Cooling, chilling and cold stabilization in dairies

From Efficiency Finder

Back to EFFICIENCY FINDER FOR FOOD INDUSTRY

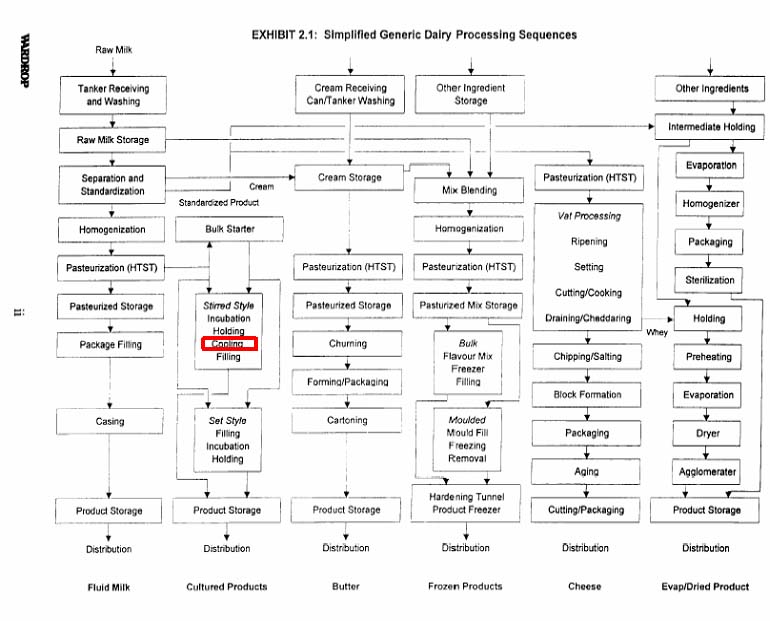

- Applications

Cooling is typically used after processing (e.g pasteurization, sterilization, standardization) of intermediate milk products. Cold storage is also applied to milk products because they are heat sensitive.

- Case studies

- Example flowsheet

Literature: Guide to Energy Efficiency Opportunities in the Dairy Processing Industry, National Dairy Council of Canada, June, 1997

- Typical parameters of the process

| Milk products | Temperature [°C] | Pressure (bar) | Heat absorbing medium | Residence Time | Details | Literature |

| Milk and cream | 4 | raw milk storage | ? | |||

| <7 | cooling after pasteurization | BAT in Food, Drink and Milk Industries, June 2005 | ||||

| Yogurt | 40-43 | milk cooling after pasteurization | BAT for Food, Drink and Milk Industries, June 2005 and Dairy science and Technology, University of Guelph, http://www.foodsci.uoguelph.ca/dairyedu/home.html | |||

| 15-20 | cooling of coagulated product | |||||

| Other fermented milk products | 20-25 | milk cooling before addition of starter culture | Dairy science and Technology, University of Guelph, http://www.foodsci.uoguelph.ca/dairyedu/home.html |