is available.

Effect of Heat-setting on Dye Uptake:

Literature: Chemistry and Technology of Fabric preparation and finishing; Dr. Charles Tomasino, Department of Textile Engineering, Chemistry & Science, College of Textiles, North Carolina State University, Raleigh, North Carolina, 1992.